Waste To Energy Feedstock Sources for the Production of Biodiesel as Fuel Energy in Diesel Engine – A Review

Volume 6, Issue 1, Page No 409-446, 2021

Author’s Name: Maroa Semakulaa), Freddie Inambao

View Affiliations

University of KwaZulu-Natal, Mechanical Engineering department, Durban, 4041, South Africa

a)Author to whom correspondence should be addressed. E-mail: ssemakulamaroa@gmail.com

Adv. Sci. Technol. Eng. Syst. J. 6(1), 409-446 (2021); ![]() DOI: 10.25046/aj060147

DOI: 10.25046/aj060147

Keywords: Biodiesel Families, Sources of Biodiesel, Socio-Economic Opportunities Production and Utilization, Municipal Solid Waste, Waste to Energy

Export Citations

In the recent past, there has been a renewed shift into biomass and other recycled waste sources for biodiesel production and utilization. This is a critical area of research and study in which this present work intends to review and identify gaps in literature by shifting the focus of review to non-plant based sources for biodiesel production. Traditional biodiesel feedstock sources have always presented a conflict of food security versus energy. This shift will be identified in literature to see if change to non-plant based feedstocks sources has increased food security by discouraging the contribution of commercial farming for the production of biodiesel. This work will identify biodiesel families, generations, traditional and non-traditional feedstocks for biodiesel production. It will also discuss the non-edible biodiesel feedstocks sources in relation to waste to energy recovery. The other factor this work will review is to study how the use of non-plant based feedstocks such as municipal solid waste has improved environmental protection by reducing pollution and landfilling. In other words, this work will review the impact of Using waste municipal solid biomass resources such as waste tyres and waste plastics and changing them into energy sources. This review study aims at increasing environmental awareness, sustainability and reporting the progress made in waste to energy policy shift in many countries globally. This review will look at socio-economic opportunities in recycling besides the academic and research impacts of waste to energy policies adopted in many countries. The review will climax with a conclusion and future trends in waste to energy in relation to municipal solid waste resources.

Received: 28 September 2020, Accepted: 04 December 2020, Published Online: 22 January 2021

1. Introduction and Historical Background of Biodiesel

The history of biodiesel fuel has its route traced to the discovery of the diesel engine by the German engineer Rudolf Diesel in the 1890s. However, the first use of vegetable oil as a fuel was in the world exposition in Paris in 1900. This was at the request of the French government, which had an interest in development of fuels of local origin for its African colonies for energy and power generation independence. There were a total of 5 engine models displayed and tested during the exposition [1]. After the Second World War, several literatures report the use of vegetable oil in diesel engines and operational difficulties encountered with their application as combustion fuel [2-5].

These reports led to the award of the Belgium patent 422877 in 1937 to Chavanne. However, after the second world war the alternative fuel research took a lull until the energy crisis of the 1970s when [6] came up with work on esters of vegetable oil. Using sunflower oil in a diesel engine, they reported that use of sunflower methyl esters eliminated the problems of viscosity and operational issues. Although fossil-based fuels have been playing a major role in the growth of industries, transportation and agricultural activities, the future of fossil fuel as primary source of energy is not sustainable due to depletion, outstripped demand of fuel energy consumption and use. Fossil based fuel have more qualities that make them appeal to the user readily such as availability, good combustion properties and high heating values [7]. Energy estimates from the international energy agency puts the estimates of the growth of energy consumption at 53 % by the year 2030 [8, 9].

In the USA the energy information agency (EIA) projects liquid fuel consumption to increase from 86.1 million barrels per day to 110.6 MBD by the year 2035 [10]. The depletion of fossil fuel reserves has occupied world energy forums and decision makers. Therefore, there has been rapid research development in green alternative fuel energy, which is renewable, domestically available, environmentally friendly and feasible technically. Biodiesel therefore has become technically a better choice for researchers as they contain characteristics and identical physical properties to fossil fuel especially diesel fuel. This makes the future of biodiesel more tenable and more promising as sources of alternative fuel energy especially in developing countries. These countries experience a heavy burden on the importation of liquid petroleum fuel for energy, environmental impacts and effects of pollution on the public human health [11]. Table 1 showing a global production of biodiesel in 2015 and the unit cost of production.

Table 1: Worldwide production of biodiesel with cost [12]

| Country | Estimated potential (Litres) | Production Cost($/l) |

| Brazil | 2,567,000,000 | 0.62 |

| Indonesia | 7,595,000,000 | 0.49 |

| Argentina | 5,255,000,000 | 0.62 |

| Malaysia | 14,540,000,000 | 0.53 |

| USA | 3,212,000,000 | 0.85 |

| Netherlands | 2,496,000,000 | 0.75 |

| Germany | 2,024,000,000 | 0.79 |

| Philippines | 1,234,000,000 | 0.53 |

| Belgium | 1,213,000,000 | 0.78 |

| Spain | 1,073,000,000 | 1.71 |

The importance of modern-day transport systems cannot be gain said, especially the transportation of goods and services and people. The propulsion provided by internal combustion engines with diesel fuel as the primary source of energy, forms the bulk of commercial use and now personal transport, owing to their numerous advantages as compared to other forms or types of propulsion by internal combustion engines. Diesel engines are inherently lean burn engines, and emit relatively low carbon dioxide emissions as compared to petrol propelled internal combustion engines. Other advantages offered by diesel engines include high thermal efficiencies, durability and construction robustness [13]. This makes their continued increase and expansion as more countries move into urbanization, industrialization, and catching up with the highly industrialized countries. However, there has been a formidable challenge to phase them out, based on environmental and human health issues due to the high levels of NOX, smoke and PM emissions.

Diesel engines have shown to run stably on most medium blended ratios of waste plastic oil, although they produce more NOX, UHC and CO emissions. However to stabilize their performance for higher blend ratios, injection timing has been proposed as a method of achieving engine performance stability without upgrading of fuel, engine modification or fuel alteration through addition of additives as observed by [14]. Injection timing was seen to affect performance from WPPO Jatropa blends of 20% tyre oil and 80% Jatropa ester oil resulting into lower fuel consumption, CO, UHC and PM although NOX emissions increased [15]. Nevertheless In a research study by [16] the authors report increased BTE and NOX emissions, thus concurring with the findings of Sharma et al. (2015) on emissions of NOx, but decreased results on fuel consumption, CO, and UHC.

The continued increase in stringent emission regulations enacted by global industrial powers, United States of America and the European Union environmental protection agencies including the G-7 and G-20. Have since labelled the diesel engine as primary polluter in the transport sector. Hence the clamour for alternative fuels, which mitigate pollution, are sought in the interest of reducing energy consumption, environmental degradation and air pollution from NOX gases, which diesel engines emit, thus decelerating atmospheric carbon concentration globally. The road transport sector is an environmental concern, since its rapid expansion is fast eroding all the technological developments and improvements thus so far achieved in the war against pollution from diesel-propelled engines.

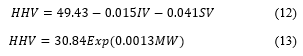

Across the globe, significant resources have been mobilized to find alternative sources of energy. Different regions and countries have focused attention at sources of supply and technical processes that give them comparative advantages. In sub-Saharan Africa, renewable energy alternatives for transportation have huge potential sources, one of which is biodiesel derived from municipal solid waste sites, waste tires, waste engine used oil and waste cooking oil. Considerable research has been ongoing in this area but some gaps have not been addressed. There is a clear need to conduct evaluations that enable precise technical classification of the performance and emission of biodiesel derived from the waste sources mentioned above. Figure 1 is showing available general waste data (from municipalities) in South Africa from 1997 to 2011.

This will enable us to filter the data, by comparing it with local South African standards and regulations with global standards and regulations. Through this, challenges can be identified and plans of action mapped out to tackle them. It is necessary to identify and assemble the right set of tools and technique needed to conduct studies on these municipal solid waste feedstock sources in a manner that optimizes them as available resources. The stated goal of this work is to extract, information on solid waste municipal sources for the production of biodiesel using thermal processes. This information is contained in many published research articles and will be presented here as a review and future development.

Figure 1: Percentage contribution of each waste stream of general solid Analysed from available data 2017 (from municipalities) in South Africa [17]

Figure 1: Percentage contribution of each waste stream of general solid Analysed from available data 2017 (from municipalities) in South Africa [17]

2. Biodiesel Families and Generations

Traditionally families come in generations defined by the length of time. As such, biofuels have lumped into families or generational categories. Production and use of biofuels has gained significant awareness and attention in academia, industry and government policy makers. Globally 28 countries including developing countries have been prominent in enacting biofuel mandated policies with substantial tax subsidies for biofuels [18]. Biofuels shift targets displacement of 20% of fossil fuels by biodiesel in the coming future [19].

