Enhancing Compressive Strength of Pervious Concrete for Use as Pavement Layer in Urban Roads Aper

Volume 9, Issue 1, Page No 49-66, 2024

Author’s Name: Pontsho Penelope Mokgatlaa), Ramadhan Wanjala Salim, Julius Ndambuki

View Affiliations

Civil Engineering Department, Tshwane University of Technology, Tshwane, 0001, South Africa

a)whom correspondence should be addressed. E-mail: pmokgatlap@gmail.com

Adv. Sci. Technol. Eng. Syst. J. 9(1), 49-66 (2024); ![]() DOI: 10.25046/aj090106

DOI: 10.25046/aj090106

Keywords: Pervious Concrete, Permeable Concrete, Dolomite Rock Aggregates, Void Content

Export Citations

South African Drainage and Stormwater Systems in urban roads has been of great concern, more so with recent flash floods in Gauteng and KwaZulu Natal Province in South Africa. Pervious concrete can be used to mitigate these challenges for urban roads. Pervious concrete is a concrete that contains no fines or only a small amount is added for binding. It consists of single sized rounded aggregates between 9.5mm to 12.5mm and bonded by cement and water at points of contact to create a high porosity system that drains water. The research focused on developing different structural pervious concrete mixes, with varying (a) aggregate sizes (7mm, 9.5mm and 19mm) (b) including (river fine aggregates, rubber flakes, fly ash and steel reinforced fiber) and combinations thereof. Results indicated that strong pervious concrete mixes can be developed using a combination of 9.5mm aggregate, river fine aggregates and fly ash, with a recorded maximum yield of 25MPa, and an accompanying Voids Content of 16%. Furthermore, against this performance, it was found that final compressive yield strength of 25MPa falls shy of the 35MPa COTO standard specifications for road and bridge works for south African road authorities (2020 edition). The derived pervious concrete mix was found to satisfy Class 4b Minor Collector Arterial in urban zones, with capacity to withstand up to 10 000 Average Daily Traffic

Received: 26 July 2023, Revised: 19 November 2023, Accepted: 19 November 2023, Published Online: 20 January 2024

1. Introduction

Urbanization, which is concentration of population and its activities (social, cultural, and economic), has resulted in people moving from rural areas to urban in the quest for better opportunities as well as to develop the economy. Other urban benefits include quality health care and services such as (water, sanitary and transport). Unfortunately, with all these benefits some environmental aspects are affecting the very quality of life that was pursued due to congestion, pollution and a huge demand on water, electricity, and infrastructure. Urban areas are extensively covered by concrete, asphalt and infra-structure which makes it difficult for water to infiltrate the ground resulting in increased floods, run-off and contaminated groundwater [1]. The use of pervious concrete has increased with time to reduce some of these environmental concerns. The history of pervious concrete dates to 1800s when Europe was experiencing scarcity in cement as well as cost increase associated with sourcing cement, during this period it was used for pavement surfacing and for load bearing walls. Post WWII in the 1920s the use of pervious concrete increased in both Scotland and Europe due to then again scarcity of cement, in this period pervious concrete was also utilized for slabs in double storey homes.

Pervious concrete is a concrete that contains no fines or only a small amount is added for binding. It consists of single sized rounded aggregates between 9.5mm to 12.5mm and bonded by cement and water at points of contact to create a high porosity system that drains water quickly. Its water to cement ratio is between 0.28 to 0.40 with the voids space between 15-30% where Conventional concrete has 3-5% voids spaces, and it has between 0.18-0.23 ratio of cement to aggregates. This voids space promotes water infiltration whilst recharging ground water with cleaner quality water. Even though it has high voids when placed properly a strength between 3.5MPa-20.5MPa are achievable. Pervious concrete has been developed to be both, firm and permeable, allowing vehicles to travel over it and water to infiltrate. Pervious concrete’s characteristic of high drainage capacity unfortunately does not correspond with stability, durability and strength thus limiting its application to areas that have minimum to no traffic. Pervious concrete mixture has a very low slump because of its low mortar content as well as small number of fines if present at all. This research aimed to modify the standard pervious materials to achieve required compressive strength whilst maintain its pervious concrete benefits of draining water quickly for a wide usage by modifying materials with the information provided by previous studies [2]

1.1. Pervious Concrete Background

Pervious Concrete (PC) is a concrete that contains no fines and only a small amount can be added for binding. It is a zero-slump concrete, consists of single sized aggregates between 9.5mm to 12.5mm and bonded by cement and water at points of contact to create a high porosity system that drains water quickly. Its water to cement ratio is between 0.28 to 0.40 [3] with the voids space between 15-30% [4] where conventional concrete has 3-5% voids space, and it has between 1:4-1:4,5 [5] ratio of cement to aggregates. This voids space promotes water infiltration whilst recharging ground water with cleaner quality water.

The use of Pervious Concrete on pavement in urban areas has very favourable environmental outcomes which forms part of Best Management Practice (BMP). The use of PC may drastically reduce drainage infrastructure required which will aid South African economy. As Engineers it is our responsibility to consider the future effects of our work and the human and environmental impacts. Pervious Concrete has been in use for decades but very limited use due to its strength and durability limitation. It has been listed as BMP because of its environmental benefits in other countries and it is important to enhance its materials based of previous studies to see how it may be used broader that its current limited use. Pervious Concrete limitations are mostly because of its strength and durability, studies have been ongoing to improve with various enhancing materials such as Fly ash, Fibers, waste rubber, Latex polymer, Styrene Butadiene rubber and Fine aggregates [6]-[8]

Characteristics

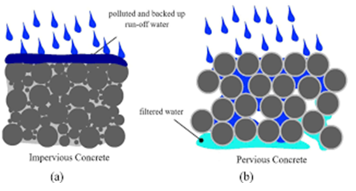

As illustrated in Figure 1, Pervious Concrete also known as porous concrete, or permeable concrete, differs from conventional concrete. It is very permeable with void content range between 15% – 30 % which allows water to seep through the pavement layer directly infiltrating the ground. This water can be harvested, directed to the stormwater existing structures, or simply allowed to recharge the ground. Pervious Concrete’s permeability properties make it an environmentally friendly solution, which explains why it is being utilized in various ways such as sidewalks, driveways and low traffic roads and considered for medium to high traffic roads. The current asphalt roads are impermeable and water exposure is one of the risks especially when the drainage systems are poorly maintained or not available. After rain fall potholes are not visible which poses a risk on the drivers and pedestrians. The runoff caused by rain fall causes splashes on the roads which affects visibility. South African municipalities have limited budget which is always a project constrain and by opting for pervious concrete the amount of stormwater infrastructure will be reduced which thus reduce cost. The study focused on urban roads which are the most affected by floods, runoff, insufficient draining infrastructure which was the focus for the research to enhance Pervious Concrete with affordable and locally sourced materials.

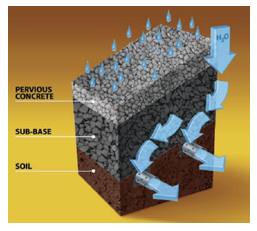

The current road designs protect road layers from water however it is impossible to prevent water damages, water being in solvent given time water destroys even the most permanent looking structures such as asphalt roads. Pervious Concrete as illustrates on Figure 2 allows water to infiltrate the ground and by design water doesn’t pond which all more reason to enhance the strength and durability of Pervious Concrete to benefit rural roads, urban roads even highways.

Figure 1: Pervious Concrete (American Society of Civil Engineers)

Structural layout

Pervious concrete is commonly used for walkway and driveway however Pervious Concrete has a potential to reduce stormwater runoff, road splash and sprays, Pervious Concrete needs to be improved to meet the required strength and durability to be considered as a road pavement layer. This research focused on using Pervious Concrete as more than what is currently being utilized for by improving its mechanical properties. With all the pervious concrete has, it should not be limited to just walkways, driveways and so forth however be extended to urban roads.

Figure 2 Pervious Concrete Pavement Drain ability (Source: Quick Mix Website)

a) Pervious Concrete layer

Pervious Concrete layer is the top layer that is exposed to the environment and traffic. The thickness of this layer ranges between150 mm to 200mm see above Figure 3. Pervious Concrete layer must be strong and capable to withstand traffic and must be durable to all types of weather. Figure 3 Above shows the structure of Pervious Concrete pavement layers used for parking lots and sidewalks. Though the above structure is for no traffic areas, the similar structure enhanced will extend the use of Pervious Concrete and economy which is what the research aimed to achieve. The pervious concrete layer has 15-30% void content and between 3.5-20.5Mpa compressive strength.

