The Effect of Different Starches in the Environmental and Mechanical Properties of Starch Blended Bioplastics

Volume 5, Issue 6, Page No 550-554, 2020

Author’s Name: Adriana C. Neves1,a), Tew Ming1, Marta Mroczkowska1, David Culliton2

View Affiliations

1Department of Science and Health, Institute of Technology Carlow, R93-A003, Ireland

2Department of Aerospace, Mechanical and Electronic Engineering, Institute of Technology Carlow, R93-A003, Ireland

a)Author to whom correspondence should be addressed. E-mail: nevesa@itcarlow.ie

Adv. Sci. Technol. Eng. Syst. J. 5(6), 550-554 (2020); ![]() DOI: 10.25046/aj050666

DOI: 10.25046/aj050666

Keywords: Bioplastic, Starch, Biomaterial

Export Citations

The problematic of plastic pollution in the world has led to an interest in the research and development of thermoset starch-protein blend bioplastics as a possible alternative for single use non-recyclable plastics. However, these bioplastics lack the physico-chemical characteristics that make them useful as a replacement for the currently used plastics. This work aims to assess what differences in the mechanical and environmental impact can be seen in the thermoset starch-protein blend bioplastics when different starches are used in their formulation. Rice, kuzu, corn, wheat and potato starches were used to generate bioplastics, and these were tested in terms of colour, lightness, roughness, chemical composition, moister content, water solubility and soil toxicity when degraded. Characteristics such as chemical composition, colour and moister content do not change significantly when the different starches are used, however it was possible to identify change in characteristics such as lightness, roughness, and water solubility of the bioplastics. Moreover, not only none of the bioplastics showed to be toxic to the soil when degraded, but also promoted the growth of the plant species tested. It was possible to conclude that the use of different starches in the formulation of thermoset starch-protein blend bioplastics allows the generation of bioplastics with different characteristics. This leads to an increase in applicability of theses bioplastics and consequently a higher positive impact in the environment.

Received: 27 August 2020, Accepted: 07 October 2020, Published Online: 20 November 2020

1. Introduction

Plastics usage is increasing exponentially, especially in the packaging industry, which is having devastating environmental impacts, globally. Increasing levels of consumer awareness, in terms of environmental sustainability and plastics-pollution, had created a demand for environmentally-friendly bioplastics, which decompose rapidly into water, carbon dioxide and biomass [1]. However, during events such as the current global pandemic, some members of the plastics industry have used the climate of fear and uncertainty to actively suspend or roll back hard-won environmental measures to reduce plastic pollution. As a result, there is an immediate and urgent need to increase the development and usage of alternative plastics, which have higher biodegradability and are made with fully organic components [2], typically referred to as bioplastics.

The term bioplastic was originally used to describe polymers which naturally biodegrade and compost. However, the term is now erroneously used by affected industry to additionally refer to biobased but either non-compostable plastics, or biodegradable plastics which require industrial processing to fully degrade [1]. In truth, only about 1 % of the current yearly production of plastic belongs to the bioplastic category and of those, only 43.2% are fully biodegradable. Moreover, many of the fully organic bioplastics generated do not have the mechanical properties equivalent to the currently used non-compostable plastics decreasing their applicability and industrial appeal [2]. For that reason, there is a compelling need to further develop bioplastics which are compostable, and which have no negative environmental impact.

Starch blended thermoset bioplastics are promising alternatives to petrol based plastics, due to lower production costs and better degradability [3]. In addition, blending starches with other biodegradable molecules and plasticisers can expand the applicability and improve the characteristics of thermoset starch-based bioplastics to different industries [4, 5]. The increasingly diverse blend-formulations have generated bioplastics with varied, tailorable, physico-chemical and mechanical properties, combined with the desired environmental impacts [3, 6].

