Characterization of Gum Arabic in Concrete Mix Design

Volume 6, Issue 2, Page No 262-266, 2021

Author’s Name: Ali Eltom Hassaballa1,2,a), Muneeb Yaslam Qabban1, Atif Ali Madkhali1

View Affiliations

1Department of Civil Engineering, Jazan University, Jizan, 82511, Saudi Arabia

2Department of Civil Engineering, Sudan University of Science and Technology, Khartoum, 11115, Sudan

a)Author to whom correspondence should be addressed. E-mail: tomali99@yahoo.com

Adv. Sci. Technol. Eng. Syst. J. 6(2), 262-266 (2021); ![]() DOI: 10.25046/aj060229

DOI: 10.25046/aj060229

Keywords: Gum Arabic, Setting Time, Workability, Compressive Strength

Export Citations

The present work focuses on the effect of adding gum Arabic on the setting time of cement pastes, workability, and compressive strength of concrete. For workability and compressive strength liquid gum Arabic was added to concrete mixes at ratios of 0.0% (control mix), 0.3%, 0.5%, 0.7% of the weight of cement. In addition, from 0.1% to 0.7%, ratios of GA were added to cement paste to investigate the effect of this admixture on the initial and final setting time of cement. Concrete cube specimens cast using metallic molds measuring 150 x 150 x 150 mm, and cured at 7, 28 and 91 days. From the results obtained it has been shown that the setting time of cement paste delays with increasing GA ratios. The amount of slump of fresh concrete increases largely with increasing GA ratios. GA develops considerably more compressive strength than normal concrete. The highest strength was observed at 7% of GA at all ages.

Received: 10 December 2021, Accepted: 23 February 2021, Published Online: 10 March 2021

1. Introduction

Some chemical admixtures are very expensive and liable to damage while bad storage. So, the major problem in the use of chemical admixtures is the high prices, leading to increased project costs and are therefore fewer corporate profits as a result. Researchers began to think to solve this problem through experiments on local materials and cheap price and study the possibility of use as a cheap admixture such as Gum Arabic. Gum Arabic may have water-reducing properties and a dispersing effect and has been used as pumping aids [1]. Welan gum, which is in the same class as Gum Arabic, has been reported to increase cohesiveness [2].

Gum Arabic is soluble in water, edible, and used primarily in the food industry and soft- drink industry as a stabilizer. The gum contains an oxidizing enzyme that may affect the preparation containing formulations that are easy to oxidize. The moisture content facilitates the dissolution of both carbohydrates combined with water and protein not bound with water in Gum Arabic solution [3]. According to Standard Association of Australia (SAA), pumping aids admixtures can be classified through natural gums, which are soluble in water [4].

2. Literature Review

Previous studies have shown the effects of different types of gum Arabic in concrete mixes; such as: [5], presented a paper on Arabic gum biopolymer (AGB) focusing on the impact of added AGB on the setting time, durability of concrete, and workability. They further performed X-ray fluorescence tests on cement-AGB mix powder for determining its chemical structure for estimating carbonation depth in AGB concrete samples for evaluating durability. The findings of this study indicated that initial setting time and fluidity of the AGB mortar elevate progressively with AGB content to a maximum weight fraction of 0.9% AGB. On the contrary, the increase in AGB dosage proportions was because of the slight reduction in density.

The Effects of Gum Arabic (GA) Admixture on the Mechanical Strengths of Cement Paste and Concrete using various ratios of GA as percentages of cement weight was investigated [6]. Content was taken as 420 kg/m3 with ratio of 0.5, to produce cement pastes and concrete specimens that were cured for 90 days in water. The research concluded that GA delayed the setting time of concrete and increased the compressive and flexural strength of concrete.

The impact of Gum from Acacia Karroo (GAK) as a retarding admixture in cement pastes was investigated [7]. The researchers compared compressive strength of cement mortars with 0.7, 0.8, and 0.9% weight of cement and w/c ratio of 0.5 were compared to those with (w/c) ratio of 0.44 but dosage of GAK. They also prepared concrete samples using higher dosages of GAK (1, 2 and 3% wt of cement) and a water bidder (w/b) of 0.61 and compared to those having the dosage but w/b ratio was reduced.