Figure 3: Pervious Concrete Pavement Structure (Image Curtesy of Quick Mix Website) and Sika USA

b) Sub- base layer

The sub- base layer as shown in Figure 3 above has 20% to 40% voids and must be constructed uniformly at a correct elevation to provide support and it has to be sloped correctly to allow water flow to catchment areas. Other studies recommend compaction but not extreme levels following the natural drainage pattens. The designer can specify geotextile on the sub- base layer after compaction though not mandatory but preferred when sub-grade layer is of fine material.

c) Sub-grade layer

Soil-layer which is the undisturbed soil beneath sub-base see Figure 3 which its purpose is to provide support and store infiltrated water, this layer too must be constructed evenly and to the correct level and desired slope. The soil layer may consist of fine material with low permeability, this does not affect construction of Pervious Concrete however a geo-textile may be required in between the sub-base and sub-grade to mitigate clogging and reduced retention capacity.

1.2. Problem Statement

Stormwater runoff is one of the greatest issues in South African urban roads which has caused environmental problems such as roads and embankments erosion whilst damaging properties and adding to pollution concerns. There are measures that have been put in place to mitigate stormwater runoff issues such as (surface drainage, open channels, stormwater pipe, culverts, and bridges) however none of the efforts has been sufficient to resolve this problem. Pervious Concrete is a highly permeable concrete which promotes water infiltration. The use of it would control surface runoff exposing damages on the road such as potholes during and after rainfall and reducing road ponding water sprays. Pervious Concrete doesn’t just benefit the environmental but the economic too by saving cost on the stormwater infrastructures, reduce the risk of floods, help control stormwater runoff. Cities and Municipalities have budgetary constraints that can be addressed by constructing roads that have stormwater management benefit reducing the requirements additional stormwater infrastructure.

1.3. Specific objectives

- To evaluate the influence of compaction on compressive strength of Pervious Concrete made with dolomitic rock coarse aggregates.

- To ascertain / establish the quantity of fine aggregates required to enhance the compressive strength of Pervious Concrete which usually doesn’t contain fine aggregates or any fine aggregates.

- Determine the impact of waste tyre rubber when included in a Pervious Concrete mix and calculate the quantity required to enhance the mix.

- Derive a combination trial mix that will enhance the compressive strength of Pervious Concrete.

- To compare the achieved compressive strength results of the modified Pervious Concrete made with dolomitic rock aggregates against TRH 26 (South AfricanRoad Classification andAccess Management Manual) and determine road class will the achieved mix satisfy.

To achieve maximum permeability large stones are required because large aggregates sizes create larger voids thus promoting permeability. However large voids are the reason that Pervious Concrete is low in compressive strength. Literature indicates the use of fine aggregates in small quantities has been shown to enhance and improve the strength of Pervious Concrete. In the quest of sustainable engineering ongoing studies to enhance Pervious Concrete by partially/fully replacing standard material with enhancing materials [10].

Though efforts have been taken to study and enhance Pervious Concrete, little is still known about Dolomite rock coarse aggregates Pervious Concrete which was the motivation of this research also being mindful of cost and availability of dolomite rock in South Africa. The objective of this research was to enhance Pervious Concrete from its typical compressive strength of 20Mpa to higher compressive strength that can be suitable for urban roads whilst maintaining sufficient void content (15-30%) to drain efficiently.

2. Materials and Methods

Coarse aggregates make up the largest material and provides the overall strength of Pervious Concrete mix, therefore the type of aggregate influences performance and strength. Pervious Concrete has high permeability due to high void content and low mortar content therefore the aggregates have to provide both structural integrity to withstand the traffic loads and environmental conditions whilst allowing water infiltration and drainage. Pervious Concrete uses the same materials as the conventional concrete however Pervious Concrete has no fines. Crushed natural stones are usually used, some studies experimented on river stones, limestones and few on dolomitic stones. The choice of coarse aggregates is thus very important as it plays an important role in forming both the critical mass and bonding component. The size, type and shape of coarse aggregates are also important because they have influence on permeability rate, compressive strength, and durability [11].

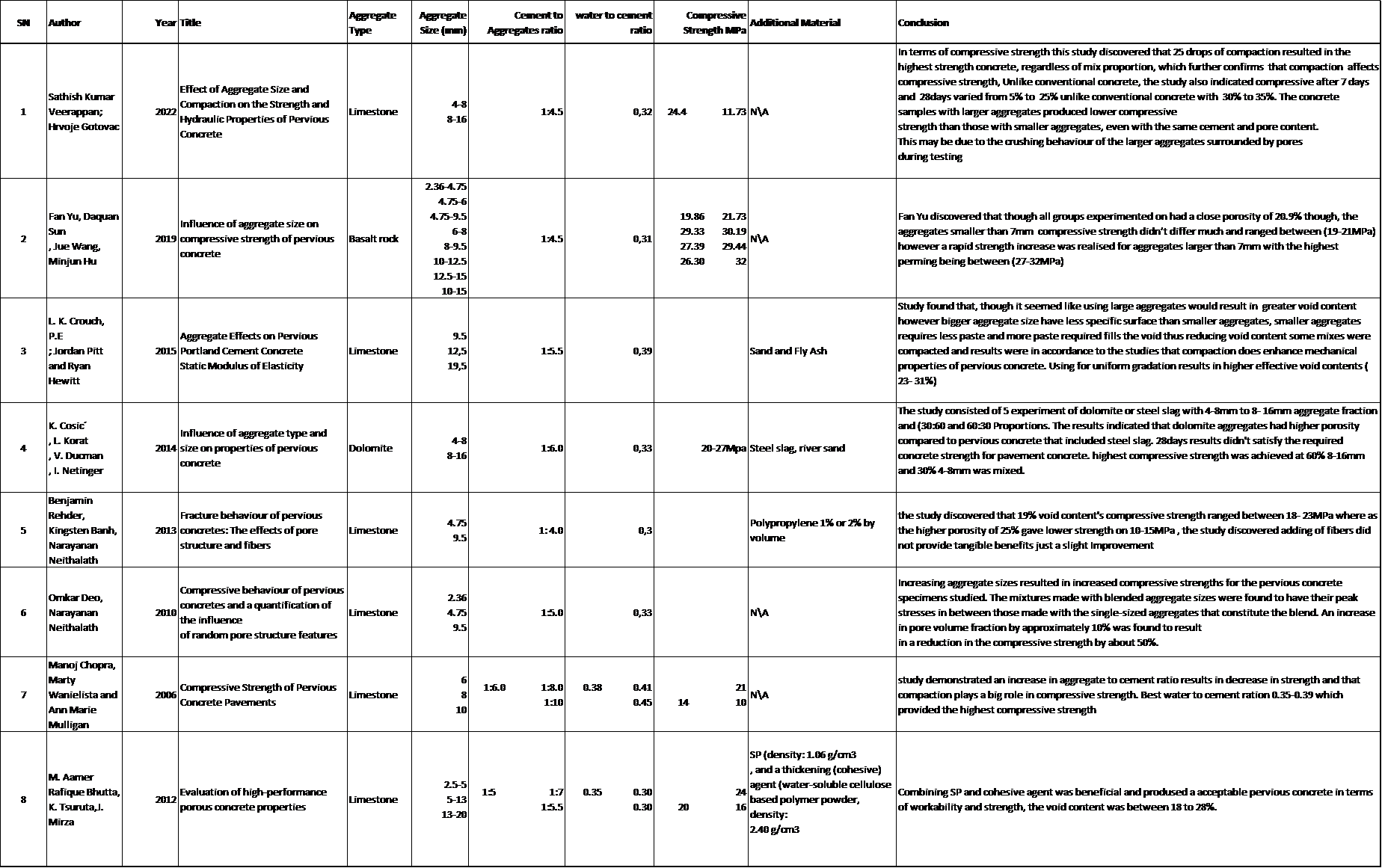

2.1. Literature Summary Table

Table 1 Literature Summary on Aggregate size, water to cement ratio and aggregate to cement ratio.

Study by [12] discovered that single size 9,5mm natural Crushed stone aggregates yielded the highest compressive strength, whilst other studies discovered that aggregates lower than 7mm stone didn’t show a significant change in compressive strength it ranged between 19- 21Mpa. Aggregates larger than 7mm showed a big increase in compressive strength with the increase in aggregate sizes. 6-8mm stone had a compressive strength of 29.33Mpa and 32Mpa for 10-15mm stone aggregate size indicated that the bigger the aggregate size doesn’t necessarily result in higher compressive strength, what it seemed to increase was permeability due to larger void space [13].

Based on Table 1 of past literature on aggregate sizes of Pervious Concrete. This research focused on the dolomite rock coarse aggregates 7.1mm, 9,5mm and 19mm to determine if the dolomite rock will behave the same as limestone or river coarse aggregates. Dolomitic rock is affordable and readily available in Gauteng province.

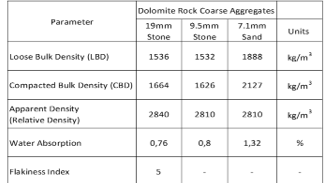

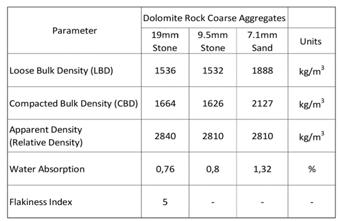

Table 2: Coarse aggregates properties

2.2. Dolomitic Rock

Above Table 2 shows the properties of dolomite rock sourced at PPC Group. There are limited studies on dolomitic rock. Dolomitic rock has high surfaced hardness as well as density, it also has low water demand which is of benefit since Pervious Concrete has limited water. [14,15] studies indicated improvement in compressive strength due to the dolomitic rock’s high resistance to abrasion and to attrition another study indicated using Pervious Concrete with dolomitic rock as coarse aggregates resulted in improved durability and long-term performance in comparison to with other types of aggregates and it requires less energy to produce compared to other types of aggregates. Gauteng Province has 25% of its land covered in dolomitic rock [16], with upgrading, extensions and new infrastructure on the rise and this type of aggregates being locally discarded material due the risk related to foundation problems and groundwater, makes dolomitic rock very affordable.

There are limited studies on Pervious Concrete with dolomitic rock as coarse aggregates and no studies modifying dolomitic rock Pervious Concrete with either fine aggregates, fibers, or admixtures. Studies that have used dolomitic have shown impressive results.

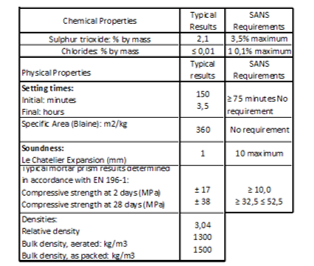

2.3. Cementitious Binders

Portland cement is the most used in Pervious Concrete have a very important role in construction and just as important in forming Pervious Concrete, it is mainly used as an aggregate binder that sets and hardens due to a chemical reaction between the dry ingredients and water it is rarely used on its own. Cement is an ingredient of concrete. It is a fine powder composed of crushed rock with burnt lime which behaves as a binder when mixed with water, coarse aggregates, and fine aggregates [17]. Table 3 shows the chemical and physical properties of cement used.

Table 3: Chemical and Physical Properties

Cement water ratio and cement to aggregate ratio are very important in Pervious Concrete, the ratio will determine the compressive strength. Water to cement influences workability, permeability, and strength, it is key to strike a balance. If the paste is too little the mix might not mix well or reach required consistency, when it is too high it settles at the bottom without providing adequate bonding. Pervious Concrete tends to fail at the interface between aggregates, water and cement which results in low compressive strength, studies have demonstrated that the higher the cement water ratio produces low compressive strength. It is important to note that by making paste stronger does not result in overall increased strength. The cement paste volume influences permeability, excessive paste fills the voids increases the strength however eliminates permeability which will take the number one benefit of pervious concrete being very porous. The use of admixtures by partially replacing cement has indicated, improved workability, shrinkage, reduced bleeding, improved long term durability and strength. To achieve optimal strength of the cement paste, proper curing has to be ensured to allow the paste to reach its full potential strength.

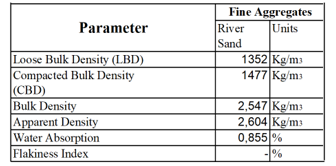

2.4. Fine aggregates – Fine Aggregates

Pervious Concrete also known as zero slump and no fines concrete as it usually doesn’t contain fine aggregates to allow large void formation. In attempts to enhance Pervious Concrete studies indicated that the use of fine aggregates in small quantities improves strength, resistance, and durability. Above Table 4 shows fine aggregates properties. The reason adding fine aggregates has proven beneficial is by adding fine aggregates increases connecting points of pervious concrete thus providing a stronger bond [18] Fine aggregates inclusion increases mechanical properties of pervious concrete however reduces void content, it important to add enough fine aggregates to balance both void and strength. Fine aggregates inclusion improved workability, when fine aggregates particles filled the voids between coarse aggregates provides better bonding and interlocking thus improving workability, placing as well as compaction.

Table 4 Properties of Fine Aggregates (Fine aggregates)

Pervious Concrete does not include fine aggregates or aggregates less than 3mm for large voids formation to create a highly permeable surface, previous studies have shown that adding small amount between (5-10%) of fine aggregates may balance Pervious Concrete strength and permeability. The research experiment aimed to enhance Pervious Concrete made with dolomitic rock coarse aggregates by varying different fine aggregates percentages in Pervious Concrete, results have shown that fine aggregates enhance mechanical properties of Pervious Concrete.

2.5. Fly Ash

Table 5 below shows properties of Fly Ash that was sourced from PPC Group

Table 5 Fly Ash Properties

| CLASSIFIED FLY ASH

Finer Ash which further selected/Split from the classifier |

| Class (S) Fly Ash (CFA)

Used as a partial cement replacement when making concrete or cementitious products, because of its Finer properties it offers an accelerated reaction to the solution.

|

An admixture is defined as “a material other than water, aggregates, cementitious materials, used as an ingredient of a cementitious mixture to modify its freshly mixed, setting, or hardened properties and that is added to the batch before or during its mixing.

It is possible to produce concrete without concrete without cement and substitute it with fly ash as binder. Fly ash is a by-product from coal combustion when generating electricity, this material is waste and cannot be used to generate power. The benefits of fly ash concrete such as improves workability on fresh concrete and accelerates ultimate strength on concrete and minimises thermal cracking [19].

Admixtures can be both natural and manufactured and benefits both fresh and hardened concrete. Previous studies managed to enhance and improve concrete strength significantly by adding (a) silica fume and (b) superplasticizer admixtures, further proving the significance of admixtures in Pervious Concrete. Studies summarized in Table 1 measured the effect of using fly ash and fine in Pervious Concrete and performance benefits and the study indicated that cement can be reduced up to 10% in Pervious Concrete without affecting or compromising permeability or strength. Fly ash inclusion reduced water demand which is a benefit due to limited water requirement in pervious concrete and fly ash improved workability since it acts as a pozzolan enhancing the cohesiveness of pervious concrete. Fly ash inclusion reduces the costs as because it is very cheap waste product. [20] demonstrated that partial replacement of cement with fly ash improved strength, resistance and durability by forming additional calcium silicate hydrates during hydration process and the pozzolanic reaction results in refined and denser microstructure.

2.6. Steel Fiber

Steel fibre for reinforcing concrete is defined as short, discrete lengths of steel fibres with an aspect ratio (ratio of length to diameter) from about 20 to 100, with different cross-sections, and that are sufficiently small to be randomly dispersed in an unhardened concrete mixture using the usual mixing procedures. Table 5 provides information on the steel fibres used from ANVILS South Africa.

Steel fibers are very small and thin strands made of steel, the use of steel fibers in Pervious Concrete are ongoing and the available studies results indicates improvement on mechanical properties of Pervious Concrete by providing reinforcing to Pervious Concrete which is important for this highly permeable pavement. literature results indicated following results (improved workability, increased strength and durability, crack resistance) when steel fibers are used [21]-[25].

Pervious Concrete’s greatest benefits is being porous by having large voids, yet it is the reason that Pervious Concrete mechanical properties are compromised and require reinforcing without affecting to allow water to infiltrate the ground through the voids. Study review on the durability of Pervious Concrete reinforced with steel fibers indicated that adding fibres to Pervious Concrete improves both Tensile Strength and Permeability and this was due to fibres slightly increasing the void content in the mix. The study also indicated an increased void content, whilst splitting tensile and compressive strength in Pervious Concrete also improved due to fibres behaving as woven fabric in concrete which provides the structure with some reinforcement. In another separate research study, five (5) different types of fibres were used, three (3) which were non-structural for the reduction of shrinkage, and two (2) were of structural components to enhance mechanical performance. The compaction energies and w/c ratios differed for the various mixes, whilst aggregate size remained the same. The results showed an overall significant improvement in Pervious Concrete’s strength. There is risk in using steel fiber in Pervious Concrete such as corrosion which may result in affecting the strength and durability hoped for when utilised, this however can be mitigated. The reason steel fiber rust is due to the exposure to environmental elements, air and water which results in the surface of the steel fiber corroding oxidisation. Ways to mitigate this or extend the lifespan of steel fiber reinforced Pervious Concrete are using stainless steel fibers as they are more resistant to rust, using zinc or aluminium coated steel fibers to prevent direct exposure on the steel fiber. Placing of fiber steel reinforced concrete is important, the distribution has to be even, and adequate curing achieved. like any other pavement layer, maintenance is required, and damages repaired. This study focused on the stainless stell fiber to mitigate corrosion.

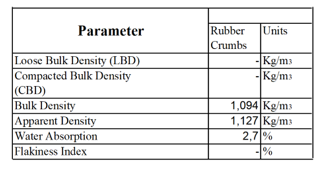

2.7. Waste Tyre Rubber

Waste tyre rubber that was already in crumbs were collected from Dawhi rubber recycling in Germiston. To make sure they were free from oils and dirt, they were washed and properly dried ahead of time below Table 7 shows the waste tyre properties.

Table 7 Waste Tyre Properties

Waste tyres are amongst the biggest waste that is produced yearly. 1000million waste tyres are generated each year with the projected 1200million by year 2030 Disposing waste tyre is a challenge for cities. Studies were done with this waste material as an innovative solution to mitigate the waste tyres disposal challenges not only to recycle but also to enhance the strength of Pervious Concrete by partially replacing coarse aggregates with waste tyre rubber.

The inclusion of waste tyres has been explored however have contradicting information [26] discovered by partially including waste tyres to pervious concrete improved the mechanical properties such as resistance, cracking, ductility, and improved energy absorption. When waste tyres are partially included in a pervious concrete mix, a big reduction in mechanical properties such as compressive strength was experienced, the study indicated that this reduction in mechanical properties was due to inappropriate bonding between tyres and cement resulting in degradation and lack of bonding of the pervious concrete mix. [27] experimented on waste tyre crumbs and natural zeolite to enhance pervious concrete, findings were consistent with waste tyre reduced mechanical properties. A Study by [28] found that by replacing coarse aggregates with 9% of waste tyre improved compressive strength.There are other factors important to the strength and durability of pervious concrete such the following:

2.8. Aggregates grading

Stone aggregate’s grading is just as important when considering the strength factor and permeability, it is important to keep a narrow grading. Poorly graded material requires excessive cement paste for filling up the voids which cannot be afforded on Pervious Concrete as it has a limited cement paste, gap graded is viable grading however is not optimal.

It is important to achieve well graded aggregates, which are aggregates that are proportioned and sized correctly to maximize aggregate volume and preserving workability, finishing and strength. Well graded aggregates provide the highest strength which was the study goal to enhance Pervious Concrete. Pervious Concrete commonly used gradation includes amongst others, most research used ASTM C 33 Sieves, namely (a) No. 67 (Sieves 19.0mm to 4.75mm), (b) No. 8 (Sieves 9.5mm to 2.36mm) and (c) No. 89 (Sieves 9.5mm to 1.18mm), and while up to 25mm single-sized aggregates have also been used. In this research SANS 3001-AG1 Grading Method was utilized which is a commonly used method in South Africa

2.9. Aggregates size

The aggregate size is important as it influences compressive strength, pore characteristic, paste thickness which all affects Pervious Concrete mechanical properties of pervious concrete Coarse aggregates generally consists of 9.5mm to 19mm stone sizes however studies have indicated an inclusion of smaller size aggregates enhances and improves mechanical properties of Pervious Concrete whilst maintaining acceptable water drainage for Pervious Concrete, large aggregates have larger voids which result in high permeability however compromises the concrete strength. Pervious Concrete is commonly used in parking lots, pavements, and low traffic roads where aesthetics matter therefore using the smallest size is useful. The thickness of the paste influenced strength, the thicker the paste the higher the strength. Some indicated that larger aggregates had thicker coating thus indicated that with an increase in aggregate size resulted in higher compressive strength which is a contradiction to most studies see Table 1 which indicated compressive strength reduction with aggregate size increment. Including fine aggregates which are aggregates smaller than 7.1mm in small quantities indicated improvement in mechanical properties with lower yet acceptable draining capacity due to smaller void content. The size choice of Pervious Concrete is key as it will affect permeability rate as well as the strength of the concrete.

2.10. Aggregates shape

Aggregate shape equally plays an important role when considering compressive strength yield in Pervious Concrete. The shape of aggregates in Pervious Concrete directly influences the size of voids. Bearing in mind the shape of the aggregates, when void sizes in concrete increases, permeability increases. With increased permeability however, there is direct negative impact on mechanical strength parameters, leading to the reduced compressive strength of Pervious Concrete. The following are common types of aggregates shape:

- Angular aggregates: These are aggregates with irregular shape, characterized by their sharp edges, also known to provide good interlocking property with large void space and high permeability. The higher the void space means the lower the compressive strength. Angular aggregates also negatively affect workability.

- Rounded Aggregates: Rounded aggregates unlike angular aggregates offers good workability with less water demand. Compared to the angular, round aggregates performed better in terms of compressive strength and permeability. The interlocking of round aggregates is not that greatest which may result in weaker bond, they are also less inter- particle friction which results in reduced resistance.

The shape of aggregates in Pervious Concrete directly influences the size of voids, when void sizes in concrete increases, permeability increases. With increased permeability however, there is direct negative impact on mechanical strength parameters, leading to the reduced compressive strength of Pervious Concrete referred aggregates are the single sized, well graded aggregates which are proportioned correctly to promote maximum aggregate volume, workability, and strength.

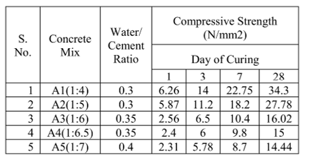

2.11. Cement To Aggregates Ratio

Pervious Concrete is a unique concrete that is very permeable to allow water infiltration. Conventional concrete has high cement content in comparison to Pervious Concrete, the high cement to aggregates ratio of Pervious Concrete is important in creating a porous structure by creating large voids to allow water to pass through.

Table 8 Compressive strength of different Cement to Aggregate ratios [25].

In the quest to improve Pervious Concrete different ratios of cement to aggregate have been experimented on see Table 1 and Table 8 where it shows the compressive strength results. The two tables indicates that the highest compressive strength was mostly achieved when cement to aggregate ratio is 1:4 and between 9mm to 10mm stone aggregate size. Table 8 below shows compressive results of 34.3Mpa for 1:4 Cement to aggregate ratio and for cement to aggregate ratio of 1:7 the compressive strength was lower at 14.4Mpa, the results indicated that the higher the quantity of aggregates increased to one part of cement the compressive strength reduced. Consequently, this means the Aggregate Cement (A/C) ratio can be optimized thorough selecting the required ratio for optimum mechanical properties as well as physical properties (permeability). Research has shown that when higher aggregates amount is used, the concrete needs more water which affects concrete strength unless cement content is adjusted [29.30].

2.12. Water Cement Ratio

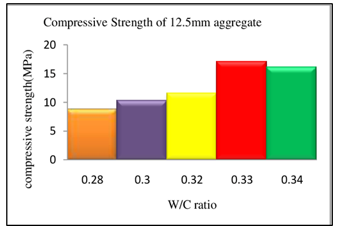

Water-Cement (w/c) ratio which is the weight of water to weight of cement in pervious concrete mix. W/C plays an integral part in workability, permeability, strength, and durability in Pervious Concrete. Lower w/c ratio affects workability however results in higher compressive strength see Table 1. The study by [31] discovered that lower water to cement ratio doesn’t achieve high compressive strength due to poor workability and poor hydration of the cement and poor cohesion between cement and aggregates. Excess amount of water improves workability but negatively affects durability, excess amount of water drains the paste which leads to clogging of the voids. Water content has to be closely monitored. Figure 4 below illustrates compressive strength versus varying water-cement ratio:

The water cement (w/c) ratio generally used in Pervious Concrete ranges from 0.3 to 0.4, and this is sufficient for viscosity, coating, and binding of aggregates. Previous studies have revealed that to achieve an optimum Pervious Concrete mixture, the water-cement (w/c) ratio has to range from 0.32 to 0.34 as demonstrated in Figure 4. Water to cement ratio, though important it does not determine the final concrete’s properties there are more factors just as important such as aggregates quality and grading, mixing time, the use of admixture in the mix, the technique used, compaction and curing method are all key to the performance of pervious concrete. Studies have indicated that by increasing w/c ratio there’s a direct increase in compressive strength, however, reduces permeability. Previous studies have assessed the hydrological and structural performance using the paste thickness and discovered that the thicker the paste resulted in higher compressive strength.

Figure 4 Variation in compressive strength of Pervious Concrete with various water cement ratios (M. Neamitha, T. M. Supraja,2017)

Furthermore, Pervious Concrete tends to fail at the interface between aggregates, water, and cement. Striking a balance between water and cement is just as important since making the paste stronger does not necessarily result in the overall increased compressive strength. Figure 4 indicates that to achieve the highest compressive strength, water to cement has to be 0.33, this is contrary to the studies by [32] where for optimal strength w/c ratio varied between 0.30 – 0.35.

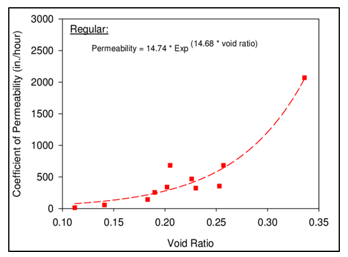

Figure 5 Relationship between pervious concrete void ratio and permeability for all mixes placed using regular compaction energy, (John T. Kevern)

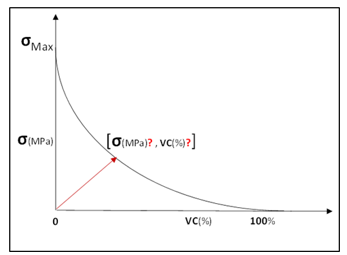

2.13. Acceptable Void Ratios In Pervious Concrete

Figures 5 and 6 illustrate an exponential relationship between Permeability and Void Ratio, and both factors are directly related regarding Pervious Concrete. In other words, an increase in Void Ratio yields an increase in Permeability. In terms of conducted research, Pervious Concrete’s void ratio typically ranges from 15 to 30%. Previous studies have illustrated that a range of 15 to 30% in voids provides acceptable levels of compressive strength, hydraulic conductivity, and permeability results. When the void ratio is lower the unit weight is therefore higher which results in higher compressive strength. Subsequently, the higher the voids content, the more likelihood the mix will pose a lower compressive strength. The following theoretical Figure 5 and 6 illustrates the above-mentioned concept.

Figure 6 Theoretical Compression Strength (MPa) and Voids Content (VC%)

Material Preparation and Handling

This section of the research methodology demonstrates how research material was handled during placing, mixing, and curing. Preparation process involved the following activities in a numerical sequence:

a) Sieving and Weighing

Material was batched according to the aggregate size. A large enough quantity was taken from the batch, cleaned to remove any impurities, material was dried and weighed to sample size then sieved with the shaker in descending size order. The largest sieve was placed at the top and smallest at the bottom, the results captured on each sieve were recorded. Percentages and cumulative percentages on each sieve were calculated and recorded.

b) Moulds Preparation

Mould sizes used were 150mm x 150mm x 150mm laboratory moulds that were cleaned with the wire brush and oiled.

c) Concrete mixing

Mixing was done according to the standard SANS 5861- (2006) using electric mixing drum. One adjustment was made where 5% of the cement was allowed to mix for a minute with coarse aggregate to all coating and improve bonding. The rest of the material was added and mixed for 3 minutes. A consistency check was performed using a ball method for every mix.

d) Concrete Casting and Curing

Specimens were casted according to SANS 5861-3 (2006). To determine the impact of compaction, samples were cast with and without compaction on the 3 sets of coarse aggregate sizes (7.1mm, 9.5mm and 19mm) dolomite rock. Different energies were administered in 3 layers (15, 20, 25) blows. Compacting Pervious Concrete is discouraged however there have been studies that found improved strength with minimum compaction. A tamping rod was used for compacting and levelling.

The curing process was according to SANS 5861- 3 (2006), concrete moulds were placed in a curing bath with heat circulating pump, which kept the temperature at 23 ± 2°C constant throughout the bath.

Figure 7 Laboratory sieved and weighed Material and labelled according to size.

Figure 8 Weighed and sorted material according to the mix design.

Figure 9 Electric Concrete Mixer

Figure 10 Ball Method (PC consistency check)

Figure 11 Cleaned and Oiled Mould.

Figure 12 Compacting with a rod.

Figure 13 Compacted and Levelled Samples

Figure 14 Labelled and Color Coordinated Samples I

Figure 15 Labelled and Color Coordinated Samples II

Figure 16 De-Moulded and Placed in a temperature-controlled bath.

Figure 17 Samples ready for Testing

Figure 18 Sample Testing

Test Methods for Mechanical Properties of Aggregates

2.14. Sieve Analysis

The Standard SANS 201:2008 was utilized for sieve analysis for fine aggregates. Dry material was proportioned and placed in an oven at a temperature of 100 degrees Celsius, then weighed and recorded. Wet sample weight was weighed and recorded, extreme care was taken to wash and decanting until the water was clear. Fine material was dried and sieved again to calculate sieve analysis and fineness modulus.

Sieve analysis for coarse aggregates was performed in accordance with the standard SANS 201 (2008). Aggregates were washed and dried overnight. 19mm coarse aggregates was sieved through a couple of sieves bigger and smaller sieve sizes and only aggregates retained at 19mm sieve were utilized. 9.5mm coarse aggregates were sieved through a couple of sieves bigger and smaller sieve sizes and only aggregates retained at 9.5mm sieve were utilized. 7.5mm coarse aggregates was sieved through a couple of sieves bigger and smaller sieve sizes.

2.15. Bulk and Relative Density

The standard SANS 3001: AG20;2014 for coarse aggregates bulk densities, relative densities and water absorption was used in determining Bulk and Relative Densities of the aggregates. The standard procedure was followed. Aggregates were first sorted according to size and proportioned according to the sample mass stated in the standard. The aggregates were then washed off to remove the dust, and then soaked in portable water for 24hrs. The visibly dried yet damp aggregates mass was recorded. Submerged in wire basket and unstrapped all bubbles and recorded the wet mass were recorded. The drained and dried aggregates were oven dried, and the mass recorded. From the above recordings the bulk and relative density were calculated.

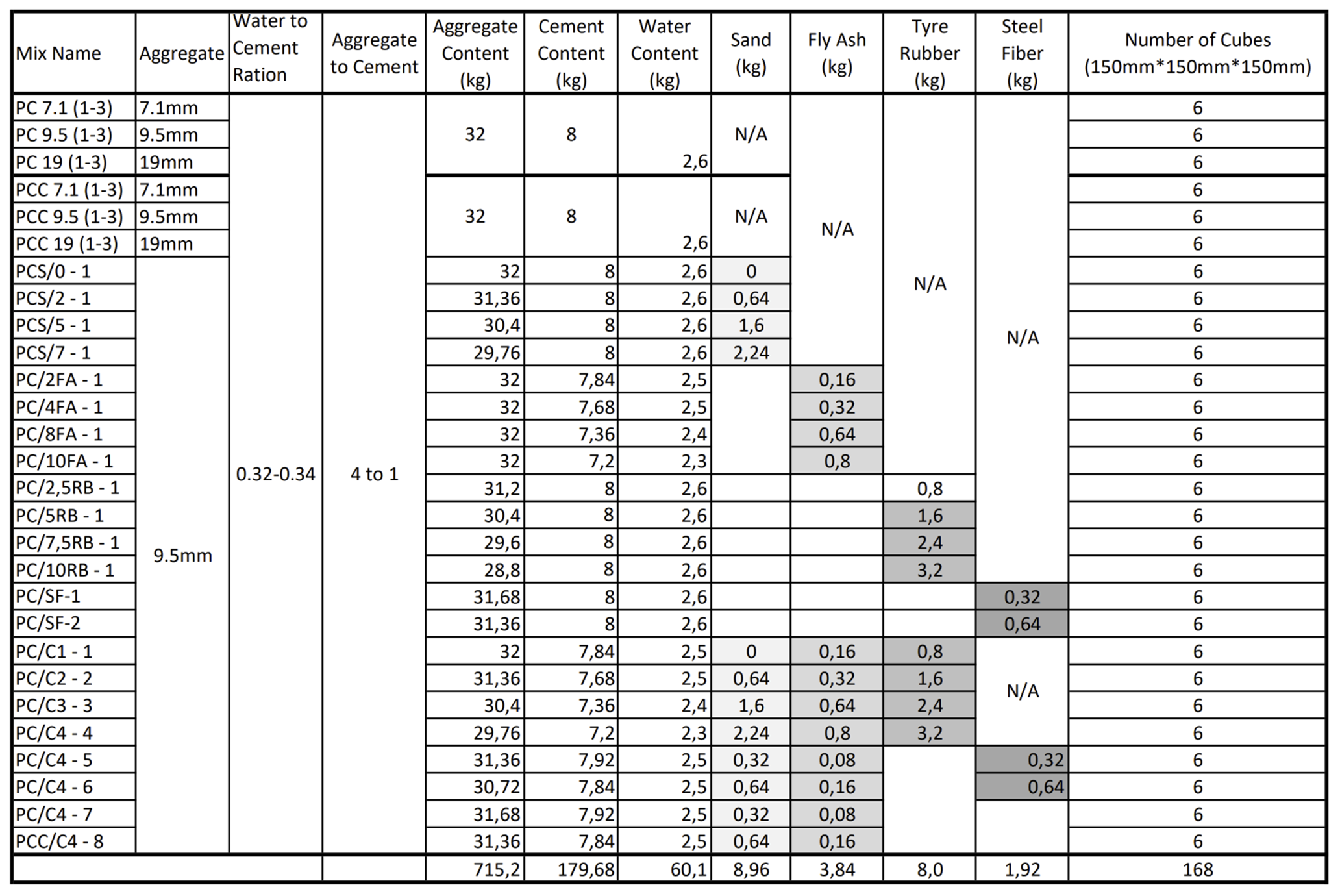

2.16. Test Methods For Trial Mixes

Several trial mixes were made so as to determine which materials will have an impact on Pervious Concrete strength. First a control Pervious Concrete was developed then additional materials were introduced one at a time in different dosages informed by the literature review chapter 2. Later a combination of the best-performing materials was assessed. To develop a strong Pervious Concrete mix, testing had to be classified into different testing phases, whereby different materials (fine aggregates, tyre rubber, steel fibers) discussed in literature review chapter, their content in terms of volumetric percentages, different combinations, and performance thereof, had to be explored. Consequently, materials were eliminated as they proved to weaken the Pervious Concrete mix. And on the contrary, admixtures enhancing strength were adopted and optimized further.