These bioplastics will require more sustainable starch sources, as the most widely available are typically food-negative (ie. they derive from, or replace, in terms of agricultural production, product that is a current, critical human consumable). For example, potato, wheat and maize are the most widely produced starches in Europe, with 23.6 million tonnes of these starches produced in the EU in 2017 [7]. While in the United States of America more than 50% of starch production derives from corn [8]. However, alternative, gluten free starches, such as rice and kuzu starches, are increasing in popularity in the western world. The aim of this study is to compare the physico-chemical properties of five starch blended bioplastics as well as their post-degradation environmental impact. For this study, the starches used in the production of bioplastic were rice, kuzu, corn, wheat, and potato starch.

2. Materials and Methods

2.1. Materials

Sodium alginate LB (Duchefa Biochemie B.V., Netherlands), potato starch (MP BIomedicals LLC, Netherlands), food-grade wheat starch (Foo Lung Ching Kee, Hong Kong), food-grade rice flour (Foo Lung Ching Kee, Hong Kong), food-grade kuzu starch (Clearspring Ltd., London) produced in Japan and food-grade corn starch obtained from local grocery store (Aldi, Carlow) were used to generate bioplastics. Glycerol (EMPROVE®bio, Merck KGaA, Germany) was used as plasticiser. The Phytotoxkit was purchased from MicroBio Tests (Mariakerke, Gent, Belgium).

2.2. Preparation of bioplastics

The bioplastic-forming solution was prepared by dissolving 0.5g of sodium alginate LB into 20mL deionised water at room temperature with constant stirring speed of 595 rpm for at least 30 minutes or until a homogeneous aqueous solution was formed. In a beaker, 1g of starch and 1.5mL glycerol were mixed in 10mL of deionised water and added to the alginate solution. The solution was heated at 90°C with constant stirring at low agitation to avoid air bubbles formation for 20 minutes or until complete homogenisation was observed. The prepared solution was then poured into petri dish and kept at room temperature for 72 hours to dry.

2.3. Colour and brightness

The colour and transparency were read with a colorimeter (PCE-CSMI, PCE instruments, Meschede, Germany). The L*, a* and b* values were standardized for absolute white and black as per instrument instructions and then measured from four samples of each formulation and plotted accordingly.

2.4. Roughness test

The roughness of bioplastic samples was determined using SURFCOM130A roughness tester with a TS100 roughness tester sensor. The tester was calibrated with a standard of Ra=1,54µm before preforming the test. To determine the roughness sample was placed under the sensor and the placement of the sensor needle was adjusted with a knob on the tester. The test was performed in the center of five samples of the same material.

2.5. Fourier-transform infrared (FTIR) spectroscopy

The FTIR spectra were recorded as % transmission using a Spectrum 65 FT-IR Spectrometer (Perkin Elmer, Massachusetts, United States)

2.6. Soil toxicity

The soil toxicity was assessed using the Phytotoxkit instructions. In short, the water holding capacity was determined as per the instructions on the kit and the soil was pre-treated by degrading 10g of each bioplastic in soil samples weighing 100g over a 4 weeks period with daily hydration of the soil. The test plates were filled with 100g of test soil in the lower compartment, hydrated with 10ml of deionised water, a black filter paper was placed on top of the soil and 10 seeds of the same test plant were placed on top of the filter paper. The plants species used were garden cress (Lepidium sativum), and mustard (Sinapis alba). The control soil corresponds to soil where no bioplastics were degraded. The test containers were incubated at 25oC for 72h in darkness. The root length was measured using ImageJ software (U. S. National Institutes of Health, Bethesda, Maryland, USA).

2.7. Moister content and water solubility

According to Costa, et al. (2018), bioplastics with 2 cm of diameter were dried at 105°C for 24 hours or until ~±0.01g differences in weight were obtained. Four replicates of each formulation were operated in this study. The percentage of water lost in the system (moisture content) was calculated [9]. The samples were further used to determine water solubility based on method proposed by Costa, et al. (2012) and Fakhoury, et al. (2012). Method was slightly modified as samples are fully soluble in water after 1 hour. Instead of 24 hours, samples were immersed in 50mL deionised water for 30 minutes at low agitation (100rpm) then dried until ~±0.01g differences in weight were observed.

