Prioritization of Sustainable Supply Chain Management Practices in an Automotive Elastomer Manufacturer in Thailand

Volume 6, Issue 1, Page No 1079-1090, 2021

Author’s Name: Saruntorn Mongkolchaichana, Busaba Phruksaphanrata)

View Affiliations

Thammasat University Research Unit in Industrial Statistics and Operational Research, Industrial Engineering Department, Faculty of Engineering Thammasat University, Pathum-thani, 12121, Thailand

a)Author to whom correspondence should be addressed. E-mail: lbusaba@engr.tu.ac.th

Adv. Sci. Technol. Eng. Syst. J. 6(1), 1079-1090 (2021); ![]() DOI: 10.25046/aj0601120

DOI: 10.25046/aj0601120

Keywords: Sustainable supply chain management, Multiple attribute decision making, Logarithmic fuzzy preference programming, Prioritization, A case study

Export Citations

Nowadays the sustainable awareness trend is increasing. The consumers’ attitude has changed, causing companies to pay more attention to management in a sustainable way. Effective sustainable supply chain management (SSCM) can increase social, economic, and environmental benefits. Important factors from literatures were gather and organized to be a framework for SSCM. The proposed framework incorporates the whole supply chain for both internal and external activities, which can be applied to a manufacturer. The case study factory, which is an automotive elastomer producer has planned to adopt SSCM, so it needs to know the main factors for its operations. Logarithmic fuzzy preference programming method (LFPP) was used to rank SSCM criteria. The results of ranking important criteria showed that external factors (government and competition) were the most significant criteria that the factory has determined. Government and competitors are significant drivers that initiate the company to implement SSCM. Regulations and standards were good guidelines to SSCM for the factory. Next, the Triple Bottom Line (TBL) criteria (social, economic, environment) were considered in the overall operations. Not only concerning about cost and profit, but also environmental effect and social responsibility are cooperated. Finally, internal factors (supplier, consumption, and company) were considered with low level of importance. The proposals of actions of the company were also shown as a guideline for a manufacturer.

Received: 23 December 2020, Accepted: 03 February 2021, Published Online: 16 February 2021

1.Introduction

This paper is an extension of work of a similar concept presented initially in the ICIEA 2019 conference [1]. The previous work considered the criteria for green supply chain management (GSCM), while the current work extended the scope to sustainable supply chain management (SSCM). In this research, the main criteria for SSCM were collected and organized to be a new framework for an automotive elastomer factory [1–4].

The evolution of process flow management from raw materials to finished goods is known as supply chain management (SCM). SCM plays an important role in any organization’s success. However, there are many operations in the supply chain, which cause environmental impact to the social communities. The concept of sustainability has gained increased popularity due to the increase in environmental problems. Organization’s management strategies have to improve and adjust to the current world situation for survival and friendly environment by not destroying the environment and not harming social communities. The use of environmentally friendly raw materials in the most effective way is one of the interesting practices [5]. Moreover, the participation of communities by corporate social responsibility (CSR) activities or developing community projects, helps to ensure the longevity of the organization.

SSCM is effective management that considers economic, environmental, and social performances at the same time in the supply chain. The basic aim of GSCM is to eliminate all wastes within the industrial system and limit use of hazardous substances. The aims of SSCM concern not only profit but also environmental and social dimensions, called a Triple Bottom Line (TBL).Companies must consider environmental effects from processes in the supply chain such as purifying the toxic water or air emitted by the manufacturing process before releasing it to the environment to maintain good health in the community [6]. There are many pieces of research on case studies of SSCM. Some of them consider the specific operation in the supply chain such as supplier selection, reverse logistics, packing, etc [7–9]. However, the overall framework for SSCM for a supply chain needs to be clarified and important factors also need to be highlighted.

SSCM has various factors that affect the operations, which differ in each organization; also, the levels of action within each organization need to be considered differently too. Sari (2017) recommended considering inbound operations, production operations, outbound operations, and reverse logistics as primary criteria for the decision making in GSCM practices [10]. Uygun and Dede (2016) suggested a green design, green purchasing, green transformation, green logistics, and reverse logistics criteria. These activities are mainly concerned with environmental awareness [11]. Wu et al. (2020) and Mastrocinque et al. (2020) considered TBL as primary criteria throughout the SCM [12,13]. These criteria need to prioritize and formulate appropriate internal management strategies to achieve more benefit for the stakeholders in the most efficient way.

Multi-criteria decision making (MCDM) method is one of the most commonly used methods for ranking [14]. There are many methods of MCDM such as Analytical Hierarchy Process (AHP), Fuzzy Set Theory, Case-based Reasoning, Data Envelopment Analysis (DEA), Simple Multi-Attribute Rating Technique, Goal Programming, Simple Additive Weighting (SAW), and Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) [15,16]. However, in evaluation criteria, the decision-maker may not be able to precisely decide the value for the decision, so the fuzzy set concept was proposed [17]. Then, many fuzzy methods for prioritization were presented [18]; these include the logarithmic least-squares method, geometric mean method, extent analysis method, lambda-max method, fuzzy preference programming method (FPP), linear goal programming method, and logarithmic fuzzy preference programming method (LFPP). Nevertheless, these methods still have some pitfalls to avoid [19–21]. The LFPP method has been chosen in this research to prioritize the criteria for three main reasons. The first reason is realistic computation; there is not an argument about this method from literature reviews. The second reason is that the data’s consistency can be calculated, and can be re-evaluated over a short evaluation time. Finally, LFPP can maintain Saaty’s AHP assessment rules in all aspects.

In this research, a case study of an automotive elastomer manufacturer was studied. Currently, the case study factory has already applied GSCM, but the management team desire to get a higher level of consideration about sustainability to survive in rapidly changing societies. The new goal of the factory is to implement SSCM in order to focus on social, economic, and environmental aspects. So, the main criteria that influence SSCM implementation should be investigated initially. A new framework of SSCM for the factory is presented. The organization’s main objective is to achieve the lowest internal costs (the most profitable) and the least impact on the environment (using environmentally friendly raw materials and the most efficient use) to ensure that the product is green before releasing it to the market and consumers. Criteria were used to construct a new framework composed of SSCM factors for both internal and external factors, it can be used with any factory. All critical factors are integrated into the framework, which can satisfy the qualified policy of the factory. This research aims to prioritize the important criteria that affect the SSCM of the case study factory by use of LFPP, so that the factory can know which criteria should be emphasized and invested firstly. Then, the goals and direction can be clearly set. The proposals of actions of the factory also present in this research.

This research is organized as follows: Section 2 mentions the definition of SSCM and the detail about SSCM activities involved in the operations. Relevant literature was reviewed to determine the important criteria for SSCM of the case study. Section 3, calculation procedure by LFPP method is discussed. Section 4, the results from prioritization of the important criteria that affect the SSCM in this case study are deliberated. Conclusion, discussion, and future research are presented in section 5.

2. Sustainable Supply Chain Management

SSCM is an extension of GSCM, which mainly focuses on environmental, economic, and social dimensions [7]. These three dimensions are related to the Triple Bottom Line (TBL) principles [22], in which the perspectives are focused on the achievement and success of an organization in the economy, environment, and society as shown in Figure 1. They are the key to success of sustainable development, which needs to be balanced [13,22,23].

Figure 1: Triple bottom line for SSCM [24]

Figure 1: Triple bottom line for SSCM [24]

The objective of the organization previously only focused on profit, which cannot maintain sustainability. Many companies have turned to concern about people, societies, stakeholders, planet, and environmental responsibility. The TBL-based business aim is not only high profit, but also more consideration about the social and environmental problems. TBL shows profit at the top of the triangle. It is an economic dimension that almost all organizations desire.