Similarly, in [8], the author studied the effect of GAK as a Water-Reducing Admixture in Concrete. Different ratios of GAK were employed for studying a slump test, density, and compressive strength. The findings of this study indicated that slump elevated by 200% at a 2% dosage of GAK, which facilitate reduction of water-to-binder ratio from 0.61 to 0.48 with a 3% dosage for samples. Reduction in w/b resulted in increased compressive strength of 37.03% above the control after 180 days of curing for a 3% dosage. The study concluded that Gum from GAK is utilized in concrete as a water-reducing admixture in order to produce greener and sustainable concrete.

There was a study on effect of Gum extraction from trees on mechanical properties of concrete was conducted [9]. The study presented the concrete strength determination with gum as a natural admixture using dosages of 0.5%-1%, wt% by cement. Gum Arabic, Badam gum, Tragacanth gum and Neem gum were used. Cube specimens of size 100mm*100mm*100mm size were casted and water cured for 7, 28 and 56 days. It was found that maximum compressive strength was achieved when using 0.5 % of Badam gum.

A study of using liquid gum instead of solution of sodium silicate as adhesive material to improve cold bonding strength was prepared. This study resulted in cold bonding strength more than 1.38MPa. in [11], the author investigated the impact of partial removal of cement with Neem Gum for determining the strength attributes of high-performance concrete and added to concrete mixes at various ratios (0.1%, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%,1.2% & 1.5%) by weight of cement content. The paper concluded that when using Neem gum in the form of powder, the compressive strength was slightly reduced with an elevation in the ratio of Neem gum in concrete mixes at ages 7, 21 and 28. On the contrary, high compressive strength concrete with better workability was shown through modified gum in its liquid state.

A research to evaluate balling in sisal reinforced concrete using gum Arabic, known for increasing the workability of plain concrete was presented [12]. Performance of two categories of 100 mm concrete cube specimens were considered, comprising control mix of 1:2:4 sisal fiber-reinforced concrete with 3% volume fraction (Vf) of the fiber cut into 30 mm length and gum Arabic of 0.2%, 0.4%, 0.6%, and 0.8% the weight of cement. Water/cement ratio was fixed at 0.6. The concrete cube specimens were cured at 7, 14 and 28 days. It is found that the addition of 0.8% gum Arabic by weight of cement to sisal reinforced concrete decreases balling, improves the workability of concrete mix and increases the strength of the concrete. Use of gum Arabic (acacia seyal) as concrete admixture was conducted [13]. This study aims at finding alternative indigenous Sudanese material for a concrete admixtures that are necessary for casting concrete in hot weather of the Sudan. The European standards BS EN 934 & BS EN 480 have been used as a paradigm to classify TG functionality as concrete admixture. water/cement ratio(W/C) of 0.58 and consistence (slump=70±10) mm were adopted. The 0.8%TG by cement weight has been found to be the most appropriate dosage with water reduction levels of 11.5% and 7.5%. Also, TG satisfied all criteria set by BS EN 934-2:2009 for a set accelerating water reducer (SA\WR). In [14], the author presented a conference paper on the suitability of Gum Arabic in terms of its competence for acting as a plasticizer in concrete for producing self-compacting concrete.

3. Aims and Objectives

This paper aims to investigate the effects of gum Arabic on the setting time of ordinary Portland cement and the properties of fresh and hardened concrete. GA is used herein as an alternative indigenous material for concrete admixtures that are necessary for casting concrete in hot weather of Kingdom of Saudi Arabia (KSA).

There is a dire need for using admixtures, specifically in Saudi Arabia, that have certain modified characteristics of concrete with respect to being well-suited with Saudi climatic conditions. For instance, there is an instant loss of workability because of high evaporation of mixing water, and the tendency adds more water to the mixture when concrete is mixed at increased temperatures. It should be noted that chemical admixtures can be utilized for elevating workability regardless of elevating the extent of mixing water. Therefore, there is a pre-requisite for developing natural, environmentally friendly, and inexpensive admixtures. This study tests the effect of Gum Arabic on the mechanical characteristics of concrete. A slump test, air entrainment, and compressive strength were conducted for determining concrete performance at different dosages and water-to-binder ratios.