2.8. Statistical analysis of data

The results were analysed by one-way or two-way analysis of variance (ANOVA) with a significance level of P = 0.05 when appropriate. Independent sample t-test and Tukey’s multiple comparison tests were used, where applicable. The software employed for statistical analysis was Excel 2016 (Microsoft Excel 2016 MSO, California, USA) and SPSS Statistics (IBM SPSS Statistics 2015, New York, USA).

3. Results and discussion

3.1. Preparation of bioplastics

It was possible to generate five types of thermoset starch-protein blend bioplastic samples using the five different starches investigated (Figure 1). Bioplastics generated with different starches have been widely reported in literature, however, no published studies could be found which compared bioplastic generated from kuzu starch with bioplastics generated from rice, wheat, corn, and potato starch. The overall appearance of the kuzu-bioplastics was similar to other thermoset bioplastics reported in literature, with no detected starch-related plasticity differences. This was attributed to the same amount and type of plasticiser being used. This plasticiser component, used in the investigated formulations, has been reported to be the critical component in the plasticity of the final product, with no starch – bioplastic plasticity nexus observed [6, 10].

Figure 1: Thermoset starch blend bioplastics generated using rice (R), kuzu (K), corn (C), wheat (W) and potato (P) starches.

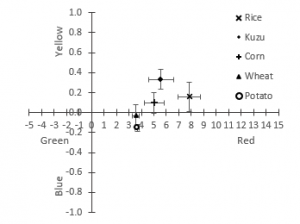

Figure 2:Colour a*; b* values of the bioplastics generated with rice, kuzu, corn, wheat, and potato starches. N=5 ± sd.

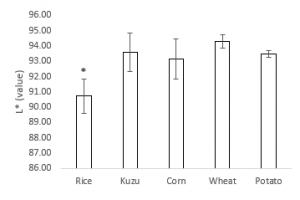

Figure 3: Brightness L* values of the bioplastics generated with rice, kuzu, corn, wheat, and potato starches. N=5 ± sd with * representing significantly different value.

3.2. Colour and brightness

Natural based bioplastics often display a yellow tone, though the addition of chemicals, or exposure to oxidation or bleaching processes, have been shown to produce a brighter and whiter tone. Unfortunately the effect of these processes on the environment has yet to be assessed [11, 12]. Alternatively, this intonation can be also affected by starch type, which is a more environmentally friendly way of generating brighter bioplastics with less of a yellow tone. For example, the colour and lightness analysis in this research demonstrated that bioplastics generated with rice, kuzu, and corn, have greater red/yellow components when compared to bioplastics generated from wheat and potato starches. Additionally, visual examination of the wheat- and potato- starch bioplastics indicated a less yellow tone (Figure 1). Moreover, the rice starch derived bioplastic had a significant lower brightness then all the other bioplastic tested (Figure 2). That might be linked with the higher red component in its colour. However, all of the bioplastics generated were considered to be white, according to the instrument guidelines, with the higher values corresponding to the rice derived bioplastic (L*90.73± 1.12; a*0.16± 0.15; b*7.84± 0.88).

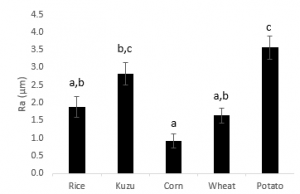

Figure 4: Roughness values of the surface in contact with air of thermoset starch-blend bioplastics generated with rice, kuzu, corn, wheat and potato starches. N=5 ± sd with different lower-case letters representing significantly different values.

3.3. Roughness Test

Polymer samples generated in the reported research were formed using flat moulds. As a result, one surface of the thermoset bioplastic films replicated the roughness of the mould. However, the surface in contact with the air acquired a natural texture. The texture of that surface was tested, and it was observed that the different starches used in the bioplastic formulation produced different surface roughness (Figure 4). The starches that lead to higher roughness were Potato and Kuzu with 3.55 ± 0.33 and 2.81 ± 0.31 Ra (μm) respectively and the starches that lead to smoother surface roughness are Wheat and Corn with 1.63 ± 0.21 and 0.92 ± 0.20 Ra (μm) respectively.