This is driven in part by the potential of biofuels to create a new industry, raise farmer incomes restore degraded lands and promote independence from oil imports hence mitigating climate change [20]. For example, in literature, surveyed India is among the countries that have adopted Jatropa as a second-generation biofuel source of feedstock. However, in literature reviewed, there is no data on, water, pruning, and plant response to fertilizers hence varied planting management practices [21-23].

In biofuels, the main aim has been to identify methods of production by selecting appropriate feedstock, use of efficient conversion technologies and disposal of the product in this case the biofuels. The end product of any process in the world has become critical due to environmental issues and impact products bring, such biofuels production on the immediate environment [24]. One of the leading challenges in the energy sector is the promotion of biofuels compared to fossil fuels through arguments of sustainability i.e. economic environment and social aspects combined [25]. Sustainable development is a common term appearing in the global agenda of development since 1987. It is defined as development tailored to meet the needs of the present generations without compromising on the future generational needs in meeting today’s needs [26, 27]. Sustainability requires that all environmental factors of impact be assessed in each of their phases of the biofuels chain such as (i) Production and collection of feedstock, (ii) Feedstock processing, (iii) Conversion to biofuels, and (iv) Distribution of the end product [28, 29].

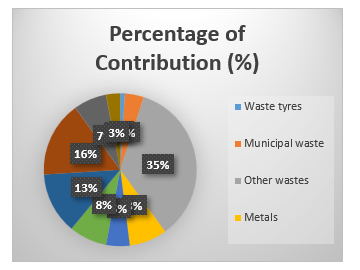

The second point is sustainability, which according to literature surveyed is difficult to conduct and evaluate sustainably. For example due to a great number of competing interests interfacing factors are weighted different by stakeholders hence disagreements and lack of common approach [28, 29]. Measuring sustainability of the biofuels industry is a complex issue especially considering the diverse range of biofuel feedstock, pathways, variation in stakeholder’s interests and competing interests. Literature surveyed thus advocates for establishment of other indicators, which will enable assessment of sustainability of bioenergy systems. This should apply to small, large and local infrastructure acceptable to all stakeholder and in diversity [30-32]. Figure 2 showing the interrelated pillars of sustainability between society, the environment and the economy.

Figure 2: Interrelated pillars of sustainability adapted from [25]

Figure 2: Interrelated pillars of sustainability adapted from [25]

2.1. First Generation Biofuels

First generation biofuels are derived from food crop feedstocks usually used as staple food. However, today this generation is vilified as the source of food insecurity and rising inflation in developing countries. Nevertheless, it is important to note even if it is alleged first generation cause increment in food prices and inflation its total influence is minimal [33]. First generation biofuels ( otherwise called conventional biofuels) use three different technologies commercially for biodiesel, bioethanol and biogas [34, 35]. These commercial fuels are utilized as solid, gaseous or as liquid fuels. To add value these fuels are upgraded to high-density energy fuels such as charcoal, liquid fuels such as biodiesel, and bioethanol or gaseous fuels such as hydrogen, natural gas or biogas [33]. Table 2 shows the characteristics and demerits of first-generation biofuels.

As a first generation, conventional fuel biodiesel is produced through transesterification of vegetable oil, residual oils and animal fats as alternatives for petroleum diesel with slight engine modifications. In the processing triglycerides are chemically reacted with alcohol in the presence of a catalyst or enzyme. This process generates biodiesel and glycerol [36, 37]. On the other hand, bioethanol are produced through a Biocatalytic fermentation of sugar or starch as ether (ETBE) which is used as a blend with gasoline. the gaseous category biogas a mixture of methane and carbon dioxide is processed through anaerobic digestion of organic materials [38, 39].

Table 2: Shows characteristics and demerits of first generation biofuels

| Characteristic | First generation biofuel | References |

| Completion with food crops | Made from edible oil and starch feedstock | [40] |

| Land footprint | Requires arable land | [41] |

| Conversion to biofuels | Easy conversion | [42] |

| Water footprint | Potable water is required for cultivation | [43, 44] |

| Environmentally friendly | Using pesticides and chemical fertilizers | [45] |

| Commercialization | Commercially produced | [40] |

| Sustainability | Not sustainable in using natural resources such as water and land | [46-48] |

| Nutrient requirement | Chemical Fertilizers as main nutrients | [49] |

| Harvesting | Done by hand or machine | [50] |

| Regulation | Clear fair regulation | [40, 51] |

| Financial input | Low capital investment | [40] |

| Environmental condition | Temperature and humidity must be suitable | [52] |

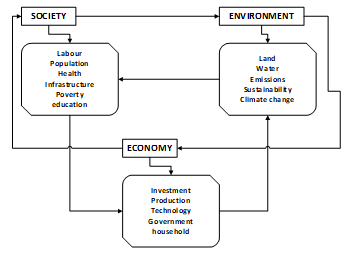

Despite their acceptance first generation, fuels have demerits, which have made their global appeal and wide commercial application difficult. For example, their overdependence on agricultural food crops initiates a heavy social debate on food vs fuel. Hence, their commercialization and adoption threaten food security while inflating food prices in developed countries. In semi-arid areas, production of biofuels would be too costly and limited with determined prices considered as non-competitive to conventional fuels. Figure 3 is showing different biofuel families and their available feedstocks sources.

2.2. Second Generation Biofuels

Second generation biofuels family is also called advanced biofuels. These fuels are also purported to be produced sustainably in a truly carbon neutral environment in terms of CO2 concentration. The source of feedstocks of these fuels is lignocellulosic biomass, non-food crops, agricultural and forest residues and industrial wastes. The production of second generation is done by utilizing physical, thermochemical and biochemical technologies processing [55, 56]. Using these processes involves use of pre-treatment steps to facilitate the conversion process. Here properties of biomass are technically analysed such as size, moisture and density before treatment and processing is commenced [57].

In physical processing techniques in literature reviewed, the commonly applied techniques are briquetting, pelletizing and fibre extraction. These techniques enhance and convert loose biomass into high density solidified blocks of energy. Pelleting does the same thing pressure does to compact raw fibre particles of biomass into high density. On the other hand in fibre extraction fibre is removed from biomass residues and utilized as sources of energy fuel for heating [55, 58].

Under thermochemical processes for production of biofuels are found pyrolysis, gasification liquefaction and direct biomass combustion. Thermochemical liquid fuel processing uses thermal decomposition with chemical reformation. This involves heating biomass under the influence of different oxygen concentration leading to conversion of all organic components [39]. Pyrolysis is a slow or fast process depending on the existing operating conditions but in the absence of air [59, 60]. The former favours solid fuel production compared to the latter which is good for liquid fuel production (bio-oils) and gaseous biofuel production [61, 62].

Figure 3. showing different biofuel families and their feedstocks [53, 54]

Figure 3. showing different biofuel families and their feedstocks [53, 54]

As a method in second-generation biofuels, gasification coverts biomass into combustible gaseous fuel mixtures also known as syngas. Through partial oxidation of biomass at elevated temperatures of 800 ℃ to 1400 ℃ syngas is produced. The medium for gasification can be air oxygen of steam [55, 60]. However gasification is still struggling with challenges of operational and downstream gas utilization problems [63]. The driver of gasification has been the versatility of the gases produced during the process. Reaction of the gasification and the feedstocks of solid carbon structure forms carbon dioxide or hydrocarbons. Nevertheless, as said earlier the gasfying agent has a very critical role in influencing the final product of the process. For example when steam is used as an agent of processing reaction temperatures are lowered to 600℃ [39]. Table 3 is showing the principle components of a gasification process.

Table 3: is showing the principle components of a gasification process adapted from [63]

| Target compounds | CO, H2, CH4, C2Hx, C3Hx |

| ‘Inert’ (non-combustible) compounds | CO2, H2O, (N2) |

| Trace contaminants | NH3, HCN, other organic nitrogen compounds |

| H2S, COS, CS2, other organic sulfur compounds | |

| HCl, NaCl, and KCl aerosols | |

| Condensable fraction | Benzene, toluene, and xylene (BTX), tar, hetero-organics, (water) |

| Particles | Ash, mineral matter/salts, char, aerosols |

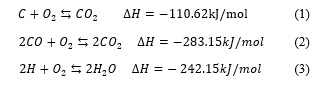

During transformation (conversion) of solid fuel into gaseous components by gasification a number of reactions with intermediate reactions, take place. It is a complex network of reactions; influenced by feedstock sources, and properties, residence time, reactor design temperature gasifying agent and pressure. In this literature review, only a few examples of main reactions are presented in chemical equations 1 to 9. However, the references provided here would be useful to the reader for a detailed study and understanding [39, 64-66]. Table 4 is third generation biofuels characteristics and references.