4. Materials and Testing Procedure

The raw materials used in this research include cement, fine aggregate, coarse aggregate, water and gum Arabic (GA). Ordinary Portland Cement, meeting the specification of ASTM C 1437 [15], was used in this work.

The raw gum was processed into mechanically ground form; where 50 kg of the grinded gum was processed in the fluid bed drier machine for acquiring granulated form. The process of granulation was followed by a protocol to perform the procedure of granulation. The machine was programmed to have a temperature range of 400°C outlets and 7°C inlet while spraying of 300 mL of water per minute. The process was recurrent in a frequency of five times every 10 min.

Natural fine aggregate and crushed stone coarse aggregate meeting the requirements of ASTM C 33 [16] were used. The maximum size of course aggregate was 20 mm. The slump test was carried out immediately after mixing concrete for all samples. The compressive strength test of concrete cubes was carried out for 7, 28 and 91 days of age. Liquid gum Arabic was added at ratios of 0.0% (control mix), 0.3%, 0.5% and 0.7% by the weight of cement. This was conducted for finding the effect of Gum Arabic on the characteristics of slump test and compressive strength concrete. Concrete cubes were cast using metallic molds measuring 150 x 150 x 150 mm.

Figure 1: Unprocessed Gum Arabic

Figure 1: Unprocessed Gum Arabic

Figure 2: Processed Gum Arabic

Figure 2: Processed Gum Arabic

All concrete specimens were prepared through ordinary Portland cement (grade 52.5 MPa) mixed with 25% unclassified fly ash. Pretoria Portland cement donated all of the cement and fly ash. The composition of cement and fly ash was determined through X-ray fluorescence.

5. Concrete Mix Design

Concrete mix design for this work was prepaid according to American Concrete Institute (ACI-211.1) [17]. The constituents of this mix, the ratios and quantities of GA are shown in Table (1).

Table 1: Concrete mix design constituents

| Weight (kg/m3) | Constituents | ||

| 7.785 | Cement | ||

| 3.42 | Water | ||

| 8.46 | Fine aggregate | ||

| 15.75 | Coarse aggregate | ||

| 0.054 | 0.039 | 0.023 | GA (%): (0.3, 0.5 & 0.7) |

| 35.47 | 35.45 | 35.44 | Total |

6. Results and Discussion

6.1. Consistency and setting time of cement paste

Table (2) shows the results of the physical properties of ordinary Portland cement used in this paper, without adding GA (control sample) [15]. This table shows that the control sample is in conformity with the standard.

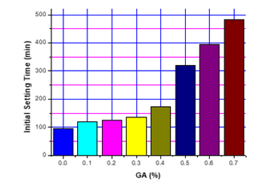

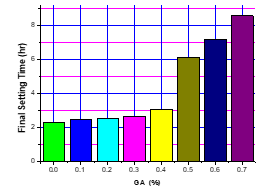

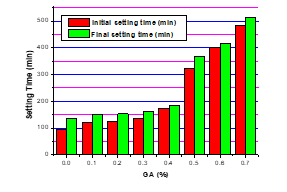

Table (3) shows the results of the initial and final setting time of cement paste by adding different ratios of GA. Results show that the measured initial setting time depends on the dosage of GA percentage as presented in Figure (3). There is a slight increase in initial setting time at the ratios of GA ranging from 0.0 % to 0.3% and then large increases starting from 0.4% to 0.7% of GA as shown clearly in Figure (4). The final setting time also changes in the same manner as in initial setting time. It increases with increasing of GA dosages as shown in Table (3) and Figure (4). For the delay in initial setting time GA can be used as an admixture in hot weather and as reducing water admixture in concrete mixes.

On the contrary, it should be noted that this is a type of false setting that has been excluded by re-mixing. It might be because of the hydrophilic nature of GA that adsorbs water with high affinity, but issue it at the time of re-mixing. Similarly, it did not influence the final setting time as retarded it by 7 minutes.