The concept of people or humans in TBL is to emphasize fair business practices to the communities, employees, and societies by not causing harm to workers and people in the communities, but at the same time, the business has to make a profit for shareholders. Moreover, fair trade must be performed for the people dimension to balance with a social perspective.

Planet or natural dimension means a business should support sustainability and the diversity of the environment. The operations of the company must produce as little waste as possible from resources and must use recycling methods and reduce toxic gas and wastes to secure the environment and biodiversity, so the planet dimension is identical with an environmental perspective.

2.1. Sustainable activities

SSCM has comprehensive activities throughout the workflow processes. SSCM activities must care about social, economic, and environmental dimensions at the same time. These three perspectives incorporated with administrative activities start from planning strategies through to reverse logistics activities. They are described as follows:

- Sustainable strategy and planning: Strategic planning by top management is essential for organizations’ initiative to improve and change [25]. If there is no strategic planning or goal setting, there is no direction that makes people understand the management intent [29, 30]. The implementation of SSCM defines the company’s goal to sustainability, in which everyone should adhere to the three perspectives: social, economic, and the environment in all operations.

- Sustainable design: The design is not only for recyclable packaging or readily biodegradable products [8,28,29]; SSCM’s sustainability design goes beyond that. Green design is a comprehensive design across SCM that is the best starting point for green purchasing, green production, green packaging, and green logistics. In recent years, biodegradable materials from renewable natural resources have received extensive government support.

- Sustainable purchasing: The purchasing managers need to be aware of sustainable raw materials that have to be compared among suppliers. There are many factors to be concerned about, which are cost, delivery, quality, environmentally friendly products, and value. Besides, the company also has the freedom to choose suppliers and avoid bribery from suppliers [7].

- Sustainable production: The production process design has many points to consider [8], such as a suitable location for machinery to reduce energy consumption or less fuel consumption and to get the best performance, type of source of energy, the amount of waste produced by the production [30].

- Sustainable packaging: The essential feature of product packaging is the ability to protect products from contamination damage, and deterioration. The packaging design may include special techniques to make good quality packaging, which is designed according to the 3R theory, which is recyclable (the product can be modified and reuse), reduce (reduce the use of raw materials in the production of packaging or the product itself), and reuse (the product or packaging can be reused). Also, packaging design should be easily disassembled for digestibility and create as low waste material percentage as possible [8,28,30]. Moreover, biodegradable packaging is also a favorite choice for manufacturers.

- Sustainable logistics: The green logistics design process has many points to consider, such as the design of the distribution route for the most efficient transportation, the minimization of the number of trips [31,32], the reduction of transport cost, the volume of the empty return transport called backhauling [33], the selection of transport vehicles to reduce CO2 emissions that cause environmental impact [34], the selection of third-party logistics service providers [35], the warehouse design for convenient loading and unloading of products without congestion, and the reduction of waiting time and administrative costs [28]. If sustainable logistics can be applied, it can cover three perspectives, which are social perspectives such as management of traffic congestion, economic perspective by reducing the transportation cost and transportation fuel consumption, and environment perspective by reducing the number of transportation trips and distances to reduce the greenhouse gas emission.

- Sustainable consumption: Determine how to consume the raw materials in the right way to minimize the processes that bring environmental pollution. The instructions must be written in words that are easily understood. The company must analyze consumer trends, consumer characteristics [36], customer green preference [37,38], and consumer purchase behavior [39] of the new generation of people who are becoming increasingly influential in the global green and sustainable market [40].

- Sustainable reverse logistics: Due to the increasing environmental impact today, various industries need more control over the amount of waste from the production processes [9]. Controlling waste is a waste management process that needs to delve into great detail to achieve the most efficient reduction in pollution and use resources efficiently [28]. Therefore, setting up a waste center is needed to receive the used products to facilitate consumers and initiate reverse logistics to be more successful [40].

2.2. Sustainable criteria for implementation

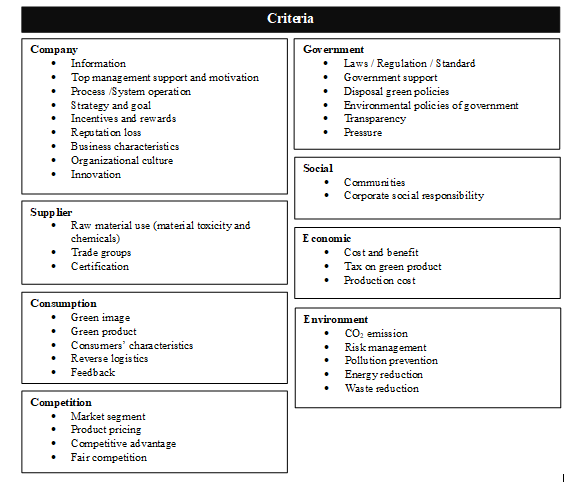

Every activity consists of essential components; for example, green purchasing has a vital role in choosing which supplier is suitable to deliver material that satisfies the company’s qualification standards. Therefore, a review of the critical criteria that directly affect SSCM activities must be compiled to cover all management practices. In the previous work, the guidelines for GSCM were proposed [1]. There are 6 criteria: government, competitor, social, supplier, customer, and company to prioritize the criteria that are important to GSCM. Further pieces of literature have proposed more criteria for SSCM. These criteria can be incorporated to construct the SSCM framework for defining an action plan as shown in Table 1.

Table 1: The main criteria for SSCM implementation.

| Criteria | company | supplier | competition | consumption | government | social | economic | environment |

| [2] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| [3] | ✓ | – | – | – | – | ✓ | ✓ | ✓ |

| [4] | ✓ | ✓ | ✓ | – | – | ✓ | ✓ | ✓ |

| [5] | ✓ | – | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| [8] | ✓ | – | – | – | ✓ | ✓ | ✓ | ✓ |

| [13] | ✓ | – | – | – | ✓ | ✓ | ✓ | ✓ |

| [26] | ✓ | – | ✓ | – | – | – | – | ✓ |

| [27] | ✓ | ✓ | – | ✓ | ✓ | – | ✓ | – |

| [29] | ✓ | ✓ | – | – | – | – | ✓ | ✓ |

| [41] | ✓ | ✓ | – | ✓ | – | – | – | – |

| [42] | ✓ | – | – | – | – | ✓ | ✓ | ✓ |

| [43] | ✓ | – | ✓ | ✓ | – | – | ✓ | – |

| [44] | ✓ | ✓ | – | ✓ | – | – | – | ✓ |

| [45] | ✓ | ✓ | – | ✓ | ✓ | – | – | ✓ |

| [46] | ✓ | – | – | – | – | – | – | ✓ |

| [47] | ✓ | – | – | – | ✓ | ✓ | ✓ | ✓ |

| [48] | ✓ | ✓ | ✓ | ✓ | – | – | – | ✓ |

| [49] | ✓ | – | – | – | – | ✓ | – | ✓ |

| [50] | ✓ | ✓ | – | – | – | ✓ | ✓ | ✓ |

| [51] | ✓ | ✓ | ✓ | – | ✓ | ✓ | ✓ | ✓ |

| [52] | ✓ | ✓ | – | – | – | – | ✓ | – |

| [53] | ✓ | ✓ | – | – | – | – | ✓ | ✓ |

| [54] | ✓ | – | – | ✓ | ✓ | – | ✓ | – |

There are 8 main criteria related to SSCM; company, supplier, competition, consumption, government, social, economic, and environment.