Chemical reactions with molecular oxygen, which are exothermic in nature (combustion reactions).

Carbon dioxide and hydrocarbon/CO2 reaction

Carbon dioxide and hydrocarbon/CO2 reaction

Boudouard reaction:

![]() Hydrocarbon and steam reaction:

Hydrocarbon and steam reaction:

![]() Water gas-shift reaction (homogeneous water-gas shift conversion)

Water gas-shift reaction (homogeneous water-gas shift conversion)

![]() Hydrogen reactions in gasification

Hydrogen reactions in gasification

2.3. Third Generation Biofuels

2.3. Third Generation Biofuels

The third generation biofuel family comprises of fuels produced from microalgae feedstocks. This generation is currently under research and development as alternative renewable energy sources for biofuel processing and production. This family has been largely been fronted as a solution to overturning the demerits of the first generation and second generation biofuels [55, 68]. Majority of these fuels exist in laboratories under research and development with a few small scale enterprises producing algae oil [69]. The microalgae group of feedstock consists of microalgae, macroalgae (seaweed) cyanobacteria (blue-green algae) [70]. Microalgae consists of 72000 different species and as many as 800000 in fresh water or salty water [69, 71].

Table 4: Shows characteristics and references of third generation biofuels

| Generational Characteristics | References |

| Eliminates food-energy conflict | [40] |

| Contaminated and Non-arable land used for cultivation | [41] |

| Easy conversion due to increased hydrolysis and/or fermentation efficiency | [42] |

| Waste, saline and non-potable water also can be used | |

| Merits (CO2 fixation, waste water treatment, reduced cost of fertilizer) demerits (ecological concerns on marine eutrophication ) | [43, 44] |

| Poor biomass production for commercialization | [45] |

| favorably poor economically | [40] |

| Large quantities of carbon and nitrogen required. Solar energy is only available at daytime. Nutrients recycling possible | [46-48] |

| Harvesting of microalgae is expensive, and complicated | [49] |

| Lack of regulation for marine cultivation | [50] |

| initial large scale cultivation costs too high | [40, 51] |

| cultivation in harsh environmental condition such high pH, salinity and light intensities possible | [52, 67] |

The rise of algae as an alternative biodiesel feedstock is due to its rapid growth, increased harvest cycle in days compared to months or years. Microalgae need few nutrients for maximum growth and can thrive in severe poor conditions while giving high and increased output per acre ranging from 15 to 300 times more compared to food crops acreage [72, 73]. Algae oil can also be used as feedstock to provide high value products such as ethanol, butanol, biodiesel, jet fuel syngas, and bio-oil chemical feedstocks such as hydrogen and farm fertilizers [53, 70].

Another important factor with algal biofuel is the lack of competition with food crops or feed crops, yet algae is used to reclaim agricultural wastelands. This seems to obviate and free land use while reducing energy versus food competition. This elevates this family against the first two-biofuel families. However a further research and study aimed at improving algae production methods especially the plant energy content yield and sustainability is required [54]. Table 5 shows different oil contents for a variety of microalgae species.

Table 5: Showing different Oil contents for a variety of microalgae adapted from [41]

| Microalga Oil content | Percentage in dry weight (%) |

| Botryococcus braunii | 25–75 |

| Chlorella sp. | 28–32 |

| Crypthecodinium cohnii | 20 |

| Cylindrotheca sp. | 16–37 |

| Dunaliella primolecta | 23 |

| Isochrysis sp. | 25–33 |

| Monallanthus salina | 20 |

| Nannochloris sp. | 20–35 |

| Nannochloropsis sp. | 31–68 |

| Neochloris oleoabundans | 35–54 |

| Nitzschia sp. | 45–47 |

| Phaeodactylum tricornutum | 20–30 |

| Schizochytrium sp. | 50–77 |

| Tetraselmis sueica | 15–23 |

2.4. Fourth Generation Biofuels Sources and Beyond

The birth of fourth generation biofuel has been propagated by the need arising from environmental dilemmas. These dilemmas challenge our human capacity for sustainable solutions to protect nature for our own existence and posterity. For example, the need to protect water sources, agricultural lands for sustainable food production, reduction of GHG, the protection of atmospheric air and weaning overreliance from fossil fuels as the only sources of primary energy supply [74-79]. Table 6 Showing characteristics and references of fourth generation biofuels.

Table 6: Characteristics and references of fourth generation biofuels

| Generational Characteristics | References |

| Eliminates the food-energy conflict | [40] |

| Contaminated and Non-arable land used for cultivation | [41] |

| Increased hydrolysis and/or fermentation efficiency | [42] |

| Waste, saline and non-potable water also can be used | [43, 44] |

| Offers Medium (CO2 fixation, waste water treatment) but releases GM organisms | [45] |

| Produces less biomass for commercialization | [40] |

| Leaking of GMO to environment pausing ecological risks | [46-48] |

| Large carbon and nitrogen required. (However, Solar energy is daytime). Requires Nutrients recycling in the process | [49] |

| Harvesting of microalgae is expensive, and complicated | [50] |

| No regulation for marine cultivation but strict regulation is required with GM algae | [40, 51] |

| Initial cost for large scale cultivation is expensive | [40] |

| Cultivation in harsh environmental condition possible (such as high pH, salinity high light intensities) | [52, 67] |

Fourth generation biofuels are oils therefore produced from genetically modified feedstocks able to consume more CO2 from the atmosphere than what they will produce during the combustion phase as fuels [80]. Therefore fourth generation fuel utilizes the existing platform technologies such as pyrolysis, gasification, solar to fuel and genetic manipulation of organism’s genetic order. The fourth-generation family is referred to as smart fuels based on the conversion of vegoil and biodiesel to biogasoline using advanced technology.

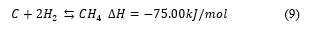

Despite large-scale production and efforts to try to commercialize this family progress has not been sufficient. This has been due to lack of sufficient biomass, increased production costs and set-up, environment and human health concerns as fewer feasibility studies have been completed [40]. Table 7 is showing health and environmental effects of fourth generation biofuels. While Figure 4 is showing main steps of algal biomass technologies in carbon fixation.

Table 7: The health- and environment-related risk of GM algae Human health [81, 82]

| Topic Risk contribution | Risk contribution | Effect | References |

| Allergies

|

Human health

|

Dermal, ingestive, respiratory exposure | [82-86] |

| Antibiotic resistance

|

Human health

|

Reducing the effectiveness of medical treatments | [84-86] |

| Carcinogens | Human health

|

Carcinogenic residues | [82] |

| Pathogenicity or toxicity | Environment | Pathogenicity of some strain to human; toxic blooms; chemical transfer; toxic residues | [82, 87, 88] |

| Change or depletion of the environment | Environment | Removal of nutrients from ecosystem; reducing biodiversity of the flora and fauna

|

[89, 90] |

| Competition with native species

|

Environment | Outcompete native organisms; changing aquatic ecosystems

|

[91, 92] |

| Horizontal gene transfer | Environment | Transfer of genetic organisms | [93, 94] |

| Pathogenicity or toxicity

|

Environment | Pathogenicity of some strain to human; algal blooms; generating genetic–related toxins

|

[95] |

Figure 4: Carbon dioxide fixation and main steps of algal biomass technologies adapted [80]

Figure 4: Carbon dioxide fixation and main steps of algal biomass technologies adapted [80]

GM crops have been with us since 1996 as sources of 3rd and 4th generation biofuels and have increased in their global acreage. For example soybeans, maize and rapeseed occupy 73.3 1013, 46.8 1013, and 7 103respectively of all global land mass area under cultivation [96, 97]. Nevertheless, in order to increase fourth generation biomass production of biofuels algae is heavily GM sourced. Which is achieved by improving areas of the micro-organism using genetic material engineering manipulation. For example, the following areas are mentioned in literature to engineer increased microalgal biofuel production. (i) Improvement of photosynthetic efficiency, (ii) Increasing light penetration by using the truncated chlorophyl antenna and (iii) Reduction of photo-inhibition.

Literature is averse with these developments in the literature reviewed and presented here such as [98-101]. The development in fourth generation biofuels also aims at providing new economic development opportunities in remote and suburban areas of developing countries. These opportunities include reduction of emission to zero for both air pollutants and GHG [102, 103].