Table 2: Results of physical tests of cement paste (control mix)

| No | Test | Results | ASTM C150 |

| 1 | Standard consistency of cement paste (water %) | 25% | 25% -33% |

| 2 | Standard of cement paste reading (Vicat apparatus) (mm) | 34 | 33 – 35 |

| 3 | Initial setting time (min) | 95 | Not less than 45 min |

| 4 | Final setting time (min) | 149 | Not more than 375 min |

| 5 | Fineness % | 2% | Not more than 10% |

Table 3: Initial and final setting time of cement pastes using different ratios of GA

| No | GA (%) | Initial setting time | Final setting time | ||

| (min) | (hr) | (min) | (hr) | ||

| 1 | 0.0 | 95 | 1.58 | 137 | 2.28 |

| 2 | 0.1 | 120 | 2 | 149 | 2.48 |

| 3 | 0.2 | 124 | 2.07 | 153 | 2.55 |

| 4 | 0.3 | 136 | 2.27 | 160 | 2.67 |

| 5 | 0.4 | 174 | 2.9 | 184 | 3.07 |

| 6 | 0.5 | 321 | 5.35 | 367 | 6.12 |

| 7 | 0.7 | 483 | 8.05 | 514 | 8.57 |

Figure 3: Initial setting time of cement pastes using different ratios of GA

Figure 3: Initial setting time of cement pastes using different ratios of GA

Figure 4: Final setting time of cement pastes using different ratios of GA

Figure 4: Final setting time of cement pastes using different ratios of GA

Figure 5: Initial and final setting time of cement pastes using different ratios of GA

Figure 5: Initial and final setting time of cement pastes using different ratios of GA

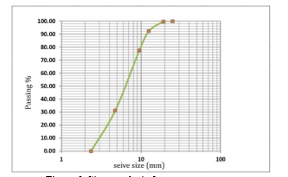

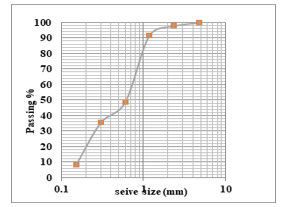

6.2. Sieve analysis for fine and coarse aggregate

Grading coarse and fine aggregate was determined by a sieve analysis (ASTM C33) [16]. From sieve analysis the fineness modulus (FM) of sand was found to be 2.2, which fell within 2.2 –2.6, which is categorized as fine sand fineness [17]. (FM=2.2) was used in estimating proportions coarse and fine aggregate in concrete mixture. Grading results for fine and coarse aggregates are shown in Figures (6 and 7).

Figure 6: Sieve analysis for coarse aggregate

Figure 6: Sieve analysis for coarse aggregate

Figure 7: Sieve analysis for fine aggregate

Figure 7: Sieve analysis for fine aggregate

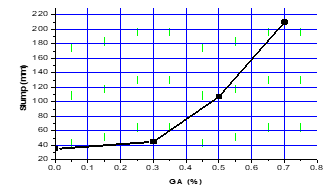

6.3. Results of slump tests

The result of slump tests is shown in Table (2) and graphically in Figure (5). Generally, it has been shown that slump increases with increasing GA ratios. At a 0.3% dosage, there was a considerable increase in the slump of 28.5% compared to the control. At 0.5% gum Arabic, the slump increased to 107 mm, while at 0.7% gum Arabic, slump recorded was 210 mm, thus indicating increase of 205.7% and 500% respectively when compared to the slump of the control mix.

It is worth noting that the dosage of 0.7% of GA mix showed considerable level of bleeding. Also, it was observed that for concrete mixes containing 0.7% of GA dosage the cubes demolding required two days.

Table 4: Results of slump tests using different ratios of GA

| GA (%) | Slump results (mm) |

| 0.0 | 35 |

| 0.3 | 45 |

| 0.5 | 107 |

| 0.7 | 210 |

Figure 8: Slumps (mm) using different ratios of GA

Figure 8: Slumps (mm) using different ratios of GA

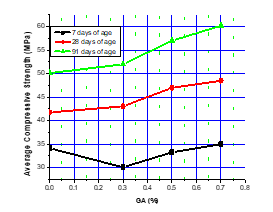

6.4. Results of compressive strength

Table (5) shows the average compressive strength of the concrete cubes taken at ages of 7, 28 and 91 days. There were large increases in strength when the dosages of GA and curing of samples were increased. The maximum strength was recorded at 0.7% of GA for all ages.

At low level dosages of 0.3% – 0.5% and for age of 7 days, there was a decrease in compressive strength compared to control mix. This was probably due to the fact that low dosages of GA with early ages of concrete GA have no significant effect on the properties of hardened concrete.

