Application of Lean Practices in Food Supply Chain: The Case of Morocco

Volume 8, Issue 4, Page No 101-110, 2023

Author’s Name: Fadwa Bouhannanaa), Akram El Korchi

View Affiliations

Systems engineering laboratory and decision support, National School of Applied Sciences, Ibn Zohr University, Agadir, Morocco

a)whom correspondence should be addressed. E-mail: fadwabouhannana@gmail.com

Adv. Sci. Technol. Eng. Syst. J. 8(4), 101-110 (2023); ![]() DOI: 10.25046/aj080412

DOI: 10.25046/aj080412

Keywords: Lean manufacturing, Practices, Food Supply chain, Performance, Measure

Export Citations

Recent studies show the benefits of lean manufacturing implementation in agri-food industries to improve operational and environmental performance. However, only a restricted number of studies have addressed the implementation of lean practices in food companies located in developing countries. This study aims to assess the current implementation status of lean practices in Moroccan agri-food companies, particularly small and medium-sized enterprises, and to examine their impact on operational and environmental performance. Responses from 45 agri-food companies were collected through a questionnaire. The results show that the degree of implementation of lean practices in the Moroccan food industry is generally average. On the other hand, some lean practices are implemented more frequently compared to others., e.g. customer involvement, employee involvement, supplier involvement and total productive maintenance are the most implemented. On the other hand, pull and setup are not used very much. The findings also demonstrate the positive impact of lean practices on both operational and environmental performance.

Received: 10 April 2023, Accepted: 11 July 2023, Published Online: 26 August 2023

1. Introduction

The term “lean” was initially coined in 1988 by [1] to characterize the Toyota production system. Subsequently, in 1990, [2] defined lean manufacturing as a system that achieves equivalent outputs while utilizing fewer inputs, resulting in increased value for the end-user. This particular definition highlights the importance of waste identification and elimination [3]. Empirical studies have consistently demonstrated that lean manufacturing has positive impacts on productivity, quality, and both customer and employee satisfaction [4], [5].

Numerous studies in the literature have demonstrated the advantages of lean implementation, which can take the form of quantitative improvements, like production cycle time, inventory, defects, and waste, or qualitative benefits like customer satisfaction, good communication, and job satisfaction [6]. These findings are consistent with previous research by [7] and [8], which established a positive association between lean implementation and operational performance. Additional studies, conducted by [9] and [10], have also provided evidence of the advantages of lean implementation on operational performance. The literature suggests that lean implementation not only leads to improved operational performance [9], [10], but also helps companies achieve their environmental objectives [11].

Numerous studies have explored the suitability of implementing lean manufacturing in the food industry. [12], [13], while others have chosen to ignore the agri-food sector due to the challenges related to the seasonal variability and storages issues [14].

Various studies have been conducted on lean implementation in agri-food companies of developed countries, whereas, few research has focused on the context of developing countries. This study aims to bridge this gap by examining the extent of lean practice implementation in agri-food companies in a developing country, such as Morocco. It also examines the effects of lean practices on the operational and environmental performance of these companies. The primary objective is to assess the current status of lean practices in Moroccan agri-food companies, particularly small and medium-sized enterprises, and evaluate their impact on operational and environmental performance. Responses from 45 agri-food companies were collected through a questionnaire. This study addresses the effect of control variables such as firm size [15]–[17], location and the existence of the lean project. Finally, according to the author’s knowledge, this study is the first attempt assessing the impact of lean practices on operational and environmental performance in Moroccan agribusiness and analyze the present status of implementation of lean manufacturing practices among food Moroccan agri-food companies (small and medium-sized). Except for [18], who explored an empirical study in Moroccan agri-food firms to determine the principles of lean adopted by these firms. What makes this study limited is the fact that they chose a sample of only nine companies.

The study endeavors to provide answers to the following two research questions:

- To what extent are lean practices implemented in agri-food companies in Morocco?

- What is the influence of lean practices implementation on operational and environmental performance?

The paper follows the following structure: Section 2 provides a comprehensive literature review. Section 3 outlines the conceptual framework utilized in the study. The research methodology is detailed in Section 4. The study’s findings are summarized in Section 4. The implications of these results are discussed in Section 5, and the paper concludes with final conclusions in the last section.

2. Theoretical background

2.1. Lean manufacturing

The success initially attained by Toyota, followed by various organizations worldwide, has prompted numerous companies to embark on lean projects [19]. Presently, lean has gained popularity not only in developed countries but also in select developing nations [20], [21]. However, each organization implements lean practices based on its unique circumstances, making it impossible to follow a single, standardized recipe for guaranteed success [22].

Lean manufacturing is a business philosophy that focuses on optimizing customer value while minimizing waste across various areas of operation. This includes addressing issues such as overproduction, waiting time, defects, overprocessing, excess inventory, unnecessary motion, and underutilized talent. In the agri-food sector, Lean principles have been applied to various aspects of food production, from farm to table. A study conducted by [23] that found that Lean principles can be applied effectively in the agri-food sector to improve processes such as supply chain management, production planning, and process flow. In [24], the author summarized into different principles: defining value, defining the value chain, flow and standardization.