Microalgae form a large group of eukaryotes and cyanobacteria and have a wide range of compositional characteristics which include; [104] Food reservation, Photosynthetic pigments, Cell wall chemistry and reproduction. However out of the many species of microalgae only Bacillanophyceae (diatoms), Eustigmatophyte, Chlorophyceae and Chrysophyceae are potential sources of biofuel production [105]. Microalgae have high adaptability in extreme environmental conditions such as high salinity, drought, photo oxidation, osmotic pressure, temperature, anaerobiosis and ultraviolet (UV) radiation [106]. Their main nutrients are nitrogen and phosphorous which accounts for 10% to 20% of its biomass [107, 108].

3. Biodiesel Feedstock Sources, Production, and Processing Techniques

3.1. Introduction to Edible Vegetable Oil and traditional Feedstocks

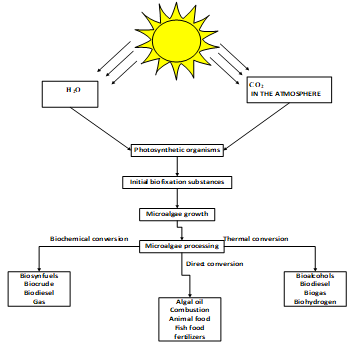

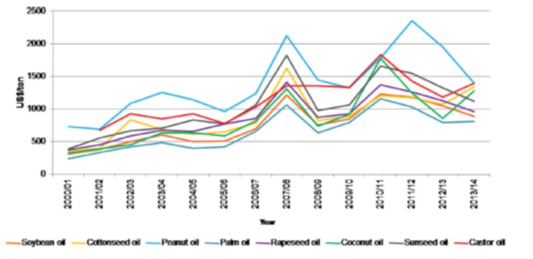

The production of biofuels such as biodiesel is becoming convenient as alternative energy. The use of biofuel such as biodiesel reduces GHG and provides opportunities for local and regional development in remote areas. This is made feasible considering the number of feedstocks sources. Biodiesel feedstock types differ from country to country depending on the geographical locations and their development [109, 110]. Globally more than 350 oil bearing crops have been identified [111] as possible biofuel feedstocks. However, there are many relevant candidates for biofuel production f eedstocks adding to the list but are non-plant based. Figure 5 is showing the growth in vegetable oil production in China from 2003 to 2015.

eedstocks adding to the list but are non-plant based. Figure 5 is showing the growth in vegetable oil production in China from 2003 to 2015.

Figure 5: China’s biofuel production over the past decade [112]

The advance in experimental biodiesel production from theses feedstocks has led to a waste to energy revolution. Biodiesel production from readily available feedstock considered waste candidates for dumping and landfill [113]. This has encouraged value addition and co-product markets while contributing to diversification of the biofuel industry [114]. Nevertheless, since each feedstock is different from the other the conversion and processing techniques vary but the basic process of production remains the same. The wide range of feedstocks availability plays a significant role in promoting the biofuel industry.

The availability of feedstocks is influenced by regional climate, geographical location, local soil characteristics and general agricultural practices of a region or country [115]. In sources of biofuel development production and processing, only sunflower, cottonseed, safflower, rapeseed and peanuts are considered compared to two, corn and sugarcane for bioethanol used in gasoline engines;. However, it is important to mention here that non-edible oil plants such as Karanja, rubber seed, tallow oil and microalgae, Jatropa and neem seeds are also gaining acceptance as alternative sources of biofuel. In the last decade, non-edible feedstocks have been extensively studied in literature surveyed such as [77, 116-118].

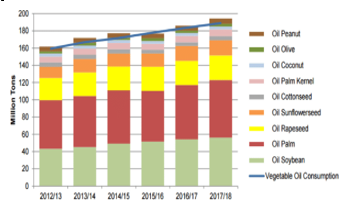

Among plant-based feedstocks palm oil, soybean and rapeseed account for almost 80 % of global feedstock for biofuel production as shown in Table 8. To qualify as a feedstock for biodiesel production the oil percentage and yield are important factors for consideration [119-122]. Nevertheless quality, availability, physicochemical properties, composition and production costs are some of other critical factors of feedstock determination and acceptability [119]. Feedstock prices account for more than 80% of the cost hence selecting and quality feedstock is vital to ensure low production costs [120, 123]. Since feedstocks are impacted by oil percentage yield, these factors are critical and need consideration. Figure 6 is showing total global vegetable oil production and production contribution of each source from 2013 to 2018. While Table 8 shows major vegetable oil producers and their main sources of feedstock respectively. On the other hand, Figure 7 is showing, international vegetable oil prices from 2000 to 2014.

Figure 6: Global vegetable oil production and consumption [124]

Figure 6: Global vegetable oil production and consumption [124]

3.2. Soybean Biodiesel Feedstocks

Soybean comes from the Glycinemax L. as a legume with an annual cycle from the Fabaceae family [130]. United states of America, Brazil and Argentina are the leading producers accounting for 80% of all global production [131]. However, china is increasing production and catching up, hence expanding its role in the near future considerably. It is important also to note that china imports almost 1/3 of the world’s production of soybean. This accounts for 62% of all global soybean trade [132]. Soybean as a grain contains 14% to 17% oil, 33% to 40% protein [133]. In the period of 2013 to 2015 soybean was responsible for over 65% of the global supply of protein supplements and feeds [134]. Soybean meal is the extraction obtained from the oil extraction process and one of the most important source of human and animal protein [135-138].

Table 8: Shows major vegetable oil producers and their main source of feedstock [12, 125-129]

| Country | Production (1000t) | Main feedstock |

| USA | 4.150 | Soybean (53%) |

| Brazil | 3.000 | Soybean (77%) |

| Germany | 3.000 | Rapeseed (>50%) |

| Indonesia | 2.750 | Palm oil (100%) |

| Argentina | 2.550 | Soybean (100%) |

| France | 1.850 | Rapeseed (>50%) |

| Thailand | 1.050 | Palm oil (77%) |

| Total Europe | 10.200 | – |

| Total world | 26.150 | – |

In addition soybean extracts are used in the textile and plastic industry as molds, glue or adhesives for laminated paper and wood [139]. Soybean is also the main raw material in the vegetable oil industry, whose production by 2012 exceeded 40 million tonnes representing 25% of global production of vegetable oils [140]. Environmentally soybean compared to fossil energy consumption over the biofuel life ranges from 2 MJ/MJ-1 to 8.5 MJ/MJ-1 [141-143]. On the other hand, comparatively its GHG life cycle varies from 8 gCO2e MJ-1 to 42 gCO2e MJ-1 of biodiesel [143]. However, in the literature surveyed only one researcher reported higher values of 50 gCO2e MJ-1 [142]. This was attributed to the assumption adopted during life cycle analysis hence the difference in the values of the findings [114].

Figure 7: International prices of vegetable oils from 2000 to 2014

Figure 7: International prices of vegetable oils from 2000 to 2014

3.3. Rapeseed Feedstocks for Biodiesel Production

Known scientifically as Brassica hapus L., rapeseed is also known as colza and one of the most cultivated crops globally only beaten in acreage by soybean [140]. Its main geographical origin is the Mediterranean area and northern Europe. Among the leading global producers of rapeseed include China, Germany Canada, India and France accounting for 65% of global production [140]. Table 9 shows Oil yield for major non-edible and edible oil sources and feedstocks.

In Europe rapeseed is the main plant biofuel source accounting for 55% of the total European production of biofuel feedstocks and 68% of global feedstock production in 2016. However, its market share has been slowly decreasing as more recycled oil and alternative feedstocks eat away its market share since 2016 [144]. Other usefulness of rapeseed is in the protein range and food supplements, rapeseed can be used as an animal feed for pigs, cattle, sheep and poultry [145, 146].

Table 9: Oil yield for major non-edible and edible oil sources

| Type of oil source (feedstock

|

(kg oil/ha)

|

Oil yield

(Wt %) |

Prices

(USD/ton)

|

Literature references |

| Jatropha | 1590 | Seed:35–40

kernel:50–60

|

370 | [5,6] |

| Rubber seed | 80–120 | 40–50 | 1250 | [7][147] |

| Castor | 1188 | 53 | 1600 | [5,9][148] |

| Pongamia pinnata | 225–2250 | 30–40 | 286 | [8],[149], [150] |

| Sea mango | N/A | 54 | N/A | [9] |

| Edible oil

Soybean |

375 | 20 | 684

|

[5,11] |

| Palm | 5000 | 20 | 600

|

[5,12 |

| Rapeseed | 1000 | 37–50 | 683 | [5,13 |

Rapeseed meal is known to contain 34% to 38% protein with an oil range of 34% to 40% [151]. However rapeseed has an unpleasant flavor due to glucosinolates which sometimes lead to toxicity in combination with the enicic acid [152]. This is one of the major drawbacks especially on cost reduction in related industries even though utilization can be undertaken by processing [153]. As a source of feedstock rapeseed has low levels of saturated fats coupled to high levels of monosaturated fats with omega 3 and 6 making it a healthy source for human consumption [96]. As a plant feedstock rapeseed ensures a steady acreage yield at stable production over a range of time [154] while allowing intercropping. Compared to soybean, and palm oil, rapeseed performs well in emission studies for example it reduces smoke, PM, and UHC [155]. Environmentally, life cycle studies report a wide range of mixed results. Nevertheless it reduces GHG emissions from 85% to 40% and fossil energy use from 83% to 43% compared to petroleum fuels [156].

3.4. Palm Oil Feed Stocks

Palm originate in West Africa and is used as the main feedstock for palm oil production. Palm oil plant has a life cycle of 26 years [157]. Palm plant as a feedstock generates co-products of 20% to 21% oil, 17% kernel oil, 3.5% palm kernel cake, 22% to 23% empty fruit bunches, 12% to 15% fiber, 5% to 7% shells and 50% liquid POME [158]. Palm oil plants are natural in Central America, north and south. Palm oil is rarely planted commercially due to its low oil content. As such attempts have been made to breed Elaeis OLEIFERA and Elaeis guineensis species to improve disease resistance, palm tree height and increase unsaturated fatty acid [159].

Palm oil as a biofuel feedstock is one of the leading vegetable oils with over 50 million metric tonnes accounting for 30% of global palm oil production in 2013 alone. However, by 2017 the production of palm oil rose to 37.6% (70.3 million metric tonnes) [124]. Nevertheless, as a feedstock only 10% of its global production goes to bioenergy and biofuels [160]. The leading producers of palm oil are Indonesia and Malaysia which control 85% of global production [130]. Palm oil in south east Asia was introduced in Malaysia in 1870 from Singapore [161]. As a feedstock, palm oil has a number of uses considering its byproducts. For example palm oil is used in the food industry as butter, solid fats, cooking oil, industrial oil, baking oil or as a substitute for trans-fat [159, 162].

Additionally, palm oil is applicable in the cleaning, cosmetic, and soap and detergent production. In the chemical industry palm oil is used as a lubricant and in oil production [162]. In waste to energy reform, palm oil shells and fiber can be used in chain production of steam for electricity in co-generation systems. For example, in literature surveyed it was reported that for a palm tree bunch the energy is 300 kWh and 600kg of steam [163, 164]. In literature-surveyed palm oil as a biofuel feedstock has limitations which include; (i) Low supply of seeds, hence poor production [165], (ii) Lack of research in co-product industries and comprehensive economic data due to logistical issues [166], (iii)The long cycle of the palm tree growth [130].

3.5. Cotton Seed Feedstocks

Cotton which is known scientifically as Gosypium hirsutum L., comes from the family of Malvaceae and is grown globally for the production of fiber used in the textile industry [167]. Cotton comprises of 65% seed and 35% fiber [168], oleic acid 15% to 20%, stearic acid 2% to 5% [167], with major fatty acid being palmitic acid at 27.76% while linoleic acid stands at 42.84% [169]. Nevertheless cotton as a feedstock for biofuels has a low oil content at 16% to 23% but with breeding and selection researchers have observed an improvement of 5% in crop oil yield [170].

However, what is of great interest is the cotton meal, which is heavily rich in protein second only to soybean after oil, has been extracted. The cotton meal is mainly used as an animal feed although it has other vital uses such as being a fertilizer, food flour or as a dye in the textile industry and as a biodiesel feedstock [171-174]. Globally cotton is the ninth highest oil producing plant [175]. Despite its low oil content cotton is advanced as a biofuel feedstock due to lower smoke and particulate emissions compared to other feedstocks such as palm oil discussed in earlier subsection [155]. Nevertheless it has limitation which include poor quality oil requiring pre-treatment hence increased cost of biodiesel production when used as a feedstock [114]. Figure 8 is showing a cottonseed oil sample after extraction from cotton seed.

Figure 8: A sample of cottonseed biodiesel layer of cottonseed oil [167]

Figure 8: A sample of cottonseed biodiesel layer of cottonseed oil [167]

3.6. Sunflower

Known as Helianthus annuus L and a dicotyledon, Its oil content varies from 38% to 50% based on the species of variety employed [176, 177]. Russia is the world leading producer of the sunflower crop with a 21% of the total global landmass, others include Ukraine at 12.97%, Argentina at 11.83%, China at 7.17%, Romania at 6.56%, France at 5.56% India at 4.77%, USA at 4.14% and Spain at 3.09% [178]. Globally sunflower covers an area of 23.7 million hectares with an annual production of 1322 kg/ha on an expected production of 2.3 tonnes to 2.5 tonnes/ha [179].

Beside its potential for oil, sunflower grain produces 250 kgs to 350 kgs of meal shell and 45% to 50% crude protein per tonne of grain [180]. The co-products of sunflower can be utilized for other uses such as in packaging materials, animal feeds, forage silage or as green manure or as a biofuel feedstock [181, 182]. Sunflower in the last decade has gained prominence as a feedstock, for example in Brazil 62000 tonnes were realized in the 2015 to 2016 season. However this was a decrease compared to the previous seasons due to a drop in the acreage under cultivation [183]. The introduction of new crops such as corn saw farmers shift to corn due to low cost of production of inputs and processing [184].

Sunflower is a good feedstock for biofuel due to its drought resistance to cold and heat conditions besides being less likely to be influenced by latitude, longitude or photoperiods [185]. As a feedstock sunflower can be grown in rotation with other plants (intercropping), which offers higher returns to farmers and producers [186]. The main limitations of sunflower as biofuel feedstock include High international market prices [134], besides a cloudy nature as temperatures drop due to its high wax content [187]. Additionally Sunflower contains linoleic, oleic and linoleic acids, which account for almost 70% hindering oxidative properties, which offer stability, hence rapid lipid oxidation of its oil [188-190].

3.7. Jatropa Curcas

This is a plant cultivated almost globally for the production of biofuel although it is a non-edible plant. Jatropa seeds are composed of 37 % shell, and 63% kernel (dry matter) with a protein content of 35% and a 15% of oil [191]. Jatropa has been on the radar of biofuel developers and producers due to a number of factors. These include low production cost, Water stress tolerance, High oil content and yield, Resistance to pests and diseases; Resistance to drought, Good adaptability to semi-arid wastelands, hence reduces competition with food crops for arable land [36, 192].

Other uses of Jatropa as a feedstock include as a cooking fuel, insecticide, soap making, and for medicinal purposes [191]). Additionally Jatropa can be used as an organic fertilizer, livestock feed and a biogas feedstock [193, 194]. On the other hand, the limitations of Jatropa arises: From uncertainties around its seed yield range which is 2 to 12 Mg/ha leading to poor economies of scale for a feedstock [36]. Secondly, even when it seems adaptable to drought during flowering studies have shown it needs watering otherwise the yield drops significantly.

In other words, Jatropa capabilities are not exploitable and applicable simultaneously. This is evidenced by the moisture and nutrients influence on yield [195]. The third limitation is due to its vulnerability to viral infection [36, 196, 197]. The fourth limitation is due to lack of scientific validation regarding the basic ecological and agronomical properties. For example, yield, potential production and costs, and breeding programs have not been identified in the literature reviewed.

4. Introduction to Non-Edible Vegetable Oil and Emerging Feedstocks

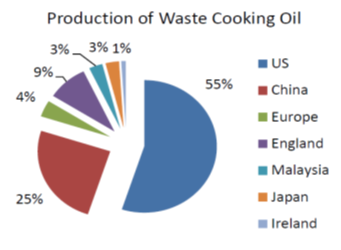

The use of non-edible feedstocks for biodiesel production is an answer to the challenges of edible oil as biofuel feedstocks. Non-edible feedstocks are gaining attention, as they are easily available globally in wastelands in unsuited for food crops. This eliminates competition for food, reduction in deforestation rate and co-products. Although there is no direct competition for food versus fuel, Nevertheless, there is indirect competition for land. Among the non-edible plants used for biofuel production include; Cotton (Gosypium hirsutum), Castor (Ricinus curcas), Jatropa (Jatropa curcas), Rubber (Hevea brasiciensis), Mahua (Madhuka indica), Ethiopian mustard (Brassica carinata), Castannola (Terminalia catappa) [198-202]. Figure 9 is showing Waste cooking oil production based on country and global contribution.