2.3. The sustainable supply chain management framework

In the past, the SCM of an organization was not complicated and consisted of a few stakeholders. Most companies focused on developing economic efficiency, such as technical quality development, reducing cost, and improving delivery performance. However, today, business operations are more complicated, leading to a broader range of stakeholders [55]. Supply chain activities are transformed into a complicated network model [56]. The suppliers, manufacturers, distributors, and logistic providers must work together to enhance their competitiveness. Meanwhile, other stakeholders such as consumers, investors, employees, and society pressure the manufacturers to be concerned about social and environmental issues that affect them. Therefore, nowadays organizations have adopted a sustainable development approach to their SCM [6,33], which considers whole parts of the operation throughout the supply chain known as SSCM. SSCM helps the organization to reduce the risk rate and enhances the competitiveness of the business. Promoting good corporate governance throughout the life cycle of products and services can improve environmental performance, social performance, operations performance, and competitiveness of an organization [57].

Figure 2: A framework of an SSCM for a manufacturer

Figure 2: A framework of an SSCM for a manufacturer

A new framework of an SSCM is proposed in this research as shown in Figure 2. It consists of three parts. The first part is external factors, referring to surrounding factors that can indirectly affect the corporate supply chain, which are competition and government. The second part is internal factors, referring to the composition of the main parts of the supply chain, which start from supplier, to company, and end at consumption. Next, the TBL consists of environmental, social, and economic aspects. They are the basis for sustainability. Sustainability tools can be applied to the framework to support the implementation. Whitehead et al. (2020) proposed the tools, which consist of 3 groups; tools for action, tools for analysis and evaluation, and tools for communication [58]. It is also summarized tools and approaches for sustainability, which are cradle to cradle, GSCM, life cycle analysis (LCA), eco-design, reverse logistics, design for environment (DFE), Quality Function Deployment (QFD) for the environment, sustainable value analysis tool (SVAT), sustainability balanced scorecard (SBSC), corporate social responsibility (RSC) and sustainable value stream mapping (Sus-VSM) [59]. These sustainability tools can help an organization’s supply chain to achieve successful SSCM. Criteria based on the framework are summarized in Figure 3. They can be described as follows.

Government is the criterion related to enacting laws to enforce and setting standards or regulations that industrial factories must follow. Government criterion is divided into two parts: enforcement of laws or policies and recommendations for manufacturers from the government. Industries must follow the government laws; if any factory fails to follow the laws, there are penalties. Policies and recommendations from the government might be disregarded if the company is not willing to implement them. It depends on the individual organization’s willingness or the opinions of executives within the organization. Many policies require action and enforcement that a business may select by itself or by the government. The role whereby a government can facilitate sustainability will depend on its authority which is different in each country. For example, a government with strong political leaders may generate models which benefit the local community and focus on supporting economic growth. In welfare-state models, the government provides services to firms and nonprofit organizations or takes on social-economic development [60]. Manufacturers determine their profit and level of energy efficiency. The government has sustainable goals that relate to saving energy, seeking profit, and increasing social welfare. Therefore, sustainability is a fundamental issue for both organizations and the government [61].

Competition in the market is one of the critical factors. Competition may be in the form of price, quality, variety of products, responsiveness, or environmental awareness, etc. In the case of SSCM implementation, social trends and substitute goods can affect consumers in making a decision. The organization should be concerned about the market trend to adapt to the competitive market. If the organization does not become active or is slow to adjust to consumption flow, it will lose market share. Competition in each type of market is different. Every organization needs fair competition as an ideal, but in the real situation, it may not be. Therefore, the rapid change of the organization is an advantage and benefit for the organization. The company’s choices can affect the decisions of the firm’s competitors. The firm invests in sustainability only if it can gain more revenue or reduce cost [62].

Economic sustainability has been defined as gaining more income and stability for society. In the current situation, an economy which does not disturb natural, social, and human societies is needed for sustainability [63]. If the current situation of the economy is getting worse, the investment in SSCM operations will be debated at management board level, and the SSCM operations may be delayed. On the other hand, if the economy is good, a high profit from operations or good cash flow may allow an organization to be able to start SSCM operation quickly. Moreover, the policy formulation from the government is an important factor. For example, if the government requires less tax on the green product, the product price will not be high, it will generate more incentives for consumption and produce more profit. The organization also wants to make more of the products that are best-sellers in the market. All the above result from the first criterion, which is government.

The social factor has direct and indirect effects on SSCM that start with employees on the production line. If the organization has sustainable production management, such as equipped with technology to optimize the use of resources as needed and get the most efficient outputs, minimize energy consumption and air polluting emissions [64], employees do not have the risk of direct exposure to volatile chemicals during production, production accidents will be reduced and the operators of manufacturing plant should have a good quality of life as well. Furthermore, supposing the organization has a policy to apply CSR, it will benefit the surrounding communities. The government is very important in supporting the policy by reducing tax for industrial factories that implement CSR [65, 66], which makes companies willing to undertake CSR projects.

The environment is related to various problems concerning pollutants from water [67], air, and other wastes from factories, which create increasing problems. Reduction of CO2 emissions, energy consumption [71, 72] and wastes from the processes, products, packaging, and any substances that can increase the world’s temperature, are critical issues. Different environmental regulations have started to emerge and be proposed to companies by governments. Companies must comply with environmental legislation existing in each country. Moreover, standards related to environmental consideration are one of the effective tools for the company to apply.

Selecting suppliers that market environmentally friendly raw materials without affecting the surrounding communities can help when implementing SSCM. However, this criterion is difficult to apply in order to make a significant impact on SSCM because organizations cannot enforce or control all suppliers, so choosing a supplier is yet another option in implementing SSCM within the organization. The selection of suppliers requires several factors to be considered [22, 70]. The key principles are the high quality of raw materials, reasonable prices, and on-time delivery.

Consumption can take place only if consumers are more aware of the environment and communities. The eco-label campaign is part of the approachability that can greatly appeal to consumers who are passionate about green consumption. Using its features is an important selling point. Currently, the consumer has a greater preference for healthy and environmentally friendly products [71]. Consumer perspective in sustainability is the driver for a company in the caring economy [72].

The company, including the management team, realize that the operation of SSCM requires a budget for investment [62]. Furthermore, employees within the organization have to adjust to the work with more responsibilities [73]. They must also cooperate to achieve the company strategic goal of SSCM. Moreover, organizations should provide support such as services, knowledge, information, training and facilities for them to achieve efficiency and effectiveness as soon as possible.

Figure 3: The descriptions of SSCM criteria

Figure 3: The descriptions of SSCM criteria

3. Logarithmic fuzzy preference programming method

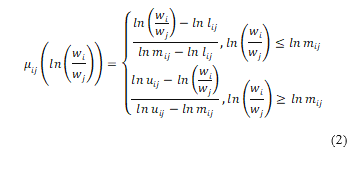

Wang and Chin (2011) have proposed a logarithmic fuzzy preference programming method (LFPP) for finding the weight to prioritize the fuzzy number by comparing pairs of the dataset from the decision matrix [74]. The basis of this method was developed from the FPP method of Mikhailov (2004) by using nonlinear functions computation to find the weight with the following [75]:

![]() where ãij is an approximate triangular fuzzy number.

where ãij is an approximate triangular fuzzy number.

The membership function is shown below.

µij (ln (wi/wj)) is a membership of function ln (wi/wj) belonging to the approximate triangular fuzzy judgment ln ãij. A crisp priority vector to maximize the minimum membership degree l = min{µij(ln(wi/wj)) | i = 1,…, n – 1; j = i + 1,.., n}. The subsequent model can be constructed as

µij (ln (wi/wj)) is a membership of function ln (wi/wj) belonging to the approximate triangular fuzzy judgment ln ãij. A crisp priority vector to maximize the minimum membership degree l = min{µij(ln(wi/wj)) | i = 1,…, n – 1; j = i + 1,.., n}. The subsequent model can be constructed as

Maximize l

Maximize 1 – l

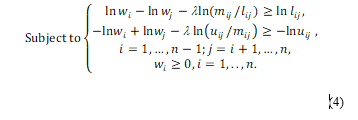

To avoid l from taking a negative value, Wang and Chin (2011) proposed nonnegative deviation variables dij and hij for i = 1,…,n-1 and j = i + 1,…, n such that they meet the following inequalities:

To avoid l from taking a negative value, Wang and Chin (2011) proposed nonnegative deviation variables dij and hij for i = 1,…,n-1 and j = i + 1,…, n such that they meet the following inequalities:

ln wi – ln wj – lln(mij/lij) + dij ≥ ln lij, i = 1,…, n – 1; j = i + 1,…, n,

– ln wi + ln wj – lln(uij/mij) + hij ≥ – ln uij, i = 1,…, n – 1; j = i + 1,…, n.

Then, the model to maximize the minimum membership degree becomes

MODEL: LFPP

M is a large constant value, xi* is an optimal solution, l is a membership degree, dij, hij are nonnegative deviation variables for i = 1,…, n–1 and j = i + 1,…, n and

M is a large constant value, xi* is an optimal solution, l is a membership degree, dij, hij are nonnegative deviation variables for i = 1,…, n–1 and j = i + 1,…, n and

lij = 1/uji, mij = 1/mji, uij = 1/lji and 0 < lij ≤ mij ≤ uij for all i,j = 1,. . . ,n; j – i.

Normalize the value of and sorting fuzzy pairwise comparison matrices by (6)

where exp( ) is the function of exponential for which the calculation is exp(xi*) = e xi* for i = 1,…, n.

wi* is the weight of each criterion from i = 1,…, n.

The following equation is used to check the consistency of data.

lij ≤ wi/wj ≤ uij, i = 1,…, n-1, j = i + 1,…, n. (7)

4. Prioritizing of SSCM criteria for the case study

The SCM process of an automotive elastomer manufacturer has a flow chart as shown in Figure 2. The supply chain flow process begins with the purchasing process, where sources of the best raw materials for the company such as a polymer, fillers, softeners, and other additives are procured. A supplier who has the lowest cost, which high-quality products and delivery on time was selected. After receiving raw materials, the production is done according to production planning. After the products are finished and pass the quality inspection, they are transferred to the packing process. Then, finished goods are delivered to customers. There are environmental concerns in all of the above activities, which need to be reviewed through three aspects: social, economic, and environmental. These processes are internal factors of the SCM. Additionally, the process would not be complete if it did not take the external factors into account. The external factors are competitors and the government. The competition between the companies is considered in terms of price, quality, strategies, and market share. Also, the company needs to follow the laws and regulations of the government. However, the government also provides support to the company to reach international standards. The three sustainable perspectives are integrated with both internal and external factors. The company can control all processes by setting the procedures for each aspect by using sustainability tools that can help an organization’s supply chain to achieve successful SSCM.

The automotive elastomer manufacturer has decided to apply SSCM in the company, so the importance of each criterion needs to be clarified. Then, everyone in the company can move in the same direction emphasizing the critical criteria. Eight criteria in the previous section were considered and ranked. A fuzzy decision matrix was constructed and evaluated by five experts who are key men in the factory: the procurement supervisor, planning supervisor, quality control supervisor, production engineer, and research and development engineer who has worked in this company for more than 10 years. The decision matrix is shown in Table 2. Model in equation (5) for this fuzzy pairwise comparison matrix can be written as

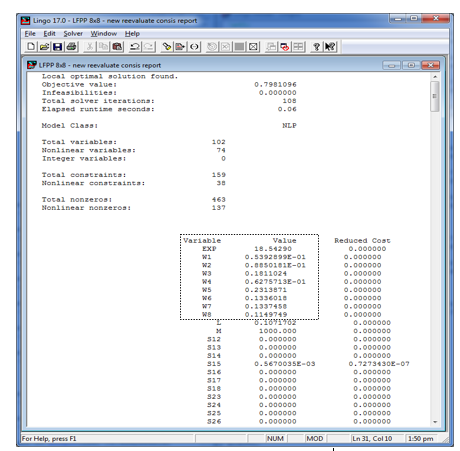

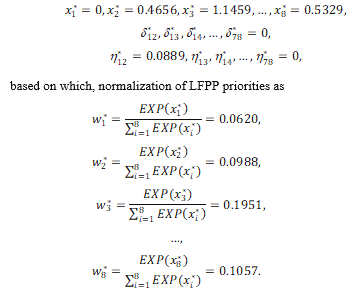

Taking a sufficiently large number for M, say M=1000, to solve this model with Lingo 17.0 as shown in Figure 4, the optimal solution can be obtained as

Taking a sufficiently large number for M, say M=1000, to solve this model with Lingo 17.0 as shown in Figure 4, the optimal solution can be obtained as

Table 2: Fuzzy comparison matrix of the aggregated weights of the criteria

| Criteria | C1 | C2 | C3 | C4 | |||||||||

| Company | Supplier | Competition | Consumption | ||||||||||

| C1 | Company | 1.00 | 1.00 | 1.00 | 0.26 | 0.35 | 0.57 | 0.24 | 0.34 | 0.46 | 0.80 | 1.52 | 2.41 |

| C2 | Supplier | 1.74 | 2.83 | 3.87 | 1.00 | 1.00 | 1.00 | 0.29 | 0.37 | 0.51 | 1.25 | 2.00 | 3.06 |

| C3 | Competition | 2.19 | 2.93 | 4.11 | 1.97 | 2.69 | 3.47 | 1.00 | 1.00 | 1.00 | 1.32 | 2.05 | 3.10 |

| C4 | Consumption | 0.42 | 0.66 | 1.25 | 0.33 | 0.50 | 0.80 | 0.32 | 0.49 | 0.76 | 1.00 | 1.00 | 1.00 |

| C5 | Government | 1.55 | 2.64 | 3.68 | 2.76 | 3.82 | 4.85 | 0.49 | 0.80 | 1.35 | 2.30 | 3.32 | 4.34 |

| C6 | Social | 1.64 | 2.09 | 3.13 | 1.07 | 1.52 | 2.22 | 0.40 | 0.64 | 0.94 | 1.00 | 1.52 | 2.46 |

| C7 | Economic | 1.43 | 2.00 | 5.00 | 1.05 | 1.28 | 2.78 | 0.45 | 0.81 | 1.00 | 1.01 | 1.56 | 2.56 |

| C8 | Environment | 1.59 | 2.94 | 3.33 | 1.27 | 1.61 | 2.50 | 0.45 | 0.66 | 0.99 | 1.28 | 1.79 | 4.35 |

| Criteria | C5 | C6 | C7 | C8 | |||||||||

| Government | Social | Economic | Environment | ||||||||||

| C1 | Company | 0.27 | 0.38 | 0.64 | 0.32 | 0.48 | 0.61 | 0.20 | 0.50 | 0.70 | 0.30 | 0.34 | 0.63 |