2.17. Fresh And Hardened Concrete Test

Slump test is not effective for Pervious Concrete because Pervious Concrete has water to cement ratio restrictions that are so low as stated in the literature review. Pervious Concrete is zero slump concrete. Thus, to assess its workability the balling method was used see Figure 10.

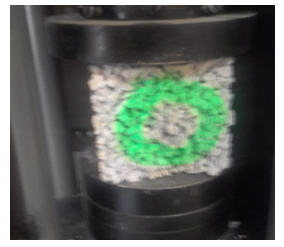

2.18. Compressive test

Compressive strength test of hardened concrete was done in accordance with Standard SANS 5861- 3-2006, The compressive strength test was performed for 7 days and 28 days.

2.19. Void content

Voids Ratio, quite simply put, is the ratio between voids (or empty spaces) to the volume of solid concrete mass. The void content of Pervious Concrete is crucial as it directly affects permeability as well as compressive strength. To determine the total volume in the specimen was calculated as follows:

2.20. Analysis Approach

To ensure reliability and integrity of results, the experiments were carried out at SGS Matrolab, which is an independent SANAS accredited commercial laboratory located at Borksburg. The results were then compared to:

- Roads Assert Classification (TRH 26)

- Technical Design Specification (COTO)

There is currently no technical specification for Pervious Concrete. The current South African pavement design manuals were developed for conventional solid concrete, and not for pervious concrete. To this effect, all the material performance data, material behavior and algorithm modelling, were developed for conventional concrete, and not for any other “Green Solutions” such as Pervious Concrete. This critical limitation in research and development, particularly in South Africa requires that we rely on International Best Practice Research Guidelines. These guidelines place compressive strength criteria in determining which concrete class is applicable for which areas of pavement. The guidelines are derived from global research papers, which adopts the following synthesis in terms of International Best Practice:

- Sidewalks: 7 – 15Mpa

- Drainage Layers: 7 – 15Mpa

- Car Parks: 10 – 15Mpa

- Low Traffic Roads: 25 – 30Mpa

The above practice guidelines were used in this research in determining the suitability of the derived pervious concrete mix in one of the above pavement structures.

The experimentation was phased out in the following phases:

- Phase I: A trial mix experiment to determine the appropriate aggregate size.

- Phase II: Determine the influence of compacting Pervious Concrete.

- Phase III: Investigate Pervious Concrete strength enhancing materials (Fine aggregates, Rubber, Fly Ash, and Steel Fibers)

- Phase IV: Formulated a combination mix involving the best performing materials from Phase III

The material used to enhance the compressive strength of the Pervious Concrete in this study were based on the literature with the following parameters being kept constant according to the studies namely:

- In accordance to studies by [6; 29; 33] and Table 1 and 8, the Aggregates to Cement (A/C) was taken as 4:1.

- Water to Cement ratio (W/C) was taken as 0.32-0.35 as per [10,31,32] and Figure 4. The referenced studies achieved a balance between permeability and compressive strength with that water to cement ratio.

- Minimum acceptable void content was taken as 15% in accordance with the following studies.

- Three coarse aggregates sizes namely 7.1mm; 9.5mm and 19mm were assessed with and without compaction in accordance with [4,10,34] studies. The best performing aggregate best on strength was kept constant throughout the experiment [1,5,35]

- The compaction method was kept constant on all samples that were compaction. Proctor Hammer Compaction Method was used, whereby Layer 1 (Roughly 1/3 of specimen height) was compacted at 15 Blows, Layer 2 (Adding roughly at 2/3 of specimen height) followed by 20 Blows and Layer 3 (Adding roughly at full height of specimen) followed by 25 Blows, in each instant applying a consistent weight of 2.5 Kilograms as per MOD AASHTO Compaction specification.

Strength optimization

Fly Ash, Fine aggregates, Rubber Crumbs, and Steel Fibers were material chosen for the study to enhance Pervious Concrete compressive strength; the range of determination was based on literature findings as stated below:

- Fly ash mix was added to the control mix 2% to 8% was in substitution of the proportioned cement weight.

- Fine aggregates mix was added to the control mix 0% to 7% was in substitution of the proportioned coarse aggregate weight.

- Waste tyre rubber was added to the control mix 0% to 7% was in substitution of the proportioned coarse aggregate weight (2,5 % to 10%) [8]

- Stainless steel was added to the control mix 0% to 7% was in substitution of the proportioned coarse aggregate weight (1% – 2%) [22,28].

With the best performing quantity from each additional material combination trial mix was developed create a Trial mix of (fly ash + Fine aggregates + Rubber) and (fly ash + Fine aggregates + Rubber+ Steel fiber) mixes. Table 10 indicates the mix design of the samples.

3. Results

3.1. Aggregates Properties

Aggregates properties of the dolomite rock coarse aggregates (7.1mm, 9.5mm and 19mm), river fine aggregates (fine aggregate) were determined, and aggregate grading analyzed. Table 9 below shows the aggregates properties of the aggregates used.

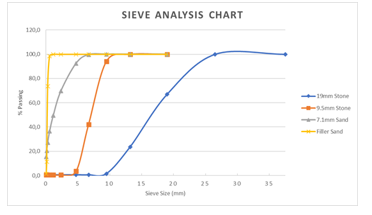

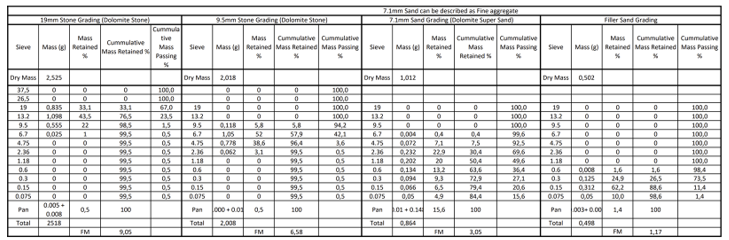

Fine and coarse aggregates were used, and a grading analysis was determined, material was sieved to determine the proportion using the standard sieve sizes. Figure 19 and Table 11 indicates good grading as it shows more than 90% passed a 4.75µm sieve and only between 5 and 25% passed thru a 150-µm sieve.

The fine aggregates were in accordance to SANS 1083: 2006 standard at 20% and coarse aggregates at 10% level. According to SANS 1083:2017, the acceptable FM lower limit is 1.2 and as presented below was acceptable which was important for particle size distribution of concrete fine aggregates. According to (Concrete-Institute, 2009) fine aggregates grading has major impact on workability, cohesiveness, and bleeding of fresh concrete.

Table 9 Aggregates Properties

Figure 19 Sieve Analysis Chart

3.2. Phase I Results

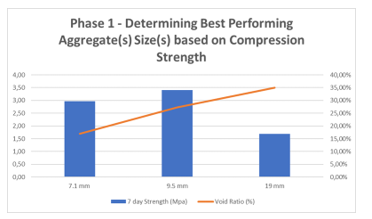

Phase I determined aggregate size suitable to enhance and improve Pervious Concrete compressive strength and assess the behavior of dolomite rock aggregates of the chosen sizes. Aggregate size used (7.1mm, 9,5mm and 19mm). Figure 20 below presents compressive strength in the absence of compaction.

Figure 20 Determining best performing aggregate size(s), 0% Compaction.

Above Figure 20 indicates the relationship between the void content and compressive strength, that the smaller the coarse aggregate size the smaller the void space and the higher the

Table 10 Mix Design

Table 11 Sieve Analysis

compressive strength and 7.1mm, 9.5mm and 19mm aggregate size were proof with 2.97MPa, 3.4MPa, 1.7MPa respectively in 7 days. The results of 9.5mm aggregates highest strength within acceptable void content was consistent with literature. Smaller aggregate sizes (7.1mm and 9.5mm) yielded better compressive strength results when compared to the 19mm stone sizes, reason being the smaller aggregates have a larger number of contact points (cement fillets) per unit volume. In addition, these results correlate with reduced voids content, reconciling findings by other researchers in literature section.

3.3. Phase II Results

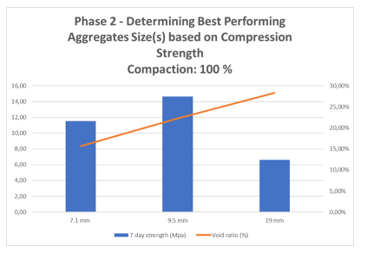

Phase II determined the influence of compaction on the chosen three aggregate sizes. The aim of this experiment was to determine the effect of compaction on compressive strength and the void content of Pervious Concrete. A trial mix experiment was carried out to establish the best performing aggregate size between the 7.1mm, 9.5mm and 19mm when compaction was included in all samples.

Figure 21 Determining best performing aggregate size(s), 100% Compaction.