3.4. Fourier-transform infrared (FTIR) spectroscopy

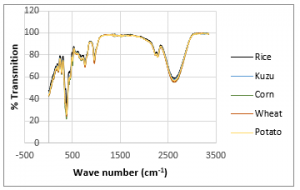

The purpose of FTIR analysis was to identify the presence of chemical bonds that were formed in bioplastics using the different starches. Figure 5 shows that the spectrums of all the bioplastics tested have similar profiles displaying the presence of O-H, C-H, C=O and C-O absorption peaks. This might be because although structurally the starches might have slightly different structures, their chemical composition is, overall, similar. Moreover, the profile of the bioplastics show similar chemical bonds to others starch-blend bioplastics reported in literature [13, 10, 11].

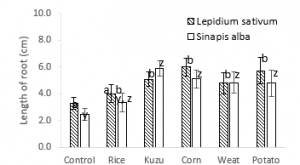

3.5. Soil toxicity

The effect of the degradation of the bioplastics with each starch in the growth of two plant species was tested with a soil toxicity test (Figure 6). The results show that there was no decrease in the growth of either Lepidium sativum or Sinapis alba after the degradation of any of the bioplastics tested in their growth soil. Contrarily, the bioplastics generated with kuzu, corn, wheat and potato starch showed a significant increase of growth in both plant species. The increase in plant growth in the soil after bioplastic degradation compared with the control soil might be related with the increase of Carbon (C) added to the soil after the bioplastics degradation. The addition of C to poor soils has been used for soil remediation showing to improve plant growth and crop productivity [14, 15]. The degradation of bioplastics with kuzu, corn, wheat or potato starches in carbon poor soils has the potential to improve their productivity.

Figure 5: Fourier transform infrared (FTIR) spectrums of the bioplastics generated with rice, kuzu, corn, wheat, and potato starch.

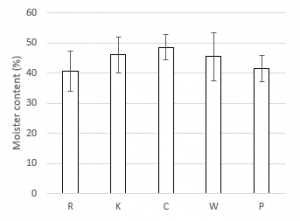

3.6. Moister content and water solubility

The moisture content of bioplastics can influence properties such as their compostability, elasticity, hydrophobicity among others and consequently influence their applicability [16]. For that reason, small changes in composition of the starch-based bioplastics might influence the time in which it fully composts. Composting time is of high importance for the applicability of bioplastics [2].

Figure 6: Growth of Lepidium sativum and Sinapis alba in soil where bioplastics with rice, kuzu, corn, wheat and potato starch were degraded. No bioplastic was degraded in the control soil prior to seeding. N=10 ± sd with different lower-case letters representing significantly different values.

Using the different starches tested in the bioplastic formulation does not seem to lead to significantly different moisture contents of the bioplastics, with all the formulations ranging from 41 ± 7 to 49 ± 4 % moisture content in the rice and corn based bioplastic respectively (Figure 7).

Figure 7: Moister content of thermoset starch-blend bioplastics generated with rice (R), kuzu (K), corn (C), wheat (W) and potato (P) starches. N=5 ± sd.

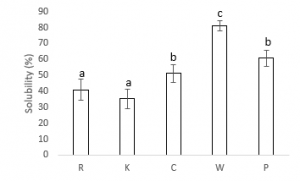

Similarly, understanding the effect of different starches in the solubility of the bioplastic is not only relevant industrially to assess potential applications of bioplastics but also needed to understand the impact of the bioplastics in the environment [2]. The solubility of the bioplastics tested ranged from 35 ± 6 to 81 ± 1% with the bioplastic sample generated with Kuzu being the least soluble and the one generated with wheat the most soluble. Moreover, there was not a significant difference found in the samples generated with potato, corn and rice starch or between the samples generated with Rice and Kuzu. Previous studies showed the link between starch concentration and solubility of the bioplastics [6], however, no previous studies have looked into a direct comparison of solubility of bioplastics when different starches are used in their formulation.

Figure 8: Solubility of thermoset starch-blend bioplastics in deionised water generated with rice (R), kuzu (K), corn (C), wheat (W) and potato (P) starches. N=5 ± sd with different lower-case letters representing significantly different values.