Studies have consistently demonstrated that the adoption of Lean principles yields favorable outcomes in terms of both operational and environmental performance. In [23], the author found that Lean principles can improve supply chain management, production planning, and process flow, leading to increased efficiency and reduced waste in the agri-food sector. Another study by [13] found that Lean implementation can help agri-food businesses reduce costs and improve quality, leading to increased competitiveness.

Numerous studies have provided robust evidence indicating that Lean practices have a significant and positive impact on multiple dimensions of operational performance [24], [25].

Several studies have identified and adopted five key operational performance indicators as outlined [12], [15]. These indicators encompass reduced inventory [26], improved quality [26], [27], increased productivity [3], [28], shortened cycle time [28], [29], and enhanced delivery time [30], [31]. In addition, the adoption of Lean principles can indeed contribute to improved environmental performance, given its emphasis on waste reduction and minimizing negative environmental impacts. A study conducted by [32] investigated the influence of the five core Lean methods on four environmental performance measures. (material utilization, energy consumption, non-product outputs, and pollutants released). They found that TPM and JAT had a significant impact on environmental performance. However, continuous improvement only had an effect on material utilization. In [33], the author found that Lean implementation in the meat processing industry reduced waste and improved production efficiency, leading to reduced energy use and decreased greenhouse gas emissions. These findings suggest that Lean implementation can have a positive impact on both operational and environmental performance in a variety of industries.

2.2. Implementing lean practices in the agri-food companies

The agri-food industry holds a vital position within the Moroccan economy [18], [34]. The agri-food industry, recognized as a significant pillar of the national economy [35], is distinguished by its diverse agricultural activities, expanding export markets, and potential for sustainable development. Despite the important position of this sector, most companies face several challenges: operational, financial, commercial, and technological [18]. The agri-food industry necessitates a multifaceted production process, dealing with a diverse range of products characterized by varying levels of perishability. This industry also faces challenges associated with production time variations and the need to meet diverse customer demands.

Current literature emphasizes the significance of implementing lean manufacturing practices in the food industry as a means to improve operational efficiencies [36]–[39]. However, the implementation of lean practices in the agri-food sector presents unique challenges, primarily due to seasonal variations, large-scale production, processing complexities, and issues related to storage. It is important to recognize that lean principles and tools, initially developed for mass production of non-perishable goods, may not have universal applicability across all industries, including the food industry [40].

Numerous studies have explored the adaptability of lean manufacturing principles in the context of the food industry [12], [13]. However, some studies have overlooked the agri-food sector due to its unique challenges associated with seasonal variability and storage issues [41]. Nevertheless, research conducted by [10] and [42] has demonstrated the substantial benefits that lean manufacturing can bring to the food industry. Again, lean can help agri-food companies reduce non-value-added time, reduce waste, and increase the percentage of operational value-added activities [10], [42].

Over the years, there has been a noticeable surge in research focusing on lean practices within the agri-food industry. This increasing trend can be attributed to the growing recognition of the importance of waste reduction and the expanding population within the agri-food supply chain [43], [44]. However, limited research has provided tangible evidence of the actual impact resulting from the implementation of lean practices [45] with few exceptions such as output projections derived from modeling-based [46]. Most studies in this domain have predominantly relied on case studies, action research, or perception-based impact evaluations, which possess limited generalizability in assessing the effects [38]. According to [47], a significant proportion of studies conducted in the food industry are based on case studies, with only a limited number relying on empirical surveys [48]. Consequently, the results pertaining to the application of lean manufacturing in the food sector remain somewhat contentious. In [49], the author demonstrated how the VSM technique can be applied to Finnish food plants. In a study conducted by [50], a case study approach was employed to examine medium-sized cookie companies. The results indicated that the application of lean techniques such as 5S, kaizen, changeover, and TPM (Total Productive Maintenance) led to improvements in equipment availability, reduction in material waste, and enhancements in overall product quality.

The objective of this research is to assess the level of implementation of lean practices in agri-food companies within developing countries, with a specific focus on Moroccan companies. The study uses a conceptual model of lean manufacturing by [3] that covers both internal and external practices. The ten key components of lean manufacturing identified by Shah and Ward cover supplier engagement, customer involvement, and internal company issues. Operational performance is measured using [48], while environmental performance is assessed using various sources, including [51]–[55].

3. Development of the conceptual model

Scholarly journals have recently published many articles on the impacts of lean practices on operational and environmental performance. The literature review identifies commonly associated practices between lean practices and performance metrics. The lean conceptual model, presented in Table 1, is based on this review and divided into three levels: concepts, strategies, and practices. The model incorporates sections from different literature models and studies.

4. Methodology

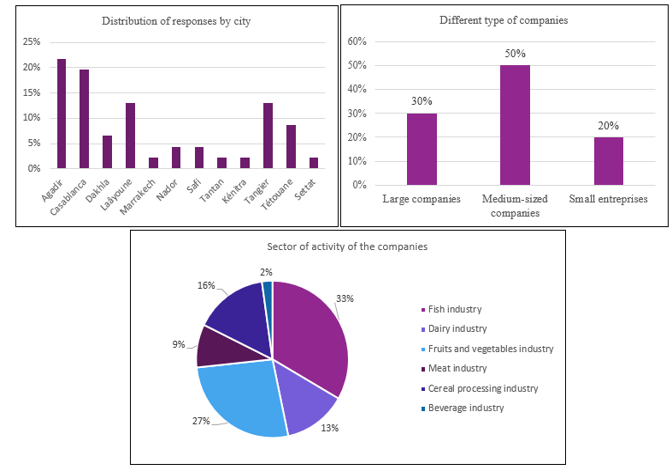

This study was conducted in Morocco, within agri-food companies. The sectors of activity chosen in this study are canned goods: fish, capers, jams, olives, and tomatoes. A questionnaire was designed to measure the implementation of lean practices and their impact on operational and environmental performance. Prior to its administration, the questionnaire underwent testing and validation by three managers and two academics to ensure its reliability and validity. The questionnaire has five sections. The first section is reserved for general information about the company. The second section concerns the implementation of lean practice. The third section is used to extract the respondents’ perceptions regarding implementing these practices on performance. A manager in the Ministry of Industry was contacted to obtain the database of Moroccan companies.

A total of 230 companies operating in the agri-food sector received the questionnaire for participation in the study. A total of 45 respondents answered the questionnaire.

The Likert scale that was adopted in this questionnaire had 5 points. The companies were requested to indicate the extent of lean practice implementation within their respective organizations. (1= Not implemented, 5= Strongly implemented).

5. Results

5.1. Descriptive analysis

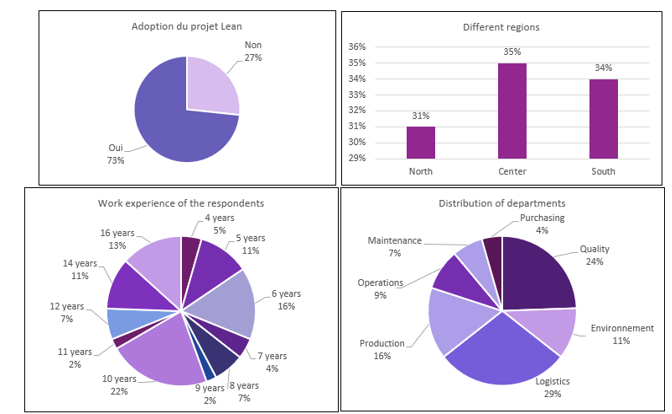

In this study, 45 Moroccan companies participated, with 72% confirming the implementation of a lean project in their respective companies, while 28% reported not having a lean project. The majority of the participating companies were small and medium-sized enterprises (70%), with the fish industry representing 33% and the fruits and vegetables industry representing 27% of the sectors. The companies’ distribution across regions was relatively equal, with 31% from the north, 34% from the center, and 35% from the south regions (Figure 1). Regarding the work experience of the respondents, notable percentages include 22% with 10 years of experience, 16% with 6 years of experience, and 13% with 16 years of experience. Figure 1 demonstrates that Logistics with 29%, Quality with 24%, and Production with 16% were the three departments that significantly participated in the study.

5.2. Implementation level of lean practices

In response to the initial inquiry, a descriptive analysis was performed to evaluate the extent of adoption of all Lean practices (as presented in Table 2).

The results show that the implementation of Lean practices in Moroccan agri-food firms is relatively moderate, with an average score of 3.15. Nevertheless, the questionnaire data reveals a considerable variation in the implementation level of each practice. Specifically, practices associated with preventive maintenance, employees, customers, suppliers, and flow are highly implemented in Moroccan agri-food companies, while practices belonging to the categories of Pull, Setup, and SPC are less widely adopted.

Three non-parametric tests were administered to examine if there were any differences in the responses and to assess the scores of each variable outlined in Table 3. The initial test utilized in this study was the Friedman test, which aimed to assess the perceived differences in the levels of implementation of lean practices. The findings indicate that there is a noteworthy distinction in the level of implementation of certain practices : Pull, supplier involvement, setup and TPM, as depicted in Table 2, with p-values less than 0.05.

Figure 1: Descriptive analysis

Table 1: Conceptual model for lean implementation

| Concepts | Strategies | Pratiques | References |

| Lean | Waste reduction | 5S | [57], [58] |

| Reduction in the size of product batches | |||

| Reduction of excess inventory | |||

| Reducing scrap rate | |||

| Layout of the workshop in order to optimize the process sequences | |||

| Balancing of production lines | Balancing of production lines | [57], [58] | |

| Stabilization of the rate of production machines | |||

| Elimination of bottlenecks | |||

| Synchronization of the production line rhythm according to customer demand | |||

| Pull | Pull production system | [48], [58], [59] | |

| Use of the Kanban | |||

| Production at one station is governed by the demand emanating from the subsequent station. | |||

| Flow | The products are categorized into families based on their similar processing requirements | [48], [58], [59] | |

| The factory layout is determined by the product families. | |||

| Setup | Reduced changeover time | [58], [59] | |

| The production cycle time is closely monitored to ensure a swift response to customer requests | |||

| Use of techniques such as SMED (Single Minute Exchange of Die(s)) to reduce changeover time | |||

| SPC | SPC (Statistical Process Control) | [57], [58] | |

| Ishikawa diagram | |||

| Use of visual tools (Control charts…) | |||

| Statistical techniques to reduce variance in processes | |||

| Process capability analysis prior to product launch | |||

| Total Preventive Maintenance | Preventive maintenance plan |

[48], [58], [59] |

|

| Time is set aside each day to plan activities related to equipment maintenance | |||

| Equipment maintenance checklists are posted regularly in our workshops | |||

| Employee involvement | Workshop employees are trained to perform several functions | [48], [58], [59] | |

| Workshop employees play a crucial role in problem-solving teams. | |||

| Shop floor employees participate in process and product improvement efforts | |||

| Supplier involvement | We maintain regular and close contact with our suppliers. | [58], [59] | |

| Our primary suppliers follow a just-in-time delivery approach, providing goods to the factory as needed. | |||

| We are proactively working to minimize the number of suppliers in each category. | |||

| Customer Involvement | Our customers provide us with feedback regarding the quality and delivery performance of our products. | [58], [59] | |

| We deliver to our major customers just-in-time | |||

| Our customers frequently share market demand with our sales department | |||

| Our customers are directly engaged in shaping our product offerings. | |||

| Performance | Operational performance | Reduction of the production cycle time | [48] |

| Reduction in delivery time | |||

| Increasing productivity | |||

| Reduction of customer complaints | |||

| Production cost reduction | |||

| Product Quality Improvement | |||

| Scrap Rate Reduction | |||

| Environmental performance | Reducing of consumption of hazardous/toxic materials | [52] | |

| Minimization of air emissions. | [51]–[53], [55] | ||

| Minimization of water consumption | [51]–[53], [55] | ||

| Minimization of solid waste | [52] | ||

| Reduction of environmental accidents | [52], [55] | ||

| Reducing CO2 emissions from transportation | [55] | ||

| Decrease of cost for energy consumption | [52] | ||

| Decrease food wastes | [54] |

Table 2: Implementation of lean practices in Moroccan agri-food companies

| Abbreviation | Section | Practices | Mean |

| S1 | Waste reduction | 5S | 2.96 |

| Reduction in the size of product batches | 3.07 | ||

| Reduction of excess inventory | 3.14 | ||

| Reducing scrap rate | 3.25 | ||

| Layout of the workshop in order to optimize the process sequences | 3.11 | ||

| S2 | Balancing of production lines | Balancing of production lines | 3.46 |

| Stabilization of the rate of production machines | 3.29 | ||

| Elimination of bottlenecks | 3.11 | ||

| Synchronization of the production line rhythm according to customer demand | 3.43 | ||

| S3 | Pull | Pull production system | 2.96 |

| Use of the Kanban | 2 | ||

| Production at one station is governed by the demand emanating from the subsequent station. | 2.89 | ||

| S4 | Flow | The products are categorized into families based on their similar processing requirements | 3.54 |

| The factory layout is determined by the product families. | 3.07 | ||

| S5 | Setup | Reduced changeover time | 2.68 |

| The production cycle time is closely monitored to ensure a swift response to customer requests. | 3.32 | ||

| Use of techniques such as SMED (Single Minute Exchange of Die(s)) to reduce changeover time | 2.21 | ||

| S6 | SPC | SPC (Statistical Process Control) | 2.54 |

| Ishikawa diagram | 2.93 | ||

| Use of visual tools (Control charts…) | 2.68 | ||

| Statistical techniques to reduce variance in processes | 2.68 | ||

| Process capability analysis prior to product launch | 3.21 | ||

| S7 | Total Preventive Maintenance | Preventive maintenance plan | 3.57 |

| Time is set aside each day to plan activities related to equipment maintenance | 3.32 | ||

| Equipment maintenance checklists are posted regularly in our workshops | 3.14 | ||

| S8 | Employee involvement | Workshop employees are trained to perform several functions | 3.54 |

| Workshop employees play a crucial role in problem-solving teams | 3.46 | ||

| Shop floor employees participate in process and product improvement efforts | 3.25 | ||

| S9 | Supplier involvement | We are frequently in close contact with our suppliers | 4 |

| Our primary suppliers follow a just-in-time delivery approach, providing goods to the factory as needed. | 3.39 | ||

| We are proactively working to minimize the number of suppliers in each category | 2.68 | ||

| S10 | Customer involvement | Our customers provide us with feedback regarding the quality and delivery performance of our products. | 3.71 |

| We deliver to our major customers just-in-time | 3.75 | ||

| Our customers frequently share market demand with our sales department | 3.57 | ||

| Our customers are directly engaged in shaping our product offerings. | 3.5 |

Wilcoxon test is a second test which aimed to compare the levels of utilization of diverse lean practices. The results suggest that there is a considerable contrast among the lean practices linked to Pull, statistical process control, Flow, Setup, and supplier involvement. However, there is no substantial variation observed in the other practices, with p-values greater than 0.05.

As part of this study, an inferential analysis was carried out to investigate the relationship between the control variables (presence of a lean project and company size) and the execution of lean practices in agri-food enterprises. The Kruskal-Wallis test indicate that a significant contrast exists between the companies that have a lean project and those that do not, in terms of the practices related to Pull, employee involvement, and TPM with p-values less than 0.05. However, the analysis did not find any significant difference in the degree of implementation of lean practices between small and mid-size companies. The p-values obtained were greater than 0.05, indicating that the observed differences were not statistically significant.

5.3. Impact of lean practices on performance

To address the second research question, survey participants were asked to rate the impact of implementing lean practices on both operational performance (e.g., reduction in delivery time, increased productivity, reduction in production cycle time) and environmental performance (e.g., reduced water consumption, food waste reduction, solid waste reduction) using a Likert scale ranging from 1 to 5. In this scale, 1 indicated no effect, 2 represented a minor effect, 3 denoted a neutral response, 4 indicated a moderate effect, and 5 signified a major effect. The results of this analysis can be found in Table 4 and reveal that the implementation of lean practices significantly affects several aspects of operational performance, such as reducing production costs, enhancing product quality, and increasing productivity. Additionally, the results show that lean practices substantially impact environmental performance, particularly in reducing water consumption, energy consumption cost, and solid waste.

Table 3: The results of Friedman test

| Section | Chi-Square | df | Asymp.Sig. |

| S1 | 2.330 | 4 | 0.703 |

| S2 | 8.348 | 3 | 0.023 |

| S3 | 23.952 | 2 | <0.01 |

| S4 | 10.010 | 1 | <0.01 |

| S5 | 15.662 | 2 | <0.01 |

| S6 | 7.164 | 4 | 0.086 |

| S7 | 5.128 | 2 | 0.37 |

| S8 | 2.402 | 2 | 0.311 |

| S9 | 22.611 | 2 | <0.01 |

| S10 | 6.211 | 3 | 0.063 |

Table 4: The performance of lean practices

| Section | Code | Mean |

| Operational performance | Reduction of the production cycle time | 3.82 |

| Reduction in delivery time | 3.82 | |

| Increasing productivity | 3.96 | |

| Reduction of customer complaints | 3.79 | |

| Production cost reduction | 4 | |

| Product Quality Improvement | 4 | |

| Scrap Rate Reduction | 3.89 | |

| Environmental performance | Reduction of hazardous/toxic material consumption | 3.5 |

| Minimization of atmospheric emissions (CO2 and other gases) | 3.36 | |

| Minimization of water consumption | 3.82 | |

| Solid waste reduction | 3.68 | |

| Reduction of environmental accidents | 3.61 | |

| Reducing CO2 emissions from transportation | 3.36 | |

| Lowering the cost of energy consumption | 3.79 | |

| Food Waste Reduction | 3.5 |

6. Discussion

The significance of this study’s findings lies in their evaluation and discussion specifically within the context of Moroccan agri-food companies. The results indicate that the majority of these companies have already adopted some form of lean practices. The most commonly implemented practices in this sector include those related to suppliers, customers, employees, and preventive maintenance. This aligns with the findings of [12], who studied the utilization of lean practices in European food SMEs, except that they observed a lower implementation of employee-related practices. However, this study also found a difference compared to [48], in Moroccan companies, the flow-related practices are more widely adopted, whereas European SMEs implement these practices less frequently. On the other hand, both this study and the results of [48] show that the pull practices have low implementation.

It appears that some lean practices associated with Pull are challenging to implement in food companies. The results suggest that this is largely due to the limited use of Kanban. The reason for this weakness could be attributed to the difficulty in predicting demand within the agri-food sector. The limited utilization of Kanban emerged as a prominent factor contributing to this difficulty, which can be linked to the inherent unpredictability of demand in the agri-food sector [56]. For instance, weather conditions greatly influence the demand for certain products, with a sunny afternoon witnessing a significant surge compared to a rainy afternoon [48].

Furthermore, the results indicate a low adoption of techniques aimed at reducing setup time. This finding can be explained by the intricate nature of production processes, involving diverse materials and compositions. It appears paradoxical that despite the inherent characteristics of the food sector, such as perishability and short production cycles [48], some lean practices face challenges in implementation within this industry.

This study demonstrates the substantial impact of lean practices on both environmental and operational performance, with notable effects such as reduced production costs, enhanced product quality, decreased water consumption, and lower energy consumption costs. One hypothesis could focus on the potential impact of lean practices on cost reduction and efficiency in Moroccan agri-food companies. It could be posited that by implementing lean principles such as waste reduction, just-in-time production, and continuous improvement, these companies can achieve significant cost savings and enhance overall operational performance. Other hypothesis could be proposed that by adopting lean methodologies, agri-food companies can enhance product quality, safety, and compliance with regulatory standards.

A key challenge lies in reconciling lean practices with the specific requirements of the agri-food sector, which deals with perishable goods, complex supply chains, and stringent food safety regulations. The active involvement of governmental agencies and industry associations in promoting lean practices can provide the necessary resources, knowledge-sharing platforms, and incentives to facilitate its adoption. However, certain barriers may impede the effective implementation of lean practices in Moroccan agri-food companies. These can include resistance to change, insufficient awareness or comprehension of lean principles, and inadequate investment in technology and infrastructure.

7. Conclusion

This study offers an overview of the growth of the agri-food industry, with a concentrate on identifying the most commonly implemented lean practices in Moroccan companies and how they can improve operational and environmental performance in the sector. However, it should be noted that the extent of this study is restricted to the lean practices of agri-food companies. Despite this limitation, the results provide valuable insights for company managers by giving them an understanding of the level of lean practice adoption in the Moroccan agribusiness sector and their effects on operational and environmental performance. This paper offers valuable practical implications for managers by presenting an overview of the present status of implementing lean manufacturing in food processing SMEs. While one limitation of this study is its focus on a limited sample of food companies in Morocco, it nonetheless serves as a foundation for future empirical research in this domain. Given the significance of the food sector in the forthcoming years, further exploration and investigation in this area are essential to enhance our understanding and application of lean practices in the industry. Future research could expand the study to cover agribusinesses in other developing countries, in order to generalize the findings. The results of this study have the potential to inform the creation of a tool to assess lean practices in the Moroccan agri-food companies.

Conflict of Interest

The authors declare no conflict of interest.

Acknowledgment

The authors would like to thank the anonymous reviewers and editor for their helpful suggestions that greatly improved the original manuscript.

- F.J. Krafick, “Triumph of the Lean Production System,” Sloan Management Review, 30(1), 41–52, 1988.

- J.P. Womack, D.T. Jones, D. Roos, “The machine that changed the world,” Business Horizons, 35(3), 81–82, 1992, doi:10.1016/0007-6813(92)90074-J.

- R. Shah, P.T. Ward, “Lean manufacturing: context, practice bundles, and performance,” Journal of Operations Management, 21(2), 129–149, 2003.

- F. Bouhannana, “Integrating Lean , Green and Agile in Supply Chain Management : A Systematic Literature Review Laboratory of Systems Engineering and Decision Making,” 12–14, 2019.

- R. Mann, D. Kehoe, “An Evaluation of the Effects of Quality Improvement Activities on Business Performance,” International Journal of Quality & Reliability Management, 11(4), 29–44, 1994, doi:10.1108/02656719410057935.

- J. Bhamu and K. Singh Sangwan, “Lean manufacturing: literature review and research issues,” Int. J. Oper. Prod. Manag., 34(7), 876–940, 2014, doi:10.3390/f9040186.

- F. Bouhannana and A. El Korchi, “A systematic literature review to measure lean, green and agile in manufacturing organisations,” Int. J. Oper. Res., 1(1), 1, 2022, doi: 10.1504/IJOR.2022.10050966.

- V. Yadav, R. Jain, M.L. Mittal, A. Panwar, A. Lyons, “The impact of lean practices on the operational performance of SMEs in India,” Industrial Management and Data Systems, 119(2), 317–330, 2019, doi:10.1108/IMDS-02-2018-0088.

- R. Borges Lopes, F. Freitas, I. Sousa, “Application of lean manufacturing tools in the food and beverage industries,” Journal of Technology Management & Innovation, 10(3), 120–130, 2015.

- Boston Consulting Group, “Lean food-and-beverage manufacturing: Lower costs, better products, improved sustainability,” 2015, doi:10.1109/ISBIM.2008.40.

- P. Centobelli, R. Cerchione, and R. Singh, “The impact of leanness and innovativeness on environmental and financial performance: Insights from Indian SMEs,” Int. J. Prod. Econ., 212, 111–124, 2019, doi:10.1016/j.jclepro.2013.10.015.

- M. Dora, M. Kumar, D. Van Goubergen, A. Molnar, X. Gellynck, “Food quality management system: Reviewing assessment strategies and a feasibility study for European food small and medium-sized enterprises,” Food Control, 31(2), 607–616, 2013.

- E. Psomas, J. Antony, N. Bouranta, “Assessing lean adoption in food SMEs: evidence from Greece,” International Journal of Quality & Reliability Management, 35(1), 64–81, 2018.

- A. Marques-Mendes, M.J. Santos, “Strategic CSR: an integrative model for analysis,” Social Responsibility Journal, 12(2), 363–381, 2016.

- T. Bonavia, J.A. Marin, “An empirical study of lean production in the ceramic tile industry in Spain,” International Journal of Operations & Production Management, 26(5), 505–531, 2006.

- T. Brush, A. Karnani, “Impact of plant size and focus on productivity: An empirical study,” Management Science, 42(7), 1065–1081, 1996.

- R. Shah, P.T. Ward, “Defining and developing measures of lean production,” Journal of Operations Management, 25(4), 785–805, 2007.

- A. Farissi, M. El Oumami, Z. Beidouri, “Assessing Lean Adoption in Food Companies : The Case of Morocco,” 12(May 2020), 5–14, 2021, doi:10.14716/ijtech.v12i1.3837.

- T. Bortolotti, S. Boscari, P. Danese, “Successful lean implementation: Organizational culture and soft lean practices,” International Journal of Production Economics, 160, 182–201, 2015.

- F. Bouhannana and A. Elkorchi, “Trade-offs among lean, green and agile concepts in supply chain management: Literature review,” in 2020 IEEE 13th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), IEEE, 2020, 1–5, doi: 10.1109/LOGISTIQUA49782.2020.9353930

- M. Ghosh, “Lean manufacturing performance in Indian manufacturing plants,” Journal of Manufacturing Technology Management, 24(1), 113–122, 2013.

- S. Bhasin, “Prominent obstacles to lean,” International Journal of Productivity and Performance Management, 61(4), 403–425, 2012.

- A. Muñoz-villamizar, J. Santos, P. Grau, E. Viles, J. Santos, D. Sebastian, P. Grau, “Trends and gaps for integrating lean and green management in the agri-food sector,” 2019, doi:10.1108/BFJ-06-2018-0359.

- P. Carlborg, D. Kindström, C. Kowalkowski, “A lean approach for service productivity improvements: synergy or oxymoron?,” Managing Service Quality: An International Journal, 23(4), 291–304, 2013.

- G. Onofrei, J. Prester, B. Fynes, P. Humphreys, F. Wiengarten, “The relationship between investments in lean practices and operational performance: Exploring the moderating effects of operational intellectual capital,” International Journal of Operations & Production Management, 39(3), 406–428, 2019.

- R.R. Fullerton, W.F. Wempe, “Lean manufacturing, non‐financial performance measures, and financial performance,” International Journal of Operations & Production Management, 2009.

- K.O. Cua, K.E. McKone-Sweet, R.G. Schroeder, “Improving performance through an integrated manufacturing program,” Quality Management Journal, 13(3), 45–60, 2006.

- S. Taj, L. Berro, “Application of constrained management and lean manufacturing in developing best practices for productivity improvement in an auto‐assembly plant,” International Journal of Productivity and Performance Management, 55(3/4), 332–345, 2006.

- C. Droge, J. Jayaram, S.K. Vickery, “The effects of internal versus external integration practices on time-based performance and overall firm performance,” Journal of Operations Management, 22(6), 557–573, 2004.

- B.B. Flynn, E.J. Flynn, “An exploratory study of the nature of cumulative capabilities,” Journal of Operations Management, 22(5), 439–457, 2004.

- P. Nieminen, J. Takala, “Achieving better on-time-delivery performance with the help of internal dependencies in the production,” International Journal of Management and Enterprise Development, 3(1–2), 181–190, 2006.

- J.A. Garza-Reyes, V. Kumar, S. Chaikittisilp, K.H. Tan, “The effect of lean methods and tools on the environmental performance of manufacturing organisations,” International Journal of Production Economics, 200, 170–180, 2018.

- K. Zokaei and D. Simons, “Performance improvements through implementation of lean practices: a study of the UK red meat industry,” Int. Food Agribus. Manag. Rev., 9(1030-2016–82410), 30–53, 2006, doi:10.1136/bmj.322.7278.98.

- M. Asmae, E.-N. Abdelali, and H. Brahim, “Critical success factors of Lean implementation in Moroccan agro food supply chain,” in 2022 14th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), May 2022, 1–6. doi: 10.1109/LOGISTIQUA55056.2022.9938121.

- H. ROCHDI and M. EL ATASSI, “Impact de l’intégration relationnelle inter-organisationnelle sur la performance logistique des chaines logistique d’exportation: Cas des CLE des primeurs de la région Sous-Massa,” Rev. Int. Cherch., 2(2), 2021, doi:10.1007/s00170-012-3988-4.

- N. Bateman, “Sustainability: the elusive element of process improvement,” Int. J. Oper. Prod. Manag., 2005, doi:10.1016/j.ijpe.2018.09.031.

- M. Dora, M. Kumar, X. Gellynck, “Determinants and barriers to lean implementation in food-processing SMEs–a multiple case analysis,” Production Planning & Control, 27(1), 1–23, 2016.

- P. F. Larasati and N. B. Mulyono, “Exploring The Current State Of Lean Practices In The Agri-Food Supply Chain: A Systematic Literature Review,” Int. J. Appl. Bus. Res., 168–186, Jul. 2022, doi: 10.35313/ijabr.v4i2.269.

- D. Powell, S. Lundeby, L. Chabada, and H. Dreyer, “Lean Six Sigma and environmental sustainability: the case of a Norwegian dairy producer,” Int. J. Lean Six Sigma, 8(1), 53–64, 2017.

- B. Heymans, “Lean manufacturing and the food industry,” J. Technol. Manag. Innov., 10(3), 120–30, 2015, doi:10.1007/978-3-642-40081-0.

- V. Sanchez Rodrigues, M. Kumar, “Synergies and misalignments in lean and green practices: a logistics industry perspective,” Production Planning & Control, 30(5–6), 369–384, 2019.

- B. Heymans, “Lean manufacturing and the food industry,” J. Technol. Manag. Innov., 10(3), 120–30, 2015, doi:10.1007/s40092-019-0313-y.

- H. De Steur, J. Wesana, M. K. Dora, D. Pearce, and X. Gellynck, “Applying Value Stream Mapping to reduce food losses and wastes in supply chains: A systematic review,” Waste Manag., 58, 359–368, 2016, doi:10.1016/j.jclepro.2017.09.171.

- D. Pearce, M. Dora, J. Wesana, and X. Gellynck, “Toward sustainable primary production through the application of lean management in South African fruit horticulture,” J. Clean. Prod., 313, 127815, 2021.

- M. Melin and H. Barth, “Value stream mapping for sustainable change at a Swedish dairy farm,” Int. J. Environ. Waste Manag., 25(1), 130–140, 2020, doi:10.1016/j.jclepro.2018.01.121.

- N. E. Caicedo Solano, G. A. García Llinás, and J. R. Montoya-Torres, “Towards the integration of lean principles and optimization for agricultural production systems: a conceptual review proposition,” J. Sci. Food Agric., 100(2), 453–464, 2020, doi:10.1108/JHOM-09-2016-0165.

- N. V. K. Jasti, A. Sharma, and R. Kodali, “Lean to green supply chain management: a case study,” J. Environ. Res. Dev., 6(3) 890–899, 2012, doi:10.1016/j.ijpe.2021.108060.

- M. Dora, D. van Goubergen, M. Kumar, A. Molnar, X. Gellynck, “Application of lean practices in small and medium-sized food enterprises,” British Food Journal, 116(1), 125–141, 2014, doi:10.1108/BFJ-05-2012-0107.

- U. Lehtinen and M. Torkko, “The lean concept in the food industry: A case study of contract a manufacturer,” J. Food Distrib. Res., 36(856-2016–56436), 57–67, 2005, doi:10.1016/j.procir.2016.05.067.

- N. Upadhye, S. G. Deshmukh, and S. Garg, “Lean manufacturing in biscuit manufacturing plant: a case,” Int. J. Adv. Oper. Manag., 2(1–2), 108–139, 2010.

- W.S. Al-Ghwayeen, A.B. Abdallah, “Green supply chain management and export performance: The mediating role of environmental performance,” Journal of Manufacturing Technology Management, 29(7), 1233–1252, 2018, doi:10.1108/JMTM-03-2018-0079.

- A. Al-Sheyadi, L. Muyldermans, K. Kauppi, “The complementarity of green supply chain management practices and the impact on environmental performance,” Journal of Environmental Management, 242, 186–198, 2019.

- M. Dieste, R. Panizzolo, “The effect of lean practices on environmental performance: An empirical study,” Lean Engineering for Global Development, 225–258, 2019.

- M. Feng, W. Yu, X. Wang, C.Y. Wong, M. Xu, Z. Xiao, “Green supply chain management and financial performance: The mediating roles of operational and environmental performance,” Business Strategy and the Environment, (April 2017), 1–14, 2018, doi:10.1002/bse.2033.

- S. Laari, J. Töyli, L. Ojala, “The effect of a competitive strategy and green supply chain management on the financial and environmental performance of logistics service providers,” Business Strategy and the Environment, 27(7), 872–883, 2018, doi:10.1002/bse.2038.

- M. Trujillo-gallego, W. Sarache, M.A. Sellitto, “Environmental performance in manufacturing companies : a benchmarking study performance,” 2020, doi:10.1108/BIJ-05-2020-0225.

- A. Belhadi, F.E. Touriki, S. El, “Development of a Lean Assessment Tool for Small and Medium Sized-Enterprises,” 361–369, doi:10.1007/978-3-319-58409-6.

- R. Shah and P. T. Ward, “Defining and developing measures of lean production,” J. Oper. Manag., 25(4), 785–805, Jun. 2007, doi: 10.1016/j.jom.2007.01.019.

- B. Abdelilah, A. El Korchi, M. Amine Balambo, “Agility as a combination of lean and supply chain integration: how to achieve a better performance,” International Journal of Logistics Research and Applications, 1–29, 2021.