| C2 | Supplier | 0.21 | 0.26 | 0.36 | 0.45 | 0.66 | 0.93 | 0.36 | 0.78 | 0.95 | 0.40 | 0.62 | 0.79 |

| C3 | Competition | 0.74 | 1.25 | 2.05 | 1.06 | 1.55 | 2.49 | 1.00 | 1.23 | 2.21 | 1.01 | 1.51 | 2.22 |

| C4 | Consumption | 0.23 | 0.30 | 0.44 | 0.41 | 0.66 | 1.00 | 0.39 | 0.64 | 0.99 | 0.23 | 0.56 | 0.78 |

| C5 | Government | 1.00 | 1.00 | 1.00 | 1.52 | 2.27 | 3.37 | 1.49 | 2.07 | 3.07 | 1.09 | 1.98 | 2.98 |

| C6 | Social | 0.30 | 0.44 | 0.66 | 1.00 | 1.00 | 1.00 | 0.98 | 0.99 | 1.00 | 1.01 | 1.12 | 1.32 |

| C7 | Economic | 0.33 | 0.48 | 0.67 | 1.00 | 1.01 | 1.02 | 1.00 | 1.00 | 1.00 | 0.99 | 2.09 | 3.19 |

| C8 | Environment | 0.34 | 0.51 | 0.92 | 0.76 | 0.89 | 0.99 | 0.31 | 0.48 | 1.01 | 1.00 | 1.00 | 1.00 |

Figure 4: The result obtained from Lingo 17.0.

Figure 4: The result obtained from Lingo 17.0.

According to (7), the results of the consistent test found that there were four pairs outside the specified limits: a12, a15, a23, and a25, so the decision-makers needed to reevaluate the pairwise comparison judgment as shown in Table 3.

According to (7), the results of the consistent test found that there were four pairs outside the specified limits: a12, a15, a23, and a25, so the decision-makers needed to reevaluate the pairwise comparison judgment as shown in Table 3.

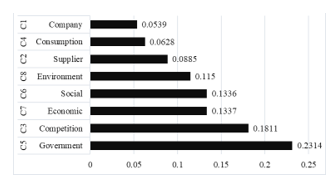

After reevaluating, weights were found and the importance could be sorted as shown in Table 4 and Figure 5. Lingo 17.0 with Intel (R) Core (TM) i5-3570 CPU @ 3.40GHz RAM 8.00 GB 64-bit was used to calculate weights of each criteria. The total calculation time for weights criteria was 0.06 seconds.

The prioritizing results clearly show that external factors, which are government and competition, are the main criteria for applying SSCM in the factory. Then, the economic, social, and environment criteria, which are TBL factors for sustainability, are considered. Their weights are similar which means that the emphasis of the factory on TBL is balanced. Finally, supplier, consumption, and company, which are internal factors have lower weightings.

Table 3: Reevaluate fuzzy comparison matrix

| Criteria | C1 | C2 | C3 | C4 | |||||||||||

| Company | Supplier | Competition | Consumption | ||||||||||||

| C1 | Company | 1.00 | 1.00 | 1.00 | 0.26 | 0.35 | 0.65 | 0.24 | 0.34 | 0.46 | 0.80 | 1.52 | 2.41 | ||

| C2 | Supplier | 1.54 | 2.83 | 3.87 | 1.00 | 1.00 | 1.00 | 0.29 | 0.37 | 0.52 | 1.25 | 2.00 | 3.06 | ||

| C3 | Competition | 2.19 | 2.93 | 4.11 | 1.92 | 2.69 | 3.47 | 1.00 | 1.00 | 1.00 | 1.32 | 2.05 | 3.10 | ||

| C4 | Consumption | 0.42 | 0.66 | 1.25 | 0.33 | 0.50 | 0.80 | 0.32 | 0.49 | 0.76 | 1.00 | 1.00 | 1.00 | ||

| C5 | Government | 1.55 | 2.64 | 4.55 | 2.50 | 3.82 | 4.85 | 0.49 | 0.80 | 1.35 | 2.30 | 3.32 | 4.34 | ||

| C6 | Social | 1.64 | 2.09 | 3.13 | 1.07 | 1.52 | 2.22 | 0.40 | 0.64 | 0.94 | 1.00 | 1.52 | 2.46 | ||

| C7 | Economic | 1.43 | 2.00 | 5.00 | 1.05 | 1.28 | 2.78 | 0.45 | 0.81 | 1.00 | 1.01 | 1.56 | 2.56 | ||

| C8 | Environment | 1.59 | 2.94 | 3.33 | 1.27 | 1.61 | 2.50 | 0.45 | 0.66 | 0.99 | 1.28 | 1.79 | 4.35 | ||

| Criteria | C5 | C6 | C7 | C8 | |||||||||||

| Government | Social | Economic | Environment | ||||||||||||

| C1 | Company | 0.22 | 0.38 | 0.64 | 0.32 | 0.48 | 0.61 | 0.20 | 0.50 | 0.70 | 0.30 | 0.34 | 0.63 | ||

| C2 | Supplier | 0.21 | 0.26 | 0.40 | 0.45 | 0.66 | 0.93 | 0.36 | 0.78 | 0.95 | 0.40 | 0.62 | 0.79 | ||

| C3 | Competition | 0.74 | 1.25 | 2.05 | 1.06 | 1.55 | 2.49 | 1.00 | 1.23 | 2.21 | 1.01 | 1.51 | 2.22 | ||

| C4 | Consumption | 0.23 | 0.30 | 0.44 | 0.41 | 0.66 | 1.00 | 0.39 | 0.64 | 0.99 | 0.23 | 0.56 | 0.78 | ||

| C5 | Government | 1.00 | 1.00 | 1.00 | 1.52 | 2.27 | 3.37 | 1.49 | 2.07 | 3.07 | 1.09 | 1.98 | 2.98 | ||

| C6 | Social | 0.30 | 0.44 | 0.66 | 1.00 | 1.00 | 1.00 | 0.98 | 0.99 | 1.00 | 1.01 | 1.12 | 1.32 | ||

| C7 | Economic | 0.33 | 0.48 | 0.67 | 1.00 | 1.01 | 1.02 | 1.00 | 1.00 | 1.00 | 0.99 | 2.09 | 3.19 | ||

| C8 | Environment | 0.34 | 0.51 | 0.92 | 0.76 | 0.89 | 0.99 | 0.31 | 0.48 | 1.01 | 1.00 | 1.00 | 1.00 | ||

Table 4: Comparison result for reevaluate

| Criteria | Weight | |

| C5 | Government | 0.2314 |

| C3 | Competition | 0.1811 |

| C7 | Economic | 0.1337 |

| C6 | Social | 0.1336 |

| C8 | Environment | 0.1150 |

| C2 | Supplier | 0.0885 |

| C4 | Consumption | 0.0628 |

| C1 | Company | 0.0539 |

Figure 5: SSCM criteria weights

Figure 5: SSCM criteria weights

External pressures from the government and competitors’ impact on SSCM for the automotive elastomer manufacturer in Thailand. There are some regulations and laws that control environmental problems that are caused by small particles and hazardous chemicals. The factory has followed the standards of the Ministry of Industry and certified ISO 14001:2015 for many years. The environmental issue is one of the company’s strategies. It has an operation plan to protect the environment such as use fewer chemical substances, reduce wastes and pollution, etc. These two factors are very important in leading the factory to the implementation of SSCM.

In the competitive market with rapid change, the factory needs to adjust itself to satisfy the target market, which is the global market. Most of the management team in this factory are foreigners who mainly focus on the global trend. Sustainable awareness for the manufacturer is currently in practice.

The economic issue is important for all profit organizations to survive. However, it should be balanced with social and environment issues. Every project about sustainable management in the factory has to be evaluated by feasibility analysis before implementing it.

The company implemented GSCM before desiring to switch to SSCM, so environmental concerns have existed in almost all of the supply chain. It has been certified to ISO14001:2015 for many years and still keeps track to reduce environmental problems of the factory.

The factory has a policy to select high-quality suppliers. These selected suppliers can help the company to improve the firm’s competitiveness across its supply chain. Reasonable price, high quality of raw materials, and fast response are the main factors of the selection. The existing suppliers rarely consider sustainability.

Most customers of the factory are foreign customers, who have less concern about the sustainability of the products. The company products are small parts for automotive manufacturers. Most of the automotive manufacturers are considering clean technology involving combustion in the engine, which is not related to the case study company’s products.

The company has the least weight of importance for SSCM. It operates for maximizing profits but the regulations, standards, laws, and stakeholders have forced the company to be concerned not only with profit but also the environment and social issues.

5. Conclusions

This research proposes a framework for SSCM that combines the whole supply chain. It is applied to the case study factory, which is an automotive elastomer producer. Criteria are collected and factors (government and competition), TBL factors (environment, rearranged into the framework, which is suitable for a manufacturer. Three main groups of criteria, which are external social, and economic), and internal factors (supplier, company, and customer) are reviewed. These factors are prioritized by the LFPP method, which has advantages over other methods. Government and competition are the most important criteria for the case study factory that force it to implement SSCM. Laws, regulations, and standards are carefully determined and set for the company to achieve. They are set has the highest priority for the company to achieve. Market and competitors are studied and the operation plan related to these criteria is defined. Environment, social, and economic criteria are the next factors that the factory is concerned about. They are considered to be at the same level of importance, which is balanced according to the concept of SSCM. Profit is still the goal that the factory wants to achieve, but there is also an environmental concern and the certified environmental standard to be satisfied. Moreover, the factory has plans for corporate social responsibility activities with the communities in its action plan. Existing SCM involves suppliers, the company, and customers. They are considered as the less important criteria. The proposals of actions of the case study factory was shown as an example for the other factories.

For future research, the level of SSCM performance in each practice tool should be evaluated to know the efficient tools for the implementation of SSCM.

Acknowledgment

This research was support financially by Ph.D. Scholarship and research unit funding from Thammasat University, Thailand.

- S. Mongkolchaichana, B. Phruksaphanrat, “A Comparison of Prioritization Methods for Green Supply Chain Management Criteria Evaluation,” 2019 IEEE 6th International Conference on Industrial Engineering and Applications, ICIEA 2019, (2015), 313–317, 2019, doi:10.1109/IEA.2019.8715191.

- S. Seuring, M. Müller, “From a literature review to a conceptual framework for sustainable supply chain management,” Journal of Cleaner Production, 16(15), 1699–1710, 2008, doi:10.1016/j.jclepro.2008.04.020.

- C.R. Carter, D.S. Rogers, “A framework of sustainable supply chain management: Moving toward new theory,” International Journal of Physical Distribution and Logistics Management, 38(5), 360–387, 2008, doi:10.1108/09600030810882816.

- M. Pagell, Z. Wu, “Building a more complete theory of sustainable supply chain management using case studies of 10 exemplars,” Journal of Supply Chain Management, 45(2), 37–56, 2009, doi:10.1111/j.1745-493X.2009.03162.x.

- M. Pakseresht, B. Shirazi, I. Mahdavi, N. Mahdavi-Amiri, “Toward sustainable optimization with stackelberg game between green product family and downstream supply chain,” Sustainable Production and Consumption, 23, 198–211, 2020, doi:10.1016/j.spc.2020.04.009.

- S.A.R. Khan, Z. Yu, H. Golpira, A. Sharif, A. Mardani, A state-of-the-art review and meta-analysis on sustainable supply chain management: Future research directions, Journal of Cleaner Production, 278, 2021, doi:10.1016/j.jclepro.2020.123357.

- J. Li, H. Fang, W. Song, “Sustainable supplier selection based on SSCM practices: A rough cloud TOPSIS approach,” Journal of Cleaner Production, 222, 606–621, 2019, doi:10.1016/j.jclepro.2019.03.070.

- L. Meherishi, S.A. Narayana, K.S. Ranjani, “Sustainable packaging for supply chain management in the circular economy: A review,” Journal of Cleaner Production, 237, 117582, 2019, doi:10.1016/j.jclepro.2019.07.057.

- J. Jemai, B. Do Chung, B. Sarkar, “Environmental effect for a complex green supply-chain management to control waste: A sustainable approach,” Journal of Cleaner Production, 277, 122919, 2020, doi:10.1016/j.jclepro.2020.122919.

- K. Sari, “A novel multi-criteria decision framework for evaluating green supply chain management practices,” Computers and Industrial Engineering, 105, 338–347, 2017, doi:10.1016/j.cie.2017.01.016.

- Ö. Uygun, A. Dede, “Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques,” Computers and Industrial Engineering, 102, 502–511, 2016, doi:10.1016/j.cie.2016.02.020.

- C. Wu, Y. Zhang, H. Pun, C. Lin, “Construction of partner selection criteria in sustainable supply chains: A systematic optimization model,” Expert Systems with Applications, 158, 2020, doi:10.1016/j.eswa.2020.113643.

- E. Mastrocinque, F.J. Ramírez, A. Honrubia-Escribano, D.T. Pham, “An AHP-based multi-criteria model for sustainable supply chain development in the renewable energy sector,” Expert Systems with Applications, 150, 2020, doi:10.1016/j.eswa.2020.113321.

- X. Yu, S. Zhang, X. Liao, X. Qi, “ELECTRE methods in prioritized MCDM environment,” Information Sciences, 424, 301–316, 2018, doi:10.1016/j.ins.2017.09.061.

- M. Alvandi, S. Fazli, L. Yazdani, M. Aghaee, “An Integrated MCDM Method in Ranking BSC Perspectives and key Performance Indicators (KPIs) ,” Management Science Letters, 2(3), 995–1004, 2012, doi:10.5267/j.msl.2012.01.024.

- M. Velasquez, P. Hester, “An analysis of multi-criteria decision making methods,” International Journal of Operations Research, 10(2), 56–66, 2013.

- C. Kahraman, B. Öztayşi, I. Uçal Sari, E. Turanoǧlu, “Fuzzy analytic hierarchy process with interval type-2 fuzzy sets,” Knowledge-Based Systems, 59, 48–57, 2014, doi:10.1016/j.knosys.2014.02.001.

- R.R. Kumar, S. Mishra, C. Kumar, “Prioritizing the solution of cloud service selection using integrated MCDM methods under Fuzzy environment,” Journal of Supercomputing, 73(11), 4652–4682, 2017, doi:10.1007/s11227-017-2039-1.

- S. Kubler, J. Robert, W. Derigent, A. Voisin, Y. Le Traon, “A state-of the-art survey & testbed of fuzzy AHP (FAHP) applications,” Expert Systems with Applications, 65, 398–422, 2016, doi:10.1016/j.eswa.2016.08.064.

- Y.M. Wang, Y. Luo, Z. Hua, “On the extent analysis method for fuzzy AHP and its applications,” European Journal of Operational Research, 186(2), 735–747, 2008, doi:10.1016/j.ejor.2007.01.050.