4. Conclusion

The generation of thermoset starch blend bioplastics using the five different starches tested lead to bioplastics that did not cause any toxicity to the growth of the plant species Lepidium sativum and Sinapis alba when degraded in the soil where they grew. Moreover, in all cases, except the rice-based bioplastic, their degradation lead to a significant increase of growth of these plant species.

The use of different starches led to the generation of bioplastics with similar FTIR profiles, as well as colour and water content. However, other characteristics differed depending on which starch was used for their formulation. Higher solubility was obtained when wheat starch was used. In opposition to rice and kuzu starches that can be used to obtain bioplastics with lower solubility rates.

Although in terms of colour all the bioplastics generated had a near-white colour, the brightness of these were dependent on the type of starch used. The rice, kuzu and corn starches lead to bioplastics with more red/yellow tones with rice derived bioplastic being the only one significantly different in terms of brightness.

In terms of roughness it was also possible to observe a difference between potato and kuzu based bioplastics with rougher surfaces in comparison with wheat and corn with smoother surfaces.

The results of this study show that there is a link between starch in the bioplastic composition and some of the properties tested. This is of high importance to industry when choosing formulations for the generation of organic thermoset bioplastics for different purposes.

Conflict of Interest

The authors declare no conflict of interest.

- M. Misra, V. Nagarajan, J. Reddy and A. Mohanty, “Bioplastics and green composites from renewable resources: where we are and future directions.,” 2011. In18th International Conference on Composite Materials 2011 August.

- A. Neves, M. Moyne, C. Eyre and B. Casey, “Acceptability and Societal Impact of the Introduction of Bioplastics as Novel Environmentally Friendly Packaging Materials in Ireland.,” Clean Technologies, 1, 127-143., 2, 2020. doi: https://doi.org/10.3390/cleantechnol2010009

- M. Rahmatiah Al Faruqy and K. Liew, Properties of Bioplastic Sheets Made from Different Types of Starch Incorporated With Recycled Newspaper Pulp, Journal of Transaction of Science and Technology. 3:257-264, 2016..

- N. Azahari, N. Othman and H. Ismail, “Biodegradation studies of polyvinyl alcohol/corn starch blend films in solid and solution media.,” Journal of Physical Science, 2(22), 15-31, 2011.

- K. Satyanarayana, G. Arizaga and F. Wypych, “Biodegradable composites based on lignocellulosic fibers—An overview,” Progress in polymer science, 9(34), 982-1021, 2009.

- R. Santana, R. Bonomo, O. Gandolfi, L. Rodrigues, L. Santos, A. dos Santos Pires, C. de Oliveira, R. Fontan and C. Veloso, “Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol.,” Journal of food science and technology, 1(55), 278-286., 2018. https://link.springer.com/article/10.1007/s13197-017-2936-6

- Starch Europe, “Starch.EU,” 2017. https://starch.eu/the-european-starch-industry/#data.

- Grand view research , “North America Organic Starch Market Analysis, By End-Use (Meat, Bakery, Confectionery and Dry Blends), By Ingredient (Corn, Potato, wheat), By Country, And Segment Forecasts, 2018 – 2025,” 2017. https://www.grandviewresearch.com/industry-

- M. J. Costa, A. M. Marques, L. M. Pastrana, J. A. Teixeira, S. M. Sillankorva and M. A. Cerqueira, “Physicochemical properties of alginate-based films: Effect of ionic,” Food Hydrocolloids, 81, 442-448, March 2018. doi: https://doi.org/10.1016/j.tplants.2018.11.010

- N. Ramakrishnan, S. Sharma, A. Gupta and B. Alashwal, “Keratin based bioplastic film from chicken feathers and its characterization.,” International journal of biological macromolecules, 111, 352-358., 2018.

- A. Cifriadi, T. Panji, N. Wibowo and K. Syamsu, “Bioplastic production from cellulose of oil palm empty fruit bunch.,” In IOP Conference Series: Earth and Environmental Science, 65(1), p. 012011, 2017.

- A. Low, “Decoloured bloodmeal based bioplastic,” (Doctoral dissertation, University of Waikato) Waikato, 2012.

- