A Novel Approach for Estimating the Service Lifetime of Transformers within Distributed Solar Photovoltaic (DSPV) Systems

Volume 6, Issue 3, Page No 126–130, 2021

Adv. Sci. Technol. Eng. Syst. J. 6(3), 126–130 (2021);

DOI: 10.25046/aj060314

DOI: 10.25046/aj060314

Keywords: Renewable energy, Transformer, Degree of polymerization, Furan, Service lifetime

The rapid transformation of the energy sector in South Africa towards renewable energy (RE) production calls for the management of assets to keep pace with the ongoing developments in a reliable manner. Aging assets, increasing energy needs and reliable supply of energy without load shedding are some of the challenges utilities are facing in South Africa. In resolving these challenge, imaginative solutions are required to maintain the installed assets and determining the viability of refurbishment, replacement or upgrading. In the current work, an extension of the author’s previous work, a novel approach for estimating the service lifetime of transformers within Distributed Solar Photovoltaic (DSPV) Systems in South Africa is introduced. This experiential form has been derived by extensive experimental trials. The proposed approach is initially employed to evaluate the Degree of polymerization (DP) of cellulose insulation based on measured furan (2FAL) contents of 9 case scenarios. The calculated DP is then used to evaluate the service lifetime of these units. In efforts to authenticate the proposed approach, a comparative study is conducted against 5 other models. Finally, the proposed approach is compared with the results of the measured DP. It is observed that the proposed approach produce accurate estimates with an approximation not exceeding 1% and 2.2% from the measured DP and service lifetime respectively.

1. Introduction

Oil-immersed Distributed Solar Photovoltaic (DSPV) system transformers are commonly designed for a service lifetime of about 30 years [1], [2]. During service, the cellulose insulation degrades under the interactive effects emanating from electrical, thermal and chemical components. The mechanism of degradation of cellulose insulation (DCI) is reliant on the conditions such as harmonics, distorted load cycle and excessive heating that the transformer may be subjected to during their designed service lifetime. There are four underlying factors that elevate the DCI viz. moisture, oxygen, acid and excessive temperature. The oil-cellulose insulation system in DSPV transformers is prevalent on account of its cost-effectiveness and capacity to withstand severe electrical and thermal stresses [3], [4]. Due to the costly exercise of replacing field transformers, the utility owners will keep the units in service while performing periodical online monitoring and routine testing of the insulation system. Therefore, diagnostic techniques suchlike Dissolved Gas Analysis (DGA) and Furan Analysis (FA) are increasingly being recognized as efficacious and irrefutable procedures to evaluate the reliability of oil-cellulose insulation system.

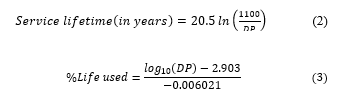

The chemical structure of cellulose insulation is composed of strings of anhydroglucoses linked via glycosidic bonds [5] – [7]. These bonds have relatively low temperature resistance in relation to hydrocarbon bonds prevailing in DSPV transformer oil [8]. This degradation phenomenon triggers depolymerisation which leads to degraded forms of glucose as shown in Figure 1 [9]. The formation of glucose will further degrade to forge furans, water and combustible gases [9 – 11].

Figure 1: Thermal degradation of cellulose insulation

Figure 1: Thermal degradation of cellulose insulation

The generation of Furan compounds (FCs) is distinctly on the cellulose insulation and seemed to be kind of stable at elevated temperatures reaching 140℃ within the transformer oil [12]. The existence of FCs remains in oil-immersed transformers even at elevated temperatures geared towards providing a divulgence to the condition of the cellulose insulation.

The FCs 2-FAL, 5-hydroxymethyl-2-furaldehyde, 2-acetylfuran, 5-methyl-2-furaldehyde, and 2-furfurolare are the most widely known in the transformer manufacturing industry. The FC 2-FAL is most widely-used in the industry relating its content to the cellulose degree of polymerization (DP) which is the number of monomeric units in the cellulose polymer [13] – [14]. Furans are a constituent of the products of degradation of the transformer cellulose insulation. During service, they are moderately dissolvable in the transformer oil. The relationship between the transformer state and the concentration of the furan content in the oil is as shown in Table below.

Table 1: 2FAL concentration criterion

| Status | Concentration [in ppm] |

| Healthy | 2FAL < 0.5 |

| Satisfactory | 0.5 ≤ 2FAL ≤ 1 |

| Warning | 1.1 ≤ 2FAL ≤ 1.5 |

| Poor | 1.6 ≤ 2FAL ≤ 2 |

| Extremely poor | 2FAL ≥ 2.1 |

In the current work, an extension of the author’s previous work [14], a novel approach for estimating the service lifetime of transformers within DSPV Systems in South Africa is introduced. This experiential form has been derived by extensive experimental trials. The proposed approach is initially employed to evaluate the DP of cellulose insulation based on measured 2FAL contents on a fleet of selected case scenarios. The calculated DP is then used to evaluate the service lifetime of these units. In efforts to authenticate the proposed approach, a comparative study is conducted against 5 other models. Finally, the proposed approach is compared with the results of the measured DP. It is observed that the proposed approach produce accurate estimates with an approximation not exceeding 1% and 2.2% from the measured DP and service lifetime respectively.

2. DP Models

In this day and age, the aging condition of transformers can be established by mathematical modelling which launch the relationship between furan concentrations, DP, and transformer service lifetime.

2.1. Existing DP models

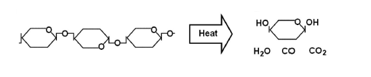

Several authors in [15] – [19] have established mathematical formulae which relate the furan concentrations and the measure of the DP of the insulation material. An illustration of this relationship based upon this methods is presented in Figure 2. A Further in [20], mathematical formulae has been developed to describe the relationship between DP and the service lifetime. In order to attain a thread that binds the furan concentrations and the DP of the cellulose insulation (CI), the DP methods are compared at different furan contents. The comparison indicate that the methods can evaluate the DP ranging from 1 to 14.

Figure 2: Correlation between the DP and Furans (2FAL)

Figure 2: Correlation between the DP and Furans (2FAL)

The development, identification and behaviour of furan compounds has been described by [21], [22] and [23]. In the next sub-section a comprehensive description of the model proposed in this work is presented.

2.2. Proposed model

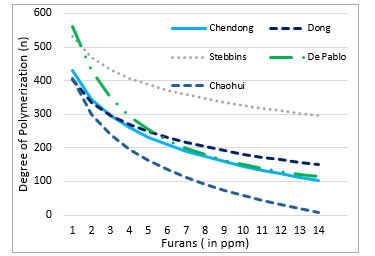

Based upon observational data, a fleet of mineral oil samples were analysed to develop a novel DP model for transformers serving exclusively in distributed solar photovoltaic systems. The proposed model can be applied to ascertain the DP of cellulose insulation with accuracy following 2-FAL measurement in the oil. The proposed model is as shown in Eq. (1) below.

The concentration (in ppm) of the furan content 2-FAL can be easily substituted in the formulae to obtain the DP of a transformer.

The concentration (in ppm) of the furan content 2-FAL can be easily substituted in the formulae to obtain the DP of a transformer.

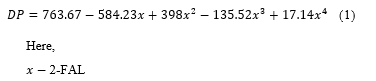

2.3. Transformer Service Lifetime

The transformer age can be obtained by applying Eq. (2) and Eq. (3) below [20]. With the knowledge of the DP of the transformer, the service lifetime can be ascertained.

3. Case Scenario

In this section, the 2FAL results of 9 mineral-oil immersed DSPV transformers are considered. The gas concentrations are obtained from oil samples collected from various DSPV facilities. The studied transformers range from 100kVA to 20 000 kVA as shown in Table 2.

Table 2: Case Studies

| Case | Rating (kVA) | Voltage (kV) | 2FAL |

| A | 1500 | 6.6/0.5 | 1.778 |

| B | 1500 | 6.6/0.5 | 2.377 |

| C | 100 | 0.525/0.4 | 3.00 |

| D | 150 | 0.525/0.4 | 1.601 |

| E | 20 000 | 6.6/0.5 | 0.676 |

| F | 20 000 | 6.6/0.5 | 0.231 |

| G | 20 000 | 88/6.6 | 0.143 |

| H | 4000 | 6.6/0.5 | 1.513 |

| I | 2000 | 6.6/0.5 | 1.563 |

The 2-FAL contents were measured during the routine maintenance of the transformers.

3.1. Degree of Polymerization

In order to determine the accuracy of the formulae presented by the authors in [15] – [19] and the proposed formula in the current work, the DP for the studied cases are evaluated and tabulated as a shown in Table 3 below. Stebbins [18] results are observed to yield a significantly protruding DP values compared to all the other methods.

Table 3: DP of studied transformers using furan compounds (2FAL)

| Case | 2FAL | Chendong

[15] |

De Pablo

[16] |

Dong

[17] |

Stebbins

[18] |

Chaohui

[19] |

Proposed |

| A | 1,778 | 360 | 454 | 347 | 480 | 318 | 393 |

| B | 2,377 | 324 | 396 | 319 | 454 | 275 | 351 |

| C | 3 | 295 | 349 | 297 | 433 | 240 | 322 |

| D | 1,601 | 373 | 474 | 357 | 489 | 334 | 405 |

| E | 0,676 | 480 | 622 | 440 | 565 | 464 | 512 |

| F | 0,231 | 613 | 731 | 543 | 660 | 626 | 648 |

| G | 0,143 | 673 | 757 | 589 | 703 | 699 | 688 |

| H | 1,513 | 380 | 485 | 363 | 494 | 343 | 411 |

| I | 1,563 | 376 | 479 | 360 | 491 | 338 | 408 |

These DP values are a measure of the realistic aging of the cellulose insulation, which governs the transformer’s service lifetime. And so, it is possible to evaluate the service lifetime of a transformer and make comparison with real life by means of furan concentration within the oil. The latter improves the assessment of the reliability of service transformers.

3.2. Transformer Service Lifetime

Further to previous sub-section, the remaining service lifetime of the studied cases is determined using the DP results as presented in Table 4 for all models.

Table 4: Remaining service lifetime estimation

| Case | 2FAL | Chendong

[15] |

De Pablo

[16] |

Dong

[17] |

Stebbins

[18] |

Chaohui

[19] |

Proposed |

| A | 1,778 | 22,90 | 18,16 | 23,64 | 17,02 | 25,41 | 21,12 |

| B | 2,377 | 25,06 | 20,97 | 25,35 | 18,15 | 28,44 | 23,43 |

| C | 3 | 26,97 | 23,53 | 26,84 | 19,10 | 31,25 | 25,18 |

| D | 1,601 | 22,17 | 17,25 | 23,05 | 16,62 | 24,42 | 20,49 |

| E | 0,676 | 17,00 | 11,70 | 18,78 | 13,65 | 17,68 | 15,66 |

| F | 0,231 | 11,98 | 8,38 | 14,47 | 10,46 | 11,55 | 10,84 |

| G | 0,143 | 10,08 | 7,65 | 12,80 | 9,18 | 9,31 | 9,62 |

| H | 1,513 | 21,79 | 16,78 | 22,74 | 16,41 | 23,90 | 20,17 |

| I | 1,563 | 22,01 | 17,05 | 22,92 | 16,53 | 24,20 | 20,35 |

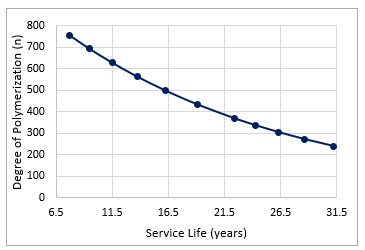

The relationship between the DP and the service lifetime is illustrated by Figure 3 below.

Figure 3: Correlation between the DCI and Furans (2FAL)

Figure 3: Correlation between the DCI and Furans (2FAL)

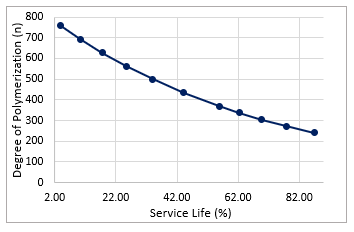

Figure 4: Correlation between the DP and %Service lifetime

Figure 4: Correlation between the DP and %Service lifetime

It can be observed that as the transformer life is service is longer, the DP decreases. In Table 5, the percentage of the service lifetime for all cases is presented.

Table 5: Percentage of transformer service lifetime

| Case | 2FAL | Chendong [15] | De Pablo

[16] |

Dong

[17] |

Stebbins

[18] |

Chaohui

[19] |

Proposed |

| A | 1,778 | 57,58 | 40,90 | 60,18 | 36,89 | 66,42 | 51,32 |

| B | 2,377 | 65,18 | 50,79 | 66,21 | 40,87 | 77,09 | 59,46 |

| C | 3 | 71,92 | 59,81 | 71,44 | 44,22 | 86,95 | 65,61 |

| D | 1,601 | 55,02 | 37,70 | 58,12 | 35,51 | 62,93 | 49,10 |

| E | 0,676 | 36,83 | 18,18 | 43,10 | 25,03 | 39,23 | 32,13 |

| F | 0,231 | 19,16 | 6,50 | 27,93 | 13,81 | 17,65 | 15,15 |

| G | 0,143 | 12,48 | 3,94 | 22,07 | 9,31 | 9,77 | 10,88 |

| H | 1,513 | 53,67 | 36,06 | 57,03 | 34,77 | 61,11 | 47,98 |

| I | 1,563 | 54,44 | 37,00 | 57,66 | 35,19 | 62,15 | 48,62 |

The percentage of service lifetime is observed to correlate with the data presented in Table 4. The correlation between the DP and the percentage service lifetime is illustrated by Figure 4.

It is observed that the DP decreases with respect to the aging of the transformer.

3.3. Practical Results

In this subsection, the values of the measured DP and 2FAL of the nine studied transformers that operate in various DSPV systems are presented in Table 6.

Table 6: Percentage of service lifetime

| Case | 2FAL | Measured DP | Service Life | % Service Lifetime |

| A | 1,778 | 389 | 21,30 | 51,96 |

| B | 2,377 | 352 | 23,35 | 59,16 |

| C | 3 | 322 | 25,20 | 65,67 |

| D | 1,601 | 404 | 20,56 | 49,35 |

| E | 0,676 | 515 | 15,57 | 31,78 |

| F | 0,231 | 641 | 11,08 | 15,99 |

| G | 0,143 | 694 | 9,46 | 10,29 |

| H | 1,513 | 412 | 20,15 | 47,92 |

| I | 1,563 | 411 | 20,20 | 48,10 |

3.4. Results comparison

The error of estimation for DP, service lifetime and percentage service lifetime against the measured results are presented in this subsection for the studied DSPV transformers. In Table 7, it can be observed that the proposed formula gives an accurate estimation of the DP in comparison to the other models across all nine cases.

Table 7: Error of estimation: DP

| Case | Chendong

[15] |

De Pablo

[16] |

Dong

[17] |

Stebbins

[18] |

Chaohui

[19] |

Proposed |

| A | 7,5% | 16,6% | 10,8% | 23,2% | 18,2% | 0,88% |

| B | 8,0% | 12,3% | 9,3% | 28,9% | 22,0% | 0,42% |

| C | 8,3% | 8,5% | 7,7% | 34,6% | 25,5% | 0,09% |

| D | 7,6% | 17,5% | 11,4% | 21,2% | 17,2% | 0,36% |

| E | 6,8% | 20,8% | 14,5% | 9,8% | 9,8% | 0,48% |

| F | 4,3% | 14,1% | 15,3% | 3,1% | 2,3% | 1,17% |

| G | 3,0% | 9,2% | 15,1% | 1,4% | 0,7% | 0,81% |

| H | 7,7% | 17,9% | 11,9% | 20,0% | 16,7% | 0,09% |

| I | 8,4% | 16,6% | 12,4% | 19,6% | 17,7% | 0,72% |

It is observed that the proposed formula produces accurate estimates with an approximation not exceeding 1% from the measured DP. As a result, it is evident that the proposed formula achieves a higher accuracy. In Table 8, the error of estimation of the calculated and measured results of the service lifetime is presented.

Table 8: Error of estimation: Service Life

| Case | Chendong

[15] |

De Pablo

[16] |

Dong

[17] |

Stebbins

[18] |

Chaohui

[19] |

Proposed |

| A | 7,5% | 14,7% | 11,0% | 20,1% | 19,3% | 0,85% |

| B | 7,3% | 10,2% | 8,6% | 22,3% | 21,8% | 0,37% |

| C | 7,0% | 6,6% | 6,5% | 24,2% | 24,0% | 0,07% |

| D | 7,8% | 16,1% | 12,1% | 19,1% | 18,8% | 0,35% |

| E | 9,2% | 24,8% | 20,7% | 12,3% | 13,6% | 0,64% |

| F | 8,1% | 24,4% | 30,6% | 5,6% | 4,3% | 2,16% |

| G | 6,6% | 19,1% | 35,4% | 2,9% | 1,6% | 1,77% |

| H | 8,1% | 16,7% | 12,9% | 18,5% | 18,6% | 0,09% |

| I | 8,9% | 15,6% | 13,5% | 18,2% | 19,8% | 0,74% |

It is observed that the proposed formula produce accurate estimates with an approximation not exceeding 2.2% from the measured service lifetime.

Table 9: Error of estimation: % of transformer service life

| Case | Chendong [15] | De Pablo [16] | Dong

[17] |

Stebbins

[18] |

Chaohui

[19] |

Proposed |

| A | 10,8% | 21,3% | 15,8% | 29,0% | 27,8% | 1,22% |

| B | 10,2% | 14,2% | 11,9% | 30,9% | 30,3% | 0,51% |

| C | 9,5% | 8,9% | 8,8% | 32,7% | 32,4% | 0,10% |

| D | 11,5% | 23,6% | 17,8% | 28,1% | 27,5% | 0,52% |

| E | 15,9% | 42,8% | 35,6% | 21,2% | 23,4% | 1,10% |

| F | 19,8% | 59,4% | 74,7% | 13,7% | 10,4% | 5,27% |

| G | 21,3% | 61,7% | 114,5% | 9,5% | 5,1% | 5,71% |

| H | 12,0% | 24,8% | 19,0% | 27,4% | 27,5% | 0,13% |

| I | 13,2% | 23,1% | 19,9% | 26,8% | 29,2% | 1,09% |

It is observed that the proposed formula produce accurate estimates with an approximation not exceeding 5.8% from the measured percentage service lifetime.

At large, the overall assessment of the proposed formula presented in this work presented the highest precision in the estimation of the DP of the cellulose insulation in comparison to the other 5 models.

4. Conclusion

The knowledge of the transformer service lifetime and the specific point in time that is suitable to replace transformers is critical for utility owners. These determinations are dependent upon the condition of the cellulose and liquid insulation. In practical terms, knowledge on the condition of insulation is crucial to undertake adequate life cycle and reliability management of transformers in the facility. In the transformer industry, the physical chemistry of oil is prevalent in the evaluation of the transformer life cycle considering that oil samples can easily be extracted at site to the laboratory for analysis.

In the current work, an extension of the author’s previous work [14], a novel approach for estimating the service lifetime of transformers within DSPV Systems in South Africa was introduced. This experiential form has been derived by extensive experimental trials. The proposed approach was initially employed to evaluate the DP of cellulose insulation based on measured 2-FAL contents (in ppm) of 9 case scenarios. The calculated DP was then used to evaluate the service lifetime of these units. In efforts to authenticate the proposed approach, a comparative study was conducted against 5 other models. Finally, the proposed approach was compared with the results of the measured DP. It was observed that the proposed approach produce accurate estimates with an approximation not exceeding 1% and 2.2% from the measured DP and service lifetime respectively.

In future work, the authors will test the proposed formula with other different transformers. Further, the authors will carry out work related to the reliability analysis of DPSV transformers based upon their operating hours in service by apply the Weibull distribution technique and support vector machine to classify their reliability.

Conflict of Interest

The authors declare no conflict of interest.

- P. Mann, “Determination of transformer life expectancy,” in Electrical Engineering, 82 (8), 512-514, 1963, doi: 10.1109/EE.1963.6540988.

- D. Martin, Y. Cui, T. Saha, N. Lelekakis and J. Wijaya, “Life estimation techniques for transformer insulation,” 2013 Australasian Universities Power Engineering Conference (AUPEC), Hobart, TAS, 1-6, 2013, doi: 10.1109/AUPEC.2013.6725457.

- T. A. Prevost and T. V. Oommen, “Cellulose insulation in oil-filled power transformers: Part I – history and development,” in IEEE Electrical Insulation Magazine, 22 (1), 28-35, 2006, doi: 10.1109/MEI.2006.1618969.

- B. A. Thango, J. A. Jordaan and A. F. nnachi, “Stray Gassing of Transformer Oil in Distributed Solar Photovoltaic (DSPV) Systems,” 2020 6th IEEE International Energy Conference (ENERGYCon), Gammarth, Tunis, Tunisia, 484-488, 2020, doi: 10.1109/ENERGYCon48941.2020.9236522.

- L. Cheim, D. Platts, T. Prevost and S. Xu, “Furan analysis for liquid power transformers,” in IEEE Electrical Insulation Magazine, 28 (2), no. 2, 8-21, 2012, doi: 10.1109/MEI.2012.6159177.

- J. R. Sans, K. M. Bilgin and J. J. Kelly, “Large-scale survey of furanic compounds in operating transformers and implications for estimating service life,” Conference Record of the 1998 IEEE International Symposium on Electrical Insulation (Cat. No.98CH36239), Arlington, VA, USA, 2, 543-553, 1998 doi: 10.1109/ELINSL.1998.694852.

- M. T. Imani, K. Homeier, P. Werle and G. Dräger, “How Far are Furan Compounds Reliable Indicators for Thermal Aging of Oil Impregnated Cellulose Insulation?,” 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, 438-441, 2018 doi: 10.1109/CEIDP.2018.8544859.

- C. Zhang and J. M. K. Macalpine, “Furfural Concentration in Transformer Oil as an Indicator of Paper Ageing, Part 1: A Review,” 2006 IEEE PES Power Systems Conference and Exposition, Atlanta, GA, 1088-1091, 2006, doi: 10.1109/PSCE.2006.296461.

- G. Xia and G. Wu, “Study on the impact of initial moisture contents on ageing characteristics of transformer oil-paper insulation,” 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, 1-4, 2016, doi: 10.1109/ICHVE.2016.7800632.

- D. Suksawat, K. Atthaphotpong, K. Takboontam, K. Satirapattanakiat, C. Raphephat and N. Pattanadech, “Furan Analysis of Oil Impregnated Paper Aged by Chemical Stress,” 2020 8th International Conference on Condition Monitoring and Diagnosis (CMD), Phuket, 422-425, 2020, doi: 10.1109/CMD48350.2020.9287264.

- A. Akshatha, R. Kumar A, S. Rajan J and H. Ramachandra, “Studies on chemical and dielectric phenomena in paper – oil insulation due to sulphur compounds in mineral oil,” 2014 IEEE Electrical Insulation Conference (EIC), Philadelphia, PA, 281-285, 2014, doi: 10.1109/EIC.2014.6869392.

- “IEEE Guide for Evaluation and Reconditioning of Liquid Immersed Power Transformers,” in IEEE Std C57.140-2017 (Revision of IEEE Std. C57.140-2006), 1-88, 2017, doi: 10.1109/IEEESTD.2017.8106924.

- “IEEE Standard Test Procedure for Thermal Evaluation of Insulation Systems for Liquid-Immersed Distribution and Power Transformers,” in IEEE Std C57.100-2011 (Revision of IEEE Std C57.100-1999) , 1-37, 2012, doi: 10.1109/IEEESTD.2012.6143968.

- B. A. Thango, J. A. Jordaan and A. F. Nnachi, “Service Life Estimation of Photovoltaic Plant Transformers Under Non-Linear Loads,” 2020 IEEE PES/IAS PowerAfrica, Nairobi, Kenya, 1-5, 2020, doi: 10.1109/PowerAfrica49420.2020.9219912.

- X. Chendong, Monitoring Paper Insulation Ageing by measuring Furfural Contents in Oil, 7th International Symposium on High Voltage Engineering, 26 – 30, 1991.

- A. De Pablo, Interpretation of Furanic Compounds Analysis – Degradation Models, CIGRE WG D1.01.03, former WG 15-01, Task Force 03, 1997.

- M. Dong, Z. Yan and G. J. Zhang, “Comprehensive diagnostic and aging assessment method of solid insulation in transformer,” 2003 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Albuquerque, NM, USA, 137-140, 2003, doi: 10.1109/CEIDP.2003.1254813.

- R. D. Stebbins, D. S. Myers and A. B. Shkolnik, “Furanic compounds in dielectric liquid samples: review and update of diagnostic interpretation and estimation of insulation ageing,” Proceedings of the 7th International Conference on Properties and Applications of Dielectric Materials (Cat. No.03CH37417), Nagoya, Japan, 3, 921-926, 2003, doi: 10.1109/ICPADM.2003.1218572.

- C. Lin, Bide Zhang, Yuchun Yuan, “The Aging Diagnosis of Solid Insulation for Oil-Immersed Power Transformers and Its Remaining Life Prediction”, 2010 Asia-Pacific Power and Energy Engineering Conference, DOI:10.1109/APPEEC.2010.5449486.

- M. K. Pradhan and T. S. Ramu, “On the estimation of elapsed life of oil-immersed power transformers,” in IEEE Transactions on Power Delivery, 20 (3), 1962-1969, 2005, doi: 10.1109/TPWRD.2005.848663.

- WG. D1.01, “Furanic Compounds for diagnosis”, cigré, Electra, 4, 2012, doi: ELT_261_06-furanic-compounds-for-diagnosis.

- R. A. Abd El-Aal, K. Helal, A. M. M. Hassan and S. S. Dessouky, “Prediction of Transformers Conditions and Lifetime Using Furan Compounds Analysis,” in IEEE Access, 7, 102264-102273, 2019, doi: 10.1109/ACCESS.2019.2931422.

- H. Shertukde, Distributed Photovoltaic (DPV)-Grid Transformer Applications, CRC Press, 2017, doi: Distributed-Photovoltaic-Grid-Transformers/Shertukde/p/book/9781138073845.

- Wai Yie Leong, Yuan Zhi Leong, Wai San Leong, "Energy Management Policy and Strategies in ASEAN", Advances in Science, Technology and Engineering Systems Journal, vol. 9, no. 4, pp. 102–109, 2024. doi: 10.25046/aj090411

- WaiYie Leong, LeeSun Heng, YuanZhi Leong, "Malaysia’s Renewable Energy Policy and its Impact on ASEAN Countries", Advances in Science, Technology and Engineering Systems Journal, vol. 9, no. 2, pp. 67–73, 2024. doi: 10.25046/aj090208

- Afrodite Papagiannopoulou, Chrissanthi Angeli, "Social Media Text Summarization: A Survey Towards a Transformer-based System Design", Advances in Science, Technology and Engineering Systems Journal, vol. 8, no. 6, pp. 26–36, 2023. doi: 10.25046/aj080604

- Saidi Mohamed, Habib Cherif, Othman Hasnaoui, Jamel Belhadj, "Design and Comparative Analysis of Hybrid Energy Systems for Grid-Connected and Standalone Applications in Tunisia: Case Study of Audiovisual Chain", Advances in Science, Technology and Engineering Systems Journal, vol. 8, no. 3, pp. 144–153, 2023. doi: 10.25046/aj080316

- Ayed Banibaqash, Ziad Hunaiti, Maysam Abbod, "Challenges Facing Solar Panel Energy Deployment within Qatari Homes and Businesses", Advances in Science, Technology and Engineering Systems Journal, vol. 8, no. 2, pp. 38–43, 2023. doi: 10.25046/aj080205

- Othmani Mohammed, Lamchich My Tahar, Lachguar Nora, "Power Management and Control of a Grid-Connected PV/Battery Hybrid Renewable Energy System", Advances in Science, Technology and Engineering Systems Journal, vol. 7, no. 2, pp. 32–52, 2022. doi: 10.25046/aj070204

- Bonginkosi Allen Thango, Jacobus Andries Jordaan, Agha Francis Nnachi, "Assessment of Transformer Cellulose Insulation Life Expectancy Based on Oil Furan Analysis (Case Study: South African Transformers)", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 6, pp. 29–33, 2021. doi: 10.25046/aj060605

- Bonginkosi Allen Thango, Jacobus Andries Jordaan, Agha Francis Nnachi, "Service Lifetime Loss Evaluation Method for Transformers Exclusively Serving Solar Power Plants", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 6, pp. 22–28, 2021. doi: 10.25046/aj060604

- Dilyana Gospodinova, Peter Dineff, "Impact Assessment of the Renewable Energy Sources Implementation in Bulgarian Single-Family Houses on the Greenhouse Gas by HOMER Pro Software", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 5, pp. 362–368, 2021. doi: 10.25046/aj060541

- Hsuan-Yu Kuo, Jau-Jr Lin, "Development of Miniaturized Monolithic Isolated Gate Driver", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 5, pp. 177–184, 2021. doi: 10.25046/aj060520

- Bonginkosi Allen Thango, Jacobus Andries Jordaan, Agha Francis Nnachi, "A Novel De-rating Practice for Distributed Photovoltaic Power (DPVP) Generation Transformers", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 4, pp. 154–160, 2021. doi: 10.25046/aj060418

- Bonginkosi Thango, Jacobus Jordaan, Agha Nnachi, "Peculiar Stray Gassing Occurrences in Solar Photovoltaic Transformers during Service", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 3, pp. 131–136, 2021. doi: 10.25046/aj060315

- Nganyang Paul Bayendang, Mohamed Tariq Kahn, Vipin Balyan, "Power Converters and EMS for Fuel Cells CCHP Applications: A Structural and Extended Review", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 3, pp. 54–83, 2021. doi: 10.25046/aj060308

- Kakoma Chilala Bowa, Mabvuto Mwanza, Mbuyu Sumbwanyambe, Kolay Ulgen, Jan-Harm Pretorius, "Assessment of Electricity Industries in SADC Region Energy Diversification and Sustainability", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 2, pp. 894–906, 2021. doi: 10.25046/aj0602102

- Oumaima Taki, Kaoutar Senhaji Rhazi, Youssef Mejdoub, "A Study of Stirling Engine Efficiency Combined with Solar Energy", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 2, pp. 837–845, 2021. doi: 10.25046/aj060297

- Bonginkosi Allen Thango, Jacobus Andries Jordaan, Agha Francis Nnachi, "A Novel Approach for Evaluating Eddy Current Loss in Wind Turbine Generator Step-Up Transformers", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 2, pp. 488–498, 2021. doi: 10.25046/aj060256

- Bonginkosi Allen Thango, Jacobus Andries Jordaan, Agha Francis Nnachi, "Application of Polynomial Regression Analysis in Evaluating the Techno-Economic Performance of DSPV Transformers", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 2, pp. 458–463, 2021. doi: 10.25046/aj060252

- Carol Dineo Diale, Mukondeleli Grace Kanakana-Katumba, Rendani Wilson Maladzhi, "Ecosystem of Renewable Energy Enterprises for Sustainable Development: A Systematic Review", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 1, pp. 401–408, 2021. doi: 0.25046/aj060146

- Abdurazaq Elbaz, Muhammet Tahir Güneşer, "Optimal Sizing of a Renewable Energy Hybrid System in Libya Using Integrated Crow and Particle Swarm Algorithms", Advances in Science, Technology and Engineering Systems Journal, vol. 6, no. 1, pp. 264–268, 2021. doi: 10.25046/aj060130

- Marcel Nicola, Marian Duță, Maria-Cristina Nițu, Ancuța-Mihaela Aciu, Claudiu-Ionel Nicola, "Improved System Based on ANFIS for Determining the Degree of Polymerization", Advances in Science, Technology and Engineering Systems Journal, vol. 5, no. 6, pp. 664–675, 2020. doi: 10.25046/aj050680