The results in Figure 21 indicated an increase in strength parameter, particularly on the 9.5mm aggregate stone from 3.4MPa to 14.63MPa with void content of 27,26% uncompacted to 22,28% compacted. This indicates compaction effort creates an improved interlocking of aggregates, leading to improved cohesion properties and compression strength. The resultant Voids Content (%) is at 22,28%, sitting comfortably in the range of an acceptable Voids Content of 15 – 30%, as per published research mentioned in chapter 2.

3.4. Phase III Results

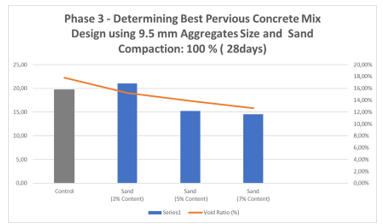

- Fine Aggregates

An experiment was carried out with only fine aggregates inclusion in varying quantities to determine exactly the quantity required to enhance a dolomitic rock Pervious Concrete. The fine aggregate mix contained 9.5mm stone aggregates and river fine aggregates, at a water/cement (W/C) ratio of 0.30 – 0.35 range, as per published research for Pervious Concrete. A total of 24 samples of Fine Aggregate Mix were mixed, with varying volumetric contents (0%, 2%, 5% and 7%) of River Fine aggregatess. Figure 22 below presents the 28days compressive strength results and void content.

Figure 22 Fine aggregates Aggregate Mix (9.5mm Stone and River Fine aggregates Variations)

Partial inclusion of fine aggregates did increase compressive strength of Pervious Concrete from 14.6MPa without fine aggregates to 16.8MPa with 2% of river fine aggregates inclusion in 7 days and 19.7MPa to 21.5MPa respectively in 28day results, by including fine aggregates increases the amount of mortar which increases the contact area between aggregates, previous studies mentioned in chapter concurs with research findings.

The improvement in strength was also attributed to void reduction as discussed in Phase II that void content reduction results in increase compressive strength in Pervious Concrete. Another contributor to compressive strength increase was particle distribution, by adding fine aggregates it increased the surface area which improved bonding. Pervious Concrete comprises of large aggregates with limited fines, adding fine aggregates fills up the void spaces and fine aggregates blends with the cement paste which resulted in a well graded and interlocking mix. Figure 22 shows a decrease in compressive strength beyond 2%. At 5% partial fine aggregates compressive strength was 15.2MPa and 14.5MPa with 7% fine aggregates.

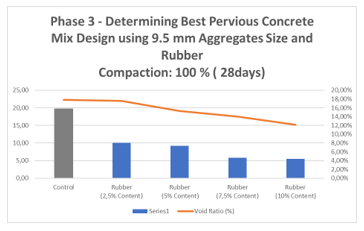

- Waste Rubber

A combination of 9.5mm aggregates and Rubber Crumbs were mixed, with varying volumetric contents (2.5%, 5%, 7.5% and 10%) of River Fine aggregates. Figure 23 represents the results.

Figure 23 Fine aggregates Aggregate Mix (9.5mm Stone and Rubber Crumbs Variations).

Rubber crumbs are larger in size compared to fine aggregates and have irregular shapes which resulted with a mix that was not well graded, this resulted in unsatisfactory compressive strength results. The rubber crumbs affected the bonding between the coarse aggregates and the cement paste, compared to fine aggregates and coarse aggregates rubber has less stiffness by adding rubber crumbs to the Pervious Concrete mix reduces its stiffness therefore affecting it compressive strength. Evidently from the above results, an increase in rubber content in Pervious Concrete decreases compression strength. Scientifically, this makes sense as the higher the elasticity between the interlocking interface of aggregates, the lower the cohesion properties, leading to reduced compression strength. With concrete being classified as rigid pavement and granular materials being classified as flexible pavements, adding flexibility or elasticity to traditional classified rigid pavement (concrete), is a scientific contradiction in pavement design methodology. Elasticity thereof, speaks to flexibility in pavement concrete, and could possibly lead to further research in the development of flexible pavements using Pervious Concrete.

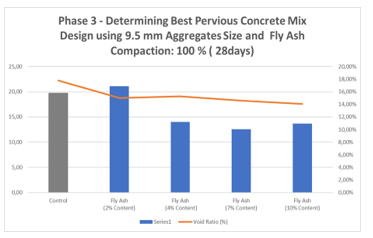

- Fly Ash

Combination of 9.5mm aggregates and Fly Ash were mixed, with varying volumetric contents (2%, 4%, 8% and 10%) of River Fine aggregatess. Figure 24 presents the 28days compressive strength results and the void contents.

Figure 24 Cementitious Aggregate Mix (9.5 mm Stone and Fly Ash Variations)

Partially replacing cement with fly ash resulted in less water requirement and improved workability of the Pervious Concrete. The reduction in water led to a decrease in interconnectivity. Figure 24 results illustrated an increase in compressive strength when 2% of fly ash was included. Fly ash improving Pervious Concrete was a bonus due to cement cost hikes, though it was small quantities in the experiment batch, in road construction 2% will be a great cost saving. Pervious Concrete on its own was 19,69MPa in 28day when Fly Ash was included it slightly increased to 21.70MPa in 28 days. Beyond 2% a serious decline in compressive strength was noticed which didn’t make sense. [36] discovered that the more fly ash added on the mix lowered compressive strength.

- Steel Mix

This experiment was to determine the effect of steel on material strength performance. Figure 25 below are the results of using steel fiber to enhance Pervious Concrete compressive strength, with 19MPa at 7 Days curing strength expected of 29MPa after 28 Days of curing however that was not the case. Following the 28 Day strength, the 1% and 2% steel fibre reinforced concrete, has practically yield similar results, roughly at 23MPa compressive strength. This strength also represents a distorted concrete strength curve, with results somewhat lower than traditional solid concrete in strength yield, representing 74% concrete strength yield than traditional solid concrete, when following traditional concrete strength curve. Though the results indicated promising results for compressive strength its void content compared to the control dropped from 17.81% to 14.79% when 1% steel fiber was included

Figure 25 Fine aggregates Aggregate Mix (9.5mm Stone and Stainless Fiber Variations)

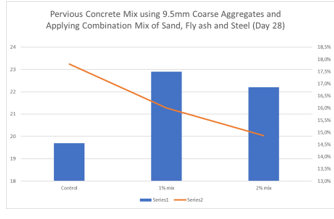

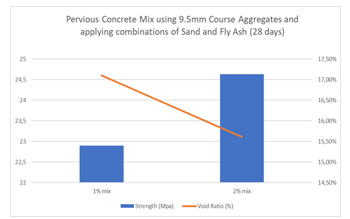

- Strength Optimization

Figure 26 below indicate the results of the highest performing material, fine aggregates and fly ash results were the highest individually, therefore it made sense to combine the two highest strength material when mixed with standard Pervious Concrete. It was by doing so that the highest compressing strength of 25MPa was achieved with an acceptable range of 15,61% of void content.

Figure 26 Pervious Concrete Mix using 9.5 mm Coarse Aggregates and applying combinations of River Fine aggregates, Fly Ash, and Steel 28 Days

4. Conclusion

The following results are based on the 28days compressive strength and void content of different enhancing materials when using dolomitic rock:

- Compaction – Compaction has influence on Pervious Concrete, compressive strength improved though reducing the void content. A 7 day Trial was done with and without compaction which resulted with Non compacted pervious concrete strength of 3.4MPa and 14.6MPa compacted, this affected void content from 27% to 22%.

- Fine Inclusion – Inclusion of fines improved compressive strength; the highest strength was achieved when 2% fine aggregates volume of coarse aggregates as substituted. 28days compressive strength results were 19.7MPa without fines the increased to 21.5MPa with inclusion of fines. The void content was 18% to 15% this resulted from inclusion of both compaction and fines. Beyond 2% substitution compressive strength reduced which could have been associated with the restriction of water and cement.

- Waste Tyre rubber – waste tyre inclusion did not have positive results considering that pervious concrete compacted without any enhancers had the compressive strength of 19.6MPa however with the tyre it yielded 5.8MPa.

- Fly Ash – The following was drawn from fly ash inclusion, the compressive strength slightly increased from 19.7MPa to 21.1MPa, the void content was %18 then 17 % with fly ash inclusion.

- Steel fiber – Steel fiber did enhance pervious concrete compressive strength; this was studied by comparing the compressive strength results of the control specimen and steel fiber specimens. All samples were cured for 7 days and 28 days, the control compressive strength was 20MPa the steel fiber reinforced pervious concrete was 23MPa. The highest compressive strength was achieved when 1% partial replacement of coarse aggregates.

- Combination Mix – Based on the results obtained, best performing materials were combined which were fine aggregates and fly ash. The pervious concrete with a combination of 2% Fly Ash cement replacement and 2% Fine aggregates inclusion gave the highest compressive strength of 25MPa with a corresponding void content of 15%

5. Recommendations

The following recommendation are derived from the current study.

- Prototypes, such as beams and scaled large slabs to determine flexural and or tensile strength, resistance, noise limits and cylinders to determine permeability are necessary.

- The study focused on improving compressive strength whilst remaining within acceptable void content however permeability as well as porosity are recommended.