In India, there are two major species of the genus, Madhuka longifolia and Madhuka indica, on the other hand rubber seed tree is mainly in Indonesia, Malaysia, Liberia, India, Sri-lanka, Sarawak and Thailand. Rubber as feedstock contains seed kernels of 40 % to 50% brown oil [203]. Another non-edible oil biofuel source is neem (Azadirachta Indica) a natural plant of the Indian subcontinent and commercially grown in India, Bharma, and surrounding regions. Jojoba oil is another non-edible oil a shrub in southern Arizona. Therefore, in Literature reviewed non-edible oil studies as alternative biofuel feedstocks fill many researcher reports such as [44, 201, 204-207].

Figure 9: Waste cooking oil production based on country [10, 14-15]

Figure 9: Waste cooking oil production based on country [10, 14-15]

4.1. Waste Cooking Oil Feedstocks

Waste cooking oil is also known as yellow grease due to the fact that most waste cooking oil FFA content is 8% to 12% wt. Waste cooking oil offers a high potential as a feedstock to biofuel production due to low cost. As modernization grows and more people shift to urban lifestyles the total quantity of waste cooking oil has been growing since 2008. Waste cooking oil can be collected from households and hotels and restaurants, fast food outlets with heavy use of frying activities [208]. The disposal oil from these activities is problematic as it contaminates ground water. However, their cooking oil sources differ greatly since their base material are plant lipids like corn, margarine, coconut oil, palm oil, olive oil, soybean oil, grape seed oil and canola oil. The most commonly used material for vegetable oil is palm oil [209].

The use of WCO as a biofuel feedstock does not come at the expense food versus energy or land resources. Instead it’s a sustainable use of resources which reduces adverse effects of water pollution and blockage of water and drainage sewage system [210]. Presently WCO has been heavily utilized in soap manufacturing, although the soap produced is of poor quality hence its utilization has been low [211]. The main objective of using WCO is to transform it by reducing its viscosity to values close to diesel oil. Globally over 15 million tonnes of waste cooking oil are produced annually and if converted it can meet and satisfy the world demand of a biofuel feedstock [212]. Production of WCO oil as a biodiesel can contribute to a saving 21% in crude and a 96% energy saving [213].

Non-edible vegetable have potential to substitute a global fraction of petroleum diesel [214]. Plant oil feedstock when processed to biodiesel reduce particulate and sulfur emission and aromatic compounds [215] compared to petroleum diesel [216]. In 2009, the production of FAME waste oil was 11 tonnes with a demand increase of 3.5 metric tonnes/year. However, the production of waste oil in Europe, north America and in selected Asian countries such as China combined had a production of 16.6 metric tonnes [217, 218].

For example in 2014, China alone had a total WCO production of 1.8Mtonnes [112], pushing China to 3.4 Mtoe hence accounting for 2.9 % of global biofuel production, distributed in 50 plants. In other words, currently, the main leading feedstock of biofuel production in China is waste oil. However its main limitation is waste oil increased prices due to rapid development of the biofuel industry in the last decade [219].

The use of waste cooking oil has a number of challenges due to FFA and presence of high moisture, which make it hard for transesterification. Although chemical and physical properties of waste cooking oil are similar to fresh edible oil they differ from source to source [217]. For example, the water content and FFA in WCO compared to fresh edible is higher due to the frying process. During frying edible oil undergoes higher heating temperatures of 160 ℃ to 200℃ for a long and a sustained period.

As a result, increased viscosity specific, specific heat, surface tension, colour and fat formation occur. Hence reactions of thermolytic oxidative and hydrolytic nature are observed [220]. Nevertheless, current research centres in operation and management of waste to energy with the focus on the following two key areas. (i) The supply chain incentive, and (ii) regulation policies for WCO to energy.

There is a growing importance on the use of subsidies as a measure of addressing issues of waste to energy based on the model dynamics [221-229]. Regulation policies of waste cooking oil to energy report illegal transaction in waste cooking oil utilized as barriers to expanding WCO utilization. This need increases a requirement of standard inspection and regulations with dedicated infrastructure to help in recycling [223, 230, 231]. For example, in America in south California and north western Mexico [232].

4.2. Animal Fats Feedstocks

Tallow is the most common commercially available feedstock from animals for the production of biofuels [233]. The production of meat in the last decade increased significantly to 237.7 million tonnes in 2010 represented by 42.7%, 33.4% and 23.9% for pork, poultry and beef. Nevertheless, the projected growth of these resources increased steadily and now stand at 266909000 million tonnes annually [124]. This corresponds to a representation of 39.76%, 37.3% and 22.97% for pork, chicken and beef. However lard and chicken fat [234] are also commonly used in addition to insects and all other high fat containing animals.

The main reason for use of animal fats as feedstock source is due to their cheap and low prices, hence providing an economical option for biodiesel production [201, 233]. For example, since 2013 the prices of animals based fats has been $ 0.4 to $ 0.5/litre compared to vegetable oil at $0.6 to $0.8 [201]. In the world today 90% of feedstocks for biodiesel production originate from animal fats and greases compared to the USA at 8% to 10% [235]. In other words from this report there is an observed dynamic animal protein and being expressive especially in the poultry production which shows an annual growth of 4% to 5% in the last decade [236].

Animal fats are characterized by a high content of saturated fatty acids and as biological lipid materials they are composed of TAGs and less of di (DAGs), and mono-acylglycerols (MAGs). Animal fats and greases tend to be solid at room temperature compared to liquid oil of plant origin. This is due to their high content of SFAs [233]. Tallow is a waste final product generated in slaughterhouses and meat processing facilities, whose major composition is myristic, palmitic and stearic acids with tallow and pork lard composition of 40% SFA.

However in the literature surveyed the composition figure is higher for tallow at 45.6%, mutton tallow at 61.1%, lard at 39.3% and chicken fat at 32% [207]. Saturated fatty acids present increased demerits on the physical and chemical properties of biofuels. For example fatty acids cause poor cold properties while unsaturated animal fat content offers advantages of high cetane number, oxidation stability and high calorific value [234]. Thus considering the composition of animals fats as a source of biofuel requires synthesis at elevated temperatures compared to processing vegetable oil [237]. Animal fat greases are classified into two types as reported in literature. This classification is based on the level of FFAs,[207] such as Yellow greases with FFAs of ≤15% w/w and Brown greases with FFAs >15%w/w.

In theory animal fats are thought to contribute to oxidative stability for biodiesel, due to the lack of polysaturated fatty acids such as linoleic and linolenic commonly found in vegetable oil [238]. However comparatively in real-life, animal fats are unstable due to lack of anti-oxidants in their structure. Hence use of animal fats and greases eliminates the need for disposal and result in utilization to the supply of biofuels [239]. Like all feedstock, animal fats have limitations, for example, animal fats contain phospholipid or gums, which are insoluble in water.

These precipitates can plug fuel filters and render them ineffective. Secondly animal fats oil biodiesel deactivates exhaust pre-treatment devices in diesel vehicles [238]. Thirdly is the problem of the presence of high sulfur content mainly from sulfur containing amino acids traced from animal feeds [240]. Since animal fats are highly viscous and solid at ambient temperatures due to unsaturated fatty acids. This leads to poor atomization properties, hence incomplete combustion, while increases emissions of pollutants and particulate matter [241]

4.3. Algae Oil Feedstocks

The microalgae family contains more than 100000 species which can be utilized for biodiesel production [242]. However the most one with the highest probability of development in literature surveyed are green algae, diatoms and cyanobacteria (blue algae) [243]. Microalgae content is projected to hit 70% of dry matter and a yield of 90 tonnes/ha of cultivation [244].

Algae grow rapidly in different environmental conditions, while utilizing efficient use of water CO2 and nutrients on the water surface [245, 246]. This requires if planted in a pond stirring becomes a necessity to ensure accessibility to CO2 [247]. In addition to their faster growth and high yield content per acre, microalgae oil contains properties identical to petroleum fossil fuel. This is especially true for viscosity, density, flash point and the hydrogen carbon ratio [248].

Use of microalgae as an alternative fuel is being advanced as the fourth-generation biofuel as technology for producing and processing biofuels increases. This will enable its production as a biofuel to be cost effective for large-scale production in the near future. Microalgae compared to land-based plant feedstocks have efficient photosynthetic process in converting and utilizing solar energy into biomass [249]. The main algae, which can be utilized for the production of biofuel, are cyanobacteria as micro or macro algae.

Their sizes determine and influence the production process techniques. For example microalgae produce high oil content but their harvesting is costly due to low efficiency, cell size and low biomass concentration [250, 251]. On the other hand compared to cyanobacteria which are macroalgae the conversion rate into biomass is good but with a complex membrane rapture [252].

In the literature surveyed to produce algae it requires cell growing, separation, and lipid extraction [246]. The main microalgae growing technologies available vary but open pond and closed photobioreactors are commonly utilized [253]. In harvesting microalgae to extract oil physical chemical and enzymatic techniques are employed [254]. Processing of microalgae oil for biofuel production commonly takes the same route of processing and technologies used in vegetable oil and animal fats. It is important to note that fourth generation technologies for production of algal biofuels are still under research and development.

A number of questions remain unanswered. For example, in literature surveyed on algal feedstocks advantages and disadvantages of growing microalgae in fresh and salty water is not available in literature for all types of algae marked for biofuel production. Another factor noticed from literature surveyed is lack of feasibility studies whose data for biofuel microalgae is unavailable. For example, the cost of production for algae is projected at $0.9/kg to $2.55/kg in open pond systems compared to $1.5/kg to $5.5/kg using photobioreactors.

This is despite development in more realistic and appropriate technologies used for algae on commercial scale [243]. The methods utilized in the farming, harvesting and oil extraction for biofuel production still face surmountable difficulties. Nevertheless, microalgal diseases such as contamination are still not clear, although biofuel especially in chain and value addition offer high returns compared to other feedstocks [255]. If technologies are developed for value addition such as on pharmaceutical, nutraceuticals, biodiesel commercialization etc. could increase economic viability of algal feedstocks for production [256].

4.4. Waste Biomass Feedstocks

A number of waste resources arise in line with the diverse human economic and social activities. However, utilization of natural resources such as water, air, soil etc. are being threatened. This solid biomass wastes take many forms either as solids. Although classified as waste they can be reused and turned into energy resources for industrial and domestic purposes [257]. In the current world energy scenario, a number of waste to energy, technologies have emerged. These technologies convert waste biomass into various forms of fuel before utilization as biodiesel [258].

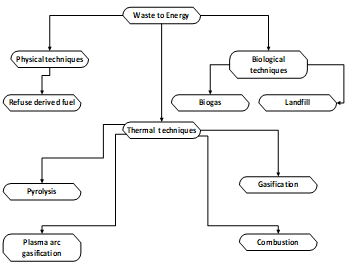

Bio-waste feedstocks differ greatly from primary sources such as coal, in both energy content and physical properties. However compared to coal bio-waste comprise low carbon, high oxygen content, high silica and potassium, less aluminium and iron, low heating values, high moisture, low density per unit of mass and friability [259]. Figure 10 shows the Main waste to energy (WTE) technologies available currently for the utilization of biomass waste.

Figure 10: Main waste to energy (WTE) technologies adapted from [259].

Figure 10: Main waste to energy (WTE) technologies adapted from [259].

However, utilization of natural resources such as water, air soil etc. is being threatened and takes many forms either as solids and can be utilized and reused to become energy resources for industrial and domestic use [260]. In the current world energy scenario, a number of wastes to energy technologies have emerged. These technologies convert waste biomass into various forms of fuel before utilization as a biofuel or biodiesel [259]. Depending on the use of the technology so is, the name derived.

For example in the literature surveyed technologies for fuel production are referred as waste to energy technologies (WFT) [259].The waste technologies include the following categories of utilization; Physical methods, Thermal methods and Biological methods. Globally these technologies have grown to nearly 750 facilities with a capacity to process 140 million tonnes of waste annually [261]. Energy from waste can be treated and compressed to solid fuel or converted into biogas, syngas, or combusted to produce heating for steam production in power generation. The gases produced in such cases include methane, CO2, hydrogen, and H3CO or liquid fuels such as ethanol and biodiesel [262].

Biomass to energy has potential feedstocks, which form its main potential line. These include wood, short rotation wood, crop waste, agricultural wastes, short rotation herbaceous crops and animal waste [263]. It is important to note that biomass accounts for 35 % of all energy consumption in developing countries [264, 265]. Nevertheless, biomass utilization carries a huge untapped potential for environmental and energy production, especially agricultural based plants absorbs CO2 during growth and emit it during combustion.

This helps in the recycling of CO2 in the atmosphere hence climate change mitigation [266]. Since biomass feedstocks contain lignocellulosic materials, they inherently produce high content of polymers such as cellulose (C6H10O5)x, hemicellulose (xylas) (C5H8O4)m, lignin (C9H1[267]0O3(OCH3)0.9-1.7]n and sometimes protein. This contributes to renewable energy sources, which are natural, sustainable, inexpensive and eco-friendly feedstocks [260]. Wood biomass thus forms the bulk of waste biomass accounting for 64%, municipal solid waste 24%, agricultural waste 5 % and landfill gases accounting for 5% [268, 269].

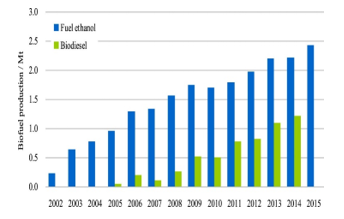

4.5. Bioethanol Feedstocks

Bioethanol is one of the leading clean and renewable energy sources in the transportation industry today. Globally bioethanol has seen a growth from 4.8 billion gallons in 2000 to 16 billion gallons in 2007 [270], representing a 30 % increase within the mentioned period. However, current statistic trends paint encouraging prospects, indicating for example that since 2007 with global production of 60 billion litres of bioethanol, by 2017 the figures stood at 143 billion litres annually [271].

Bioethanol has many advantages compared to fossil fuels such as high octane, which prevents knocking in internal combustion engines and high oxygen content, which helps to produce less greenhouse gas effects [272-274]. This advantages Allows direct use of ethanol in the automotive industry for internal combustion SI engines without modification and bioethanol works with other oils as a blending agent.

Currently the USA and Brazil are the leading global bioethanol producers with the two countries combined contributing 75 % to 80 % of the total global production [270, 273]. Using corn grain the USA has 187 bioethanol plants spread across different states to produce ethanol [275]. On the other hand, Brazil produces bioethanol from sugar cane based feedstocks only, compared to the European Union who use wheat and sugar beets. In 2013, Brazil produced 37 billion litres compared to European Union production of 5.785 billion litres of bioethanol and is expected to double its production in the near future.

Due to the reservation on plant-based feedstocks, in future renewable and sustainable feedstocks will dominate energy sources, hence replacing fossil fuels. Bioethanol has been a dominant feature of biofuels, nevertheless technology is moving to microalgae carbohydrates as potential feedstock [276-278]. Microalgae biomass feedstocks contain high contents of carbohydrates, (glycogen, starch, and cellulose) that through fermentation can be converted to sugars for production bioethanol [279, 280].

5. Factors Affecting Biodiesel Production

5.1. Biodiesel Quality

The quality of biodiesel of the feedstock used to produce a biodiesel determines the type of catalyst and process applied to produce FFA for the biodiesel production. Nevertheless, the biodiesel feedstock selection and determination are an important factor, inconsistence in the selection of feedstocks can lead to problems of quality and over-budget production. Suffice to mention that biodiesel fuels have standards recommended for their production such as ASTM D675 and EN14214. For example, feedstocks with more than FFA>3wt% cannot use homogeneous catalysts like NaOH, KOH or methoxide due to unwanted side reaction.

In order to produce biodiesel commercially the commonly used basic catalysts such as NaOH, KOH, or Methoxide are utilized. In addition, as a general rule acid catalyst are more appropriate for high FFA content feedstocks. On the other hand, homogeneous catalysts require less alcohol; have a shorter reaction time even though they result into complex products. This leads to required product purification compared to heterogeneous catalysed transesterification process. Development in catalysts has ensured use of a wide range of catalysts for biodiesel production such as heterogeneous and homogeneous acids, bases, sugars, lipases ion exchanges resins, zeolites etc. A number of researchers in the literature reviewed mention biodiesel quality as a factor influencing production include [135, 281-286].

5.2. Cost of Biodiesel Feedstocks, Investment and Material

Another factor that influences biodiesel fuel production is the higher cost of production arising from erratic feedstock prices as biodiesels gain widespread application. This is increased by the chemical composition due to their relatively low energy content increased NOx emissions compared to fossil fuels such petroleum diesel [287]. Price determination is an important factor of biodiesel production system and processing.

In every production system of biodiesel, a 50% feedstock price should be the guiding principle of all cost of production. Another factor to consider and is proposed in literature reviewed is price fluctuation especially when promoted through government policy shifts in relation to subsidies and tax incentives [8, 288, 289]. In other words when alternative sources are promoted there is diversification and stock piling to create demand and stabilize stabilization [287].