- K. Zhü, “Fuzzy analytic hierarchy process: Fallacy of the popular methods,” European Journal of Operational Research, 236(1), 209–217, 2014, doi:10.1016/j.ejor.2013.10.034.

- K. Rashidi, A. Noorizadeh, D. Kannan, K. Cullinane, Applying the triple bottom line in sustainable supplier selection: A meta-review of the state-of-the-art, Journal of Cleaner Production, 269, 2020, doi:10.1016/j.jclepro.2020.122001.

- C.S. Goh, H.Y. Chong, L. Jack, A.F. Mohd Faris, Revisiting triple bottom line within the context of sustainable construction: A systematic review, Journal of Cleaner Production, 252, 2020, doi:10.1016/j.jclepro.2019.119884.

- M.C. Arslan, H. Kisacik, “The Corporate Sustainability Solution: Triple Bottom Line,” The Journal of Accounting and Finance, (July), 18–34, 2017.

- H.L. Lam, W.P.Q. Ng, R.T.L. Ng, E.H. Ng, M.K.A. Aziz, D.K.S. Ng, “Green strategy for sustainable waste-to-energy supply chain,” Energy, 57, 4–16, 2013, doi:10.1016/j.energy.2013.01.032.

- J. Dai, F.L. Montabon, D.E. Cantor, “Reprint of ‘Linking rival and stakeholder pressure to green supply management: Mediating role of top management support,’” Transportation Research Part E: Logistics and Transportation Review, 74, 124–138, 2015, doi:10.1016/j.tre.2014.12.003.

- S.M. Lo, S. Zhang, Z. Wang, X. Zhao, “The impact of relationship quality and supplier development on green supply chain integration: A mediation and moderation analysis,” Journal of Cleaner Production, 202, 524–535, 2018, doi:10.1016/j.jclepro.2018.08.175.

- Stella Despoudi, Green supply chain, Elsevier Inc., 2020, doi:10.1016/b978-0-12-816449-5.00002-3.

- P. Du, X. Yang, L. Xu, Y. Tan, H. Li, “Green design strategies of competing manufacturers in a sustainable supply chain,” Journal of Cleaner Production, 265, 121853, 2020, doi:10.1016/j.jclepro.2020.121853.

- M. Kharaji Manouchehrabadi, S. Yaghoubi, J. Tajik, “Optimal scenarios for solar cell supply chain considering degradation in powerhouses,” Renewable Energy, 145, 1104–1125, 2020, doi:10.1016/j.renene.2019.06.096.

- L. Ren, S. Zhou, X. Ou, “Life-cycle energy consumption and greenhouse-gas emissions of hydrogen supply chains for fuel-cell vehicles in China,” Energy, 209, 118482, 2020, doi:10.1016/j.energy.2020.118482.

- J. hua Zhao, D. lin Zeng, L. ping Che, T. wei Zhou, J. yi Hu, “Research on the profit change of new energy vehicle closed-loop supply chain members based on government subsidies,” Environmental Technology and Innovation, 19, 100937, 2020, doi:10.1016/j.eti.2020.100937.

- H. Allaoui, Y. Guo, J. Sarkis, “Decision support for collaboration planning in sustainable supply chains,” Journal of Cleaner Production, 229, 761–774, 2019, doi:10.1016/j.jclepro.2019.04.367.

- Y. Cao, Y. Zhao, L. Wen, Y. Li, H. li, S. Wang, Y. Liu, Q. Shi, J. Weng, “System dynamics simulation for CO2 emission mitigation in green electric-coal supply chain,” Journal of Cleaner Production, 232, 759–773, 2019, doi:10.1016/j.jclepro.2019.06.029.

- H. Baligil, S.S. Kara, P. Alcan, B. Özkan, E. Gözde Alar, “A distribution network optimization problem for third party logistics service providers,” Expert Systems with Applications, 38(10), 12730–12738, 2011, doi:10.1016/j.eswa.2011.04.061.

- S. Wei, T. Ang, V.E. Jancenelle, “Willingness to pay more for green products: The interplay of consumer characteristics and customer participation,” Journal of Retailing and Consumer Services, 45(June), 230–238, 2018, doi:10.1016/j.jretconser.2018.08.015.

- Y. Wang, G. Hou, “A duopoly game with heterogeneous green supply chains in optimal price and market stability with consumer green preference,” Journal of Cleaner Production, 255, 120161, 2020, doi:10.1016/j.jclepro.2020.120161.

- X. Zhang, H.M.A.U. Yousaf, “Green supply chain coordination considering government intervention, green investment, and customer green preferences in the petroleum industry,” Journal of Cleaner Production, 246, 118984, 2020, doi:10.1016/j.jclepro.2019.118984.

- V. Carfora, C. Cavallo, D. Caso, T. Del Giudice, B. De Devitiis, R. Viscecchia, G. Nardone, G. Cicia, “Explaining consumer purchase behavior for organic milk: Including trust and green self-identity within the theory of planned behavior,” Food Quality and Preference, 76(March), 1–9, 2019, doi:10.1016/j.foodqual.2019.03.006.

- D. Chen, J. Ignatius, D. Sun, S. Zhan, C. Zhou, M. Marra, M. Demirbag, “Reverse logistics pricing strategy for a green supply chain: A view of customers’ environmental awareness,” International Journal of Production Economics, 217(May 2018), 197–210, 2019, doi:10.1016/j.ijpe.2018.08.031.

- H. Gholizadeh, H. Fazlollahtabar, “Robust optimization and modified genetic algorithm for a closed loop green supply chain under uncertainty: Case study in melting industry,” Computers and Industrial Engineering, 147(January 2019), 106653, 2020, doi:10.1016/j.cie.2020.106653.

- M. Ramirez-Peña, A.J. Sánchez Sotano, V. Pérez-Fernandez, F.J. Abad, M. Batista, “Achieving a sustainable shipbuilding supply chain under I4.0 perspective,” Journal of Cleaner Production, 244, 2020, doi:10.1016/j.jclepro.2019.118789.

- M.A.N. Agi, X. Yan, “Greening products in a supply chain under market segmentation and different channel power structures,” International Journal of Production Economics, 223(October 2019), 107523, 2020, doi:10.1016/j.ijpe.2019.107523.

- A.Y. Uemura Reche, O. Canciglieri Junior, C.C.A. Estorilio, M. Rudek, “Integrated product development process and green supply chain management: Contributions, limitations and applications,” Journal of Cleaner Production, 249, 119429, 2020, doi:10.1016/j.jclepro.2019.119429.

- T. Hadi, S.K. Chaharsooghi, M. Sheikhmohammady, A. Hafezalkotob, “Pricing strategy for a green supply chain with hybrid production modes under government intervention,” Journal of Cleaner Production, 268(December 2015), 121945, 2020, doi:10.1016/j.jclepro.2020.121945.

- P. Gautam, A. Kishore, A. Khanna, C.K. Jaggi, “Strategic defect management for a sustainable green supply chain,” Journal of Cleaner Production, 233, 226–241, 2019, doi:10.1016/j.jclepro.2019.06.005.

- A.C. Ng, Z. Rezaee, “Business sustainability factors and stock price informativeness,” Journal of Corporate Finance, 64(June), 101688, 2020, doi:10.1016/j.jcorpfin.2020.101688.

- S. Shoukohyar, M.R. Seddigh, “Uncovering the dark and bright sides of implementing collaborative forecasting throughout sustainable supply chains: An exploratory approach,” Technological Forecasting and Social Change, 158(April), 120059, 2020, doi:10.1016/j.techfore.2020.120059.