- To investigate other locally available coarse aggregates, as the dolomite rock didn’t reach the expected but has potential.

- Develop Technical Design Specification for Pervious Concrete in COTO

- Develop Design Criterion for the use of Pervious Concrete (Enforcement) and

- Align COTO Specification to TRH 26 Traffic Class Specification.

- Incorporate Pervious Concrete in the Drainage Manual of South Africa.

- Develop a Labour-Intensive COTO Specification for the Construction of Pervious Concrete, for the South African Context (Skills Development).

- Monitor performance of Pervious Concrete against Traffic and Drainage Demands and develop reliable database for continuous monitoring, research, and development.

6. Acknowledgement

The author wishes to acknowledge Tshwane University of Technology for the support.

- E Martinez, V Valeri, J Hernandez, D Fresno, Proposal of a New Porous Concrete Dosage Methodology for Pavements, 12(19) Materials, 2019. https://doi.org/10.3390%2Fma12193100

- M Offenberg, D Wade, C Weiss. Report on Pervious Concrete. United States of America: American Concrete Institute; 2010, https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/51663557

- A Bonicelli, G Martinez, A. L Guillermo, F. Pumarejo, Improving Pervious Concrete Pavements for Achieving More Sustainable Urban Roads. ScienceDirect, 161, 1568-1573, 2016, https://doi.org/10.1016/j.proeng.2016.08.628

- F Yu, D Sun, & Hu. Study on the pores characteristics and permeability simulation of pervious concrete based on 2D/3D CT images. Construction and Building Materials, 200, 687-702, 2019, https://doi.org/10.1016/j.conbuildmat.2018.12.135

- M Seslija, J. D Radovic,. & D Kukaras, Possibilities of Pervious Concrete Application in Road Construction. International Standard, 2017. http://dx.doi.org/10.17559/TV-20160524162507

- P. D Tennis, M. L Leming, & D. J Akers, Pervious Concrete Pavements, Technical Report, Portland Cement Associates, 2004, https://www.researchgate.net/publication/242722509

- N. Jin, 2010. Fly Ash Applicability in Pervious Concrete, The Ohio State University. https://doi.org/10.1016/j.cscm.2021.e00502

- M Gesoglu, E Guneyisi, G Khoshnaw, S Ipek. Investigating properties of pervious concretes containing waste tire rubbers. Construction and Building Materials, 73, 19-24, 2014. https://doi.org/10.1016/j.conbuildmat.2014.12.073

- Y. J. Kim, A. Gaddafi, I. Yoshitake. Permeable concrete mixed with various admixtures. Materials and Designs, 100, 110-119, 2016, https://doi.org/10.1016/j.matdes.2016.03.109

- T Joshi, Evaluation of mechanical properties of previous concrete with changing cement content. Research Gate, pp. 2-7, 2016, http://dx.doi.org/10.1201/b20013-9

- K Cosic., L Korat, V Ducman, I. Netinger, Influence of aggregate type and size on properties of pervious concrete. Construction Building Material, 78, 69-79, 2014. https://doi.org/10.1016/j.conbuildmat.2014.12.073

- K. S Elango, & V Revathi, G Fal_ Binder Pervious Concrete. Construction and Building Materials, 140, 91-99, 2017. https://doi.org/10.1016/j.conbuildmat.2017.02.086

- A. K. Chandrappa, K. P. Biligiri, Pervious Concrete as a Sustainable Pavement Material- Resesrch Findings and Future Prospects: A state-of- the-art review. Construction and Building Materials, 111, 262-274, 2016. http://dx.doi.org/10.1016/j.conbuildmat.2016.02.054

- C Lian, & Y Zhunge, Optimum mix design of enhanced permeable concrete – An experimental investigation. Construction and Building Materials, 24, 2664-2671, 2009, https://doi.org/10.1016/j.conbuildmat.2010.04.057.

- A. Azada, S. F Mousavi, H. Karami, S. Farzin. Using Waste Vermiculite and Dolomite as Eco Friendly Additives for Improving the Performance of Porous Concrete. Engineering Journal, 22(5), 2018. http://dx.doi.org/10.4186/ej.2018.22.5.87.

- Department of Public Works, appropriate development of infrastructure on dolomite guidelines for consultants, South Africa. 2003.

- B Haung, H Wu, X Shu, G Burdette, Laboratory evaluation of permeability and strength of polymer- modified pervious concrete. Construction and Building Materials, 24, 818-823, 2010. https://doi.org/10.1016/j.conbuildmat.2009.10.025.

- J Yang, & G Jiang, Experimental study on properties of pervious concrete pavement materials. Cement and Concrete Research, 33, 381-386, 2003, https://doi.org/10.1016/S0008-8846(02)00966-3.

- Y Aoki, R. S Ravindrarajah, H Khabbaz, Properties of pervious concrete. Road Materials and Pavement Design, 2012, doi:10.1080/14680629.2011.651834

- H Wang, Investigation on the mechanical properties and environmental impacts of pervious concrete containing fly ash based cement aggregate. Construction and building materials, 202 387-395, 2019. http://dx.doi.org/10.1016/j.conbuildmat.2019.01.044

- B. Han, X. Yu, J. Ou. Self-Sensing Concrete in Smart Structures, 2014, https://doi.org/10.1016/C2013-0-14456-X.

- K. H. Tan, E. Lim, T. F. Fwa, 2015. Steel fiber-reinforced pervious concrete for urban roads, Nepal: Civil Engineering, National University of Singapore. tankh@nus.edu.sg.

- Lin, W. & Yoda, T., 2017. Bridge Engineering Classification, Design Loading, and Analysis Methods, 2017, https://www.researchgate.net/publication/328019943_Bridge_engineering_Classifications_design_loading_and_analysis_methods.

- Channappa: Reddy, P. K. Experimantal Study On Steel Fiber-Reinforced Pervious Concrete, 6(8), 441-447, 2019, International Research Journal of Engineering and Technology (IRJET).

- Lee, M. et al., Mechanical Properties of High-Strength Pervious Concrete with Steel Fiber or Glass Fiber. MDPI, 1-18 2022. http://dx.doi.org/10.3390/buildings12050620.

- C Ng, et al. Properties of Modified High Permeable Concrete with a Crumb Rubber. The Open Civil Engineering Journal, 2019. http://dx.doi.org/10.2174/1874149501913010082

- J. Farnoosh, M. Khorram, G. Karimi, & N Hataf, Experimental investigation of mechanical properties of crumbed rubber concrete containing natural zeolite. Construction and Building Materials, 208, 651-658, 2019. http://dx.doi.org/10.1016/j.conbuildmat.2019.03.063

- K Chandramouli, S, N Chaitanya, A, M Mrunalini, G Hymavathi, Experimental studies on pervious concrete by using waste tires rubber as partial replacement of coarse aggregate, Chandramouli, K. et al., n.d. Experimental studies on pervious concrete by using waste tires rubber as partial replacement of coarse aggregate. | ISSN: 2456-3315,2022, http://www.ijrti.org/.

- D. P. M Tripathi, S.M. Ashraf Hussain, P. Madhav. An Experimental Study on Pervious Concrete (Mix-Ratio, Strength and Porous Properties). International Journal of Engineering Research & Technology (IJERT), 6(12), 2017, DOI:10.17577/IJERTV6IS120054

- K Alalea, H. S. Wong, C. R Cheeseman. Clogging in permeable concrete: A review. Journal of Environmental Management, 2017 193 221-223, http://dx.doi.org/10.1016/j.jenvman.2017.02.018

- Y. Joung, Z. Grasley, Evaluation and Optimization of Durable Pervious Concrete for Use in Urban Areas, Southwest Region University Transportation Center (U.S.), 2008,

https://rosap.ntl.bts.gov/view/dot/16416/dot_16416_DS1.pdf - T. Mulyono, Anisha, 2019. Properties of pervious concrete with various types and sizes of aggregate, 276, 2019, https://doi.org/10.1051/matecconf/201927601025.

- T. Ahmed, S. Hoque, Study on pervious concrete pavement mix designs. 476(2020) 2020, http://dx.doi.org/10.1088/1755-1315/476/1/012062

- A. E. El-Maaty, Establishing a Balance Between Mechanical and Durability Properties of Pervious Concrete Pavement. American Journal of Traffic and Transportation Engineering, 13-15. 2016, http://dx.doi.org/10.11648/j.ajtte.20160102.11

- D Ramadhan, F Muslim, & L Sagita, Mechanical properties of porous concrete and design recommendation for low traffic road pavement in Indonesia. 794(2021), 2021, DOI 10.1088/1755-1315/794/1/012003

- Sudhir Kumar Boddu, Investigating the Effect of Aggregate Size and Binder Material Proportion on Strength and Permeability of Pervious Concrete by Statistical Modeling. Springer Nature Singapore. 2022, http://dx.doi.org/10.1007/978-981-19-2273-2_16

No. of Downloads Per Month

No. of Downloads Per Country