A number of researchers have reviewed and reported on this concept and can be read in some references provided here such as [239, 290-295]. In all the literature surveyed there is agreement that the higher cost of biofuel production is a major barrier for acceptability and use of biodiesel as an alternative fuel [296, 297].

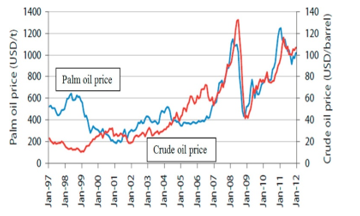

In literature surveyed, a number of suggestions thus come forward to address this issue. For example, use of cheaper alternatives catalysts Coupled to conversion technologies with lower energy input and faster transesterification reaction [201, 296, 298-301]. Another commonly suggested solution in literature surveyed is the diversification of feedstock by increasingly moving to material materials, not formerly considered as feedstock [302-304]. Figure 11 shows the effect of government policy and promotion to create demand and stabilize prices on palm compared to petroleum diesel.

Figure 11: Effect of government promotion on price of feedstock price fluctuation 1997-2012 [305]

Figure 11: Effect of government promotion on price of feedstock price fluctuation 1997-2012 [305]

5.3. Effect of Tax Policy Subsidy and Regulation

In order to empower biofuels and bring them into mainstream economy as usable fuels there is need to implement laws and regulation. These laws should include taxes, policies and subsidies from government as incentives to develop this sector. Particularly in the area of enforcement which mostly needs guidance in order to improve the basic economics of biodiesel.

In the literature surveyed for example, European Union has proposed a renewable energy policy for transport fuels to ensure a viable expansion of the biofuel industry in the near future. As a result, the European Union introduced a blending target in their range of biofuels, which involved hitting a target of 5.75% to 10 % by 2020. Additionally, an amendment to the fuel quality service brought into service a mandatory 6% reduction of GHG by 2020 for transport fuels and non-road and transport engines [306].

Between 2000-2013 biofuels such as ethanol and biodiesel grew exponentially in terms of output from 64 million to 23 billion litters and 0.8 to 14.7 billion litres respectively [307]. For example the USA also crafted a renewable fuel standard program to increase the share of biofuels by 10 % by 2017 and beyond since 2005 [308]. This increment in biofuel production is purely driven by government policy interventions. This is particularly so in the USA where financial incentives are almost guaranteed for producers [309].

Due to policy shift and incentives, a larger share of global biofuel market has been taken from ethanol to biodiesel in the market [310]. In other words, appropriate policies, tax, mandates and incentives can successfully drive growth of biodiesel. However, it is important to note that biodiesel incentives are distortionary in nature as biofuel use uniquely food crops and multiple feedstocks [311].

In other words, in 2006 for example 20 % of all USA corn production went to biofuels compared to ethanol. Although indicating a positive development in the growth of biofuel, this led to increased producer prices between 2003 to 2008 [312-315]. On the issue of regulation and GHG emission studies in literature reviewed, indicate a negative impact in reduction for specific types of crop feedstocks and their processing techniques. For example, this is revealed in studies conducted by researchers such as [316-318].

5.4. Competition with the Food Industry Chain

The increased biofuels production supported by the government policies interferes with food industry chain such as the oleo chemical industry. These industries use the same feedstocks as biofuels hence the rapid growth in the biofuel, which threatens their growth in the future. This is true considering the level of increased feedstock prices yearly. In other words, resource availability will be constrained hence causing a negative impact on the economic value of the food chain [288, 319, 320]. As the Competition for feedstock resources increases with greater incentives to encourage producers meet the demand. This leads to increased demand for resources and with it increased prices for land resources and prices for food [321].

In order to implement a sustainable biodiesel production strategy. The focus should not only be on reduction of GHG emissions but rather a complete package of policies, which support economic and environmental sustainability. However, one notes that the increased biofuel production from land resources and plant feedstocks is the leading cause of deforestation.

In recent trends governments defend their guidelines on implementation of sustainable policies on deforestation as is the case in brazil though it is not sustainable [288]. The second issue on sustainability is related to animal habitat destruction when deforestation is carried in large scale with some of these animals facing extinction [322]. This is due to replacement of virgin forests with plantations of plants such as palm oil. This can led to global warming especially in lower latitude areas while causing overcooling in high latitudes [323]. Use of biofuel in the transport industry when fully running is hoped to stabilize the global carbon cycle although deforestation will negate it. A practical example is in Malaysia where as a consequence GHG emissions increased to about 40 million tonnes of CO2 up from 5 years earlier at 20 million tonnes of CO2 [324, 325].

Another area that is often ignored in literature surveyed is change in land use, even with sustainable programs and policies. This problem is acute and severe in America, Mexico, and brazil where abuse of power forces farmers to sell land and move out leading to large population displacement and demographic changes [320]. However the European union seems to contain the problem by putting requirements for types of land to be used for biofuel production plantations as pointed in a number of literature surveyed such as [326, 327].

5.5. Biomass composition

In biomass composition, the most influencing factor is the carbon to hydrogen ratio. In other words, due to the differences in decomposition temperature for each of the constituents of biomass. These constituents thus undergo decomposition hence varying product yield. For example, in literature surveyed the following are the temperatures of the three main ligno-cellulosic biomasses [328-330]. This include Hemicellulose with a range of 150℃ to 350℃, Cellulose with a range of 275℃ to 350℃ and Lignin with a range of 250℃ to 500℃.

5.6. Particle Size

The particle size and composition, the physical structure and shape have a greater influence on the pyrolysis process products when exposed to heating [331]. For example, fine particles offer less resistance to escaping non-condensate gases and vice versa. This behaviour affects product yield [332]. In other words, size reduction of biomass before product extraction offers greater surface area for mass transfer. This enhances diffusion of the active components within the feedstock [333]. In literature surveyed, most scholars report these factors as variables in optimizing bio-oil production. Among the scholars who take this position, include the following researchers [334-337].

5.7. Effects of Temperature on Pyrolytic Process

Temperature is an essential factor of influence on pyrolytic product yield. Pyrolytic temperature defines the rate of increase from ambient to maximum until the completion of the process. Pyrolysis temperature thus influence composition and product yield and release rate of the constituent gases. Besides these components, the char produced depends on the pyrolysis temperature [336, 338, 339].

In other words, as the temperature of the reactor increases, the carbon content of the pyrolytic char products increases. This is due to the increase in surface area of the char. However beyond 1173k the temperature decreases slightly due to structural ordering and micropore coalescence with increasing temperature for char above 1073k [340, 341]. Increased heating rate results into a decrease in the carbon content while increasing hydrogen and oxygen content of the char [342].

In literature, surveyed pyrolysis takes many forms of processing but four forms of the criteria are critical namely: Slow pyrolysis, which is a carbonization pyrolytic process with a primary goal of producing charcoal and char. This is the oldest form of pyrolysis operating at below <400℃ over an extended period. Fast pyrolysis is tailored for liquid or bio-oils where biomass is subjected to rapid high temperature heating before decomposition begins. The rate of temperature increase can range from 1000℃/s to 10000℃/s. Nevertheless, the peak temperature is maintained between 650℃ to 1000℃. The main features of fast pyrolysis are high heating rate, reaction temperatures of 425℃ to 600℃, short residence time (<3s) and rapid cooling of the gas product.

Flash pyrolysis where rapid heating of biomass occurs in the absence of oxygen at moderate temperatures of 450℃ to 600℃. In other words, the products of both condensable and non-condensable gas leave the reactor unit faster (short residence time) of 30ms to 1500ms [331]. Ultra-rapid pyrolysis, which borders on the extreme fast mixing of biomass with heating and a carrier solid leading into high transfer of heat and rate of heating. Ultra-rapid pyrolysis utilizes temperatures of 1000℃ for gas components compared to 650℃ for liquids in order to minimize product yield [343, 344]

5.8. Effect of Heating Rate Change

It is important to note that the heating rate of biomass particles from rapid to moderate 400℃ to 600℃ leads to high volatile yields by producing more char [345]. Owing to fast volatile material release which causes internal pressure and coalescence of smaller pores leading to increased surface area [346]. A number of scholars have studied this phenomenon and reported on it widely such as [347-349]. Nevertheless in literature surveyed it is widely reported that high heating rates of 900℃, a lower surface area is produced and vice versa [350]. In other words higher heating rates cause high char yield interior temperatures, partial graphitization and curtails development of large surface areas [351].

5.9. Effects of Residence Time