At a 0.7% dosage, strength increased significantly in all ages, probably due to the fact that this was the optimum dosage. At 0.7% of GA the differences in strength reached up to 2.6 %, 16.0% and 20%, for ages of 7, 28 and 91 days, respectively compared to control mix as shown in Figure (6).

The compressive strength of samples was enhanced through prolonged curing up to 91 days. On the contrary, the value of the control was not reached by this strength. At this age for samples, compressive strength varies between 7.3% – 11.5%. A compressive strength below the design mix of 34 MPa was yielded for samples treated with GAK at a w/b ratio of 0.61.

Nonetheless, the change in values between samples with different dosages was fewer than 5%. This might be because of the less effect of Gum Arabic at later age. This is a possible explanation because of the mitigation in the rate of cement hydration caused by the inclusion of Gum Arabic, reducing the dissolution of alkalis in the pore fluid [18]. Previous studies have indicated a reduction in compressive strength while using polysaccharide gums [19, 20].

Table 5: Results of Concrete compressive strength tests for ages of 7, 28 and 91 days using different ratios of GA

| GA (%) | Average Compressive Strength (MPa) | ||

| 7 days | 28 days | 91 days | |

| 0.0 | 34.13 | 41.746 | 50.10 |

| 0.3 | 30.09 | 43.065 | 52.00 |

| 0.5 | 33.28 | 46.997 | 57.00 |

| 0.7 | 35.02 | 48.499 | 60.20 |

Figure 9: Concrete compressive strength tests for ages of 7, 28 and 91 days using different ratios of GA

Figure 9: Concrete compressive strength tests for ages of 7, 28 and 91 days using different ratios of GA

7. Conclusion

In this paper, liquid gum Arabic was added to concrete mixes at ratios of 0.3%, 0.5%, 0.7% of the weight of cement in order to find out its effect on the properties of fresh and hardened concrete. From the results obtained it may be concluded that:

- The setting time of cement paste delays with increasing GA ratios which will make it an ideal plasticizer for concrete in situations where delayed setting time is required.

- The amount of slump of fresh concrete increases largely with increasing GA ratios.

- It was found that GA develops considerably more compressive strength than normal concrete. the highest strength was observed at 7% of GA at all ages.

- GA can be used in concrete as an admixture in hot weather and as a water reducing admixture in concrete mixes which is environmentally-friendly, thus producing sustainable and greener concrete.

- GA can be used as an admixture on the flexural and tensile strength as well as permeability of concrete for enhancing the performance of concrete in the construction sector.

Abbreviations

ACI American Concrete Institute

AGB Arabic gum biopolymer

FM Fineness Modulus

GA Gum Arabic

GAK Gum from Acacia Karroo

KSA Kingdom of Saudi Arabia

SA\WR Set accelerating water reducer

SAA Standard Association of Australia

Vf Volume fraction

W/C Water/cement ratio

Conflict of Interest

The authors of this paper hereby declare that no conflict of interest related to scientific research, direct or indirect financial relationships, employment, and personal beliefs exists.

Acknowledgement

The authors of this paper would like to express their appreciation to Scientific Research Deanship (SRD) of Jazan university for the financial support provided to this work. This research is a part of “future researcher’s program” funded by (SRD) under the code “FS10-084”. Authors’ gratitude is extended to department of civil engineering for kind assistance.

- American Concrete Institute. Specifications for Structural Concrete. Pumping Aids; ACI 301-05; ACI Education Bulletin, American Concrete Institute: Farmington Hills, MI, USA, 2005.

- M. Lachemi, K. M., Hossain, V. Lambros, P.-C. Nkinamubanzi, and N. Bouzoubaâ, “Self-consolidating concrete incorporating new viscosity modifying admixtures,” Cement and Concrete Research, 34,917–926,2004, doi.org/10.1016/j.cemconres.2003.10.024.

- P. A. Williams and G. O. Phillips, “Gum Arabic,” Handbook of Hydrocolloids, pp. 627–652, 2021.

- American Concrete Institute. Specifications for Structural Concrete. Pumping Aids; ACI 301-05; ACI Education Bulletin, American Concrete Institute: Farmington Hills, MI, USA, 2005.