- Vikas Anand Vatul, Arputha Aravinth, Narayanan K, Gulshan Sharma, Tomonobu Senjyu, "A Novel Demand Side Management by Minimizing Cost Deviation", Advances in Science, Technology and Engineering Systems Journal, vol. 5, no. 5, pp. 262–268, 2020. doi: 10.25046/aj050532

- Amar Choudhary, Deependra Pandey, Saurabh Bhardwaj, "Overview of Solar Radiation Estimation Techniques with Development of Solar Radiation Model Using Artificial Neural Network", Advances in Science, Technology and Engineering Systems Journal, vol. 5, no. 4, pp. 589–593, 2020. doi: 10.25046/aj050469

- Katleho Moloi, Yskandar Hamam, Jacobus Andries Jordaan, "A Support Vector Machine Based Technique for Fault Detection in A Power Distribution Integrated System with Renewable Energy Distributed Generation", Advances in Science, Technology and Engineering Systems Journal, vol. 5, no. 4, pp. 577–588, 2020. doi: 10.25046/aj050468

- Ogbuefi Uche Chinweoke, Ene Princewill Chigozie, Kenneth Chijioke Chike, "Evaluation of Mini-Hydro Power for Off Grid Electrification in Rural/Isolated Areas in Africa", Advances in Science, Technology and Engineering Systems Journal, vol. 5, no. 2, pp. 703–710, 2020. doi: 10.25046/aj050287

- Zulmandakh Otgongerel, Gaemyoung Lee, Ankhzaya Baatarbileg, "The Capacity Factor of Renewable Energy Power Plants During Electric Power Peak Times in Jeju Island", Advances in Science, Technology and Engineering Systems Journal, vol. 5, no. 2, pp. 545–550, 2020. doi: 10.25046/aj050268

- Ahmed Elsayed ELGebaly, Mohamed Kamal El-Nemr, "Optimized Design of PM Halbach Array Linear Generator for Sea Wave Energy Converters Operate at Maximum Power Transfer", Advances in Science, Technology and Engineering Systems Journal, vol. 4, no. 4, pp. 440–448, 2019. doi: 10.25046/aj040453

- Tatjana Šimović, Mislav Gazdović, "Automation System for Regulation Optimization in Power Transformer Design", Advances in Science, Technology and Engineering Systems Journal, vol. 4, no. 1, pp. 1–7, 2019. doi: 10.25046/aj040101

- Italo Fernandes, David Melo, Gabriel Santana, Fernando Brito, Allisson Almeida, "Prospects of Wind Energy Injection in the Brazilian National Interconnected System and Impacts Analysis Through a Quasi-Steady Power Flow", Advances in Science, Technology and Engineering Systems Journal, vol. 3, no. 6, pp. 185–189, 2018. doi: 10.25046/aj030624

- Gints Poiss, Sandra Vitolina, Janis Marks, "Development of Indicators for Technical Condition Indexing of Power Transformers", Advances in Science, Technology and Engineering Systems Journal, vol. 3, no. 1, pp. 148–154, 2018. doi: 10.25046/aj030118

- André Richter, Ines Hauer, Martin Wolter, "Algorithms for Technical Integration of Virtual Power Plants into German System Operation", Advances in Science, Technology and Engineering Systems Journal, vol. 3, no. 1, pp. 135–147, 2018. doi: 10.25046/aj030117

- Claudio Busada, Hector Chiacchiarini, Sebastian Gomez Jorge, Favio Mengatto, Alejandro Oliva, Jorge Solsona, German Bloch and Angelica Delgadillo, "Control of a three-stage medium voltage solid-state transformer", Advances in Science, Technology and Engineering Systems Journal, vol. 2, no. 6, pp. 119–129, 2017. doi: 10.25046/aj020615

- Karel Octavianus Bachri, Bambang Anggoro, Arwin Datumaya Wahyudi Sumari, Adang Suwandi Ahmad, "Cognitive Artificial Intelligence Method for Interpreting Transformer Condition Based on Maintenance Data", Advances in Science, Technology and Engineering Systems Journal, vol. 2, no. 3, pp. 1137–1146, 2017. doi: 10.25046/aj0203143

- Chengjian Lian, Daming Zhang, "Electromagnetic Field and Lumped Circuit Analysis of Planar Transformer at Medium Frequency for Converter Application", Advances in Science, Technology and Engineering Systems Journal, vol. 2, no. 3, pp. 878–883, 2017. doi: 10.25046/aj0203109

- Ali Algaddafi, "Stand-alone Inverter: Reviews, Models and Tests the exist system in Term of the Power Quality, and Suggestions to Design it", Advances in Science, Technology and Engineering Systems Journal, vol. 1, no. 5, pp. 34–41, 2016. doi: 10.25046/aj010507