- C.R. Carter, P.L. Easton, “Sustainable supply chain management: Evolution and future directions,” International Journal of Physical Distribution and Logistics Management, 41(1), 46–62, 2011, doi:10.1108/09600031111101420.

- S. Seuring, M. Müller, “Core issues in sustainable supply chain management – A Delphi study,” Business Strategy and the Environment, 17(8), 455–466, 2008, doi:10.1002/bse.607.

- E. Koberg, A. Longoni, “A systematic review of sustainable supply chain management in global supply chains,” Journal of Cleaner Production, 207, 1084–1098, 2019, doi:10.1016/j.jclepro.2018.10.033.

- G. Yadav, S. Luthra, S.K. Jakhar, S.K. Mangla, D.P. Rai, “A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case,” Journal of Cleaner Production, 254, 120112, 2020, doi:10.1016/j.jclepro.2020.120112.

- M. Abdel-Basset, R. Mohamed, “A novel plithogenic TOPSIS- CRITIC model for sustainable supply chain risk management,” Journal of Cleaner Production, 247, 119586, 2020, doi:10.1016/j.jclepro.2019.119586.

- S. Yadav, S.P. Singh, “Blockchain critical success factors for sustainable supply chain,” Resources, Conservation and Recycling, 152(May 2019), 104505, 2020, doi:10.1016/j.resconrec.2019.104505.

- J.R. Brown, R.P. Dant, C.A. Ingene, P.J. Kaufmann, “Supply chain management and the evolution of the ‘Big Middle,’” Journal of Retailing, 81(2 SPEC. ISS.), 97–105, 2005, doi:10.1016/j.jretai.2005.03.002.

- M.S. Shaharudin, Y. Fernando, C.J. Chiappetta Jabbour, R. Sroufe, M.F.A. Jasmi, “Past, present, and future low carbon supply chain management: A content review using social network analysis,” Journal of Cleaner Production, 218, 629–643, 2019, doi:10.1016/j.jclepro.2019.02.016.

- D. Das, “The impact of Sustainable Supply Chain Management practices on firm performance: Lessons from Indian organizations,” Journal of Cleaner Production, 203, 179–196, 2018, doi:10.1016/j.jclepro.2018.08.250.

- J. Whitehead, C.J. MacLeod, H. Campbell, “Improving the adoption of agricultural sustainability tools: A comparative analysis,” Ecological Indicators, 111(June 2019), 106034, 2020, doi:10.1016/j.ecolind.2019.106034.

- C.A.L. Vanegas, G.A. Cordeiro, C.P. de Paula, R.E.C. Ordoñez, R. Anholon, “Analysis of the utilization of tools and sustainability approaches in the product development process in Brazilian industry,” Sustainable Production and Consumption, 16, 249–262, 2018, doi:10.1016/j.spc.2018.08.006.

- E. Dawkins, K. André, K. Axelsson, L. Benoist, Å.G. Swartling, Å. Persson, “Advancing sustainable consumption at the local government level: A literature review,” Journal of Cleaner Production, 231, 1450–1462, 2019, doi:10.1016/j.jclepro.2019.05.176.

- M. Rasti-Barzoki, I. Moon, “A game theoretic approach for car pricing and its energy efficiency level versus governmental sustainability goals by considering rebound effect: A case study of South Korea,” Applied Energy, 271(May), 115196, 2020, doi:10.1016/j.apenergy.2020.115196.

- J. Veldman, G. Gaalman, “On the design of managerial incentives for sustainability investments in the presence of competitors,” Journal of Cleaner Production, 258, 120925, 2020, doi:10.1016/j.jclepro.2020.120925.

- M. Mofidi Chelan, A. Alijanpour, H. Barani, J. Motamedi, H. Azadi, S. Van Passel, “Economic sustainability assessment in semi-steppe rangelands,” Science of the Total Environment, 637–638, 112–119, 2018, doi:10.1016/j.scitotenv.2018.04.428.

- Y. Zhao, Y. Tan, S. Feng, “Does reducing air pollution improve the progress of sustainable development in China?,” Journal of Cleaner Production, 272(September 2013), 122759, 2020, doi:10.1016/j.jclepro.2020.122759.

- B. Xia, A. Olanipekun, Q. Chen, L. Xie, Y. Liu, “Conceptualising the state of the art of corporate social responsibility (CSR) in the construction industry and its nexus to sustainable development,” Journal of Cleaner Production, 195, 340–353, 2018, doi:10.1016/j.jclepro.2018.05.157.

- E. Staniškienė, Ž. Stankevičiūtė, “Social sustainability measurement framework: The case of employee perspective in a CSR-committed organisation,” Journal of Cleaner Production, 188, 708–719, 2018, doi:10.1016/j.jclepro.2018.03.269.

- H. Ding, H. Huang, O. Tang, “Sustainable supply chain collaboration with outsourcing pollutant-reduction service in power industry,” Journal of Cleaner Production, 186, 215–228, 2018, doi:10.1016/j.jclepro.2018.03.039.

- S.A. Neves, A.C. Marques, J.A. Fuinhas, “Is energy consumption in the transport sector hampering both economic growth and the reduction of CO2 emissions? A disaggregated energy consumption analysis,” Transport Policy, 59(May), 64–70, 2017, doi:10.1016/j.tranpol.2017.07.004.

- M. Olfati, M. Bahiraei, F. Veysi, “A novel modification on preheating process of natural gas in pressure reduction stations to improve energy consumption, exergy destruction and CO2 emission: Preheating based on real demand,” Energy, 173, 598–609, 2019, doi:10.1016/j.energy.2019.02.090.

- S. Hendiani, H. Liao, R. Ren, B. Lev, “A likelihood-based multi-criteria sustainable supplier selection approach with complex preference information,” Information Sciences, 536, 135–155, 2020, doi:10.1016/j.ins.2020.05.065.

- J.M. Polimeni, R.I. Iorgulescu, A. Mihnea, “Understanding consumer motivations for buying sustainable agricultural products at Romanian farmers markets,” Journal of Cleaner Production, 184, 586–597, 2018, doi:10.1016/j.jclepro.2018.02.241.

- B. Hartl, T. Sabitzer, E. Hofmann, E. Penz, “‘Sustainability is a nice bonus’ the role of sustainability in carsharing from a consumer perspective,” Journal of Cleaner Production, 202, 88–100, 2018, doi:10.1016/j.jclepro.2018.08.138.

- J. Veldman, G. Gaalman, “On the design of managerial incentives for sustainability investments in the presence of competitors,” Journal of Cleaner Production, 258, 120925, 2020, doi:10.1016/j.jclepro.2020.120925.

- H. Dixon-Fowler, A. O’Leary-Kelly, J. Johnson, M. Waite, “Sustainability and ideology-infused psychological contracts: An organizational- and employee-level perspective,” Human Resource Management Review, 30(3), 100690, 2020, doi:10.1016/j.hrmr.2019.100690.

- Y.M. Wang, K.S. Chin, “Fuzzy analytic hierarchy process: A logarithmic fuzzy preference programming methodology,” International Journal of Approximate Reasoning, 52(4), 541–553, 2011, doi:10.1016/j.ijar.2010.12.004.

- L. Mikhailov, “A fuzzy approach to deriving priorities from interval pairwise comparison judgements,” European Journal of Operational Research, 159(3), 687–704, 2004, doi:10.1016/S0377-2217(03)00432-6.