- A. M. Mohamed, M. H. Osman, H. Smaoui, and M. A. Mohd Ariffin, “Durability and Microstructure Properties of Concrete with Arabic Gum Biopolymer Admixture,” Advances in Civil Engineering,2018, 1–9, 2018. https://doi.org/10.1155/2018/196283.

- A. Uchechukwu Elinwa, “Effects of Gum Arabic Admixture on the Mechanical Strengths of Cement Paste and Concrete,” Advancements in Materials, 1, 25, 2017, doi: 10.31058/j.am.

- R. Mbugua, R. Wanjala, and J. Ndambuki, “Influence of Gum Acacia Karroo on Some Mechanical Properties of Cement Mortars and Concrete”, World Academy of Science, Engineering and Technology, International Journal of Civil and Environmental Engineering, 9(11), 2015, doi.org/10.5281/zenodo.1109405.

- R. Mbugua, R. Wanjala, and J. Ndambuki, “Effect of Gum Arabic Karroo as a Water-Reducing Admixture in Concrete”, Materials 2016(9), 80, doi:10.3390/ma9020080.

- A. Deepthi, and K. P Kumari, “Study on Effect of Gum Extraction from Trees on Mechanical Properties of Concrete”, International Journal of Engineering Science and Computing (IJESC), ISSN 2321 3361, 9(11), 2019 IJESC, http://ijesc.org/.

- H. Hussein, “Improve Some Properties of Refractory Mortar Manufactured from Grog Bauxite, Attapulgite, Cao and white Cement by Using Gum Arabic”, International Journal of Civil Engineering and Technology (IJCIET), ISSN Print: 0976-6308 and ISSN Online: 0976-6316 10(03), 1308-1319, 2019. Article ID: IJCIET_10_03_127, http://www.iaeme.com/IJCIET/index.asp.

- M.G.L. Annaamalai, G. Maheswaran, R. Yuvaraja and R. Jayakodi, “Effect of Partial Replacement of Cement with Neem Gum on the Strength Characteristics of High-Performance Concrete”, International Journal of ChemTech Research, CODEN (USA): IJCRGG ISSN: 0974-4290 8(1), 178-183, 2015. www.sphinxsai.com.

- A.I.I. Dakas, S.E. Agboju and A.P. Enjugu, “The Effect of Gum Arabic on Sisal Fibre-Reinforced Concrete: Alternative Material for Prevention of Balling”, CARD International Journal of Engineering and Emerging Scientific Discovery. ISSN: 2536-7250 (Print): 2536-7269 (Online) 2(2), 2017. http://www.casirmediapublishing.com.

- S.A.L.A Satti and Y. H. Ahmed, “Use of Gum Arabic (Acacia Seyal) as Concrete Admixture”, 2nd Conference on Civil Engineering (CCE 2018), University of Khartoum, Sudan,.

- P.W. Zakka, O.F. Job and N.A. Anigbogu “Ecological Self-Compacting Concrete Using Gum Arabic as a Plasticizer”, In: Laryea, S. and Leiringer R. (Eds) Procs 6th West Africa Built Environment Research (WABER) Conference, 10-12 August 2015, Accra.

- American Society for Testing & Materials (ASTM C 150), 1999, Standard Test Method for Flow of Hydraulic Cement Mortar.

- ASTM C33-99a, Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates, ASTM International, West Conshohocken, PA, USA, 1999, http://www.astm.org.

- M.S. Shetty, “Concrete Technology- Theory and Practice”, S. Chand and Company Ltd., Ram Najar, New Delhi-110 055, 2005.

- F. Rajabipour, G. Sant, and J. Weiss, “Interactions between shrinkage reducing admixtures (SRA) and cement paste’s pore solution”, Cement and Concrete Research. 38(5), 606-615, 2008.

- L. Ma, Q. Zhao, C. Yao, and M. Zhou, “Impact of welan gum on tricalcium aluminate–gypsum hydration,” Materials Characterization, 64, 88–95, 2012, http://doi.org/10.1016/j.matchar.2011.12.002

- H. Y. Moon and K. J. Shin, “Evaluation on steel bar corrosion embedded in anti-washout underwater concrete containing mineral admixtures,” Cement and Concrete Research, 36, 521–529, 2006. https://doi.org/10.1016/j.cemconres.2005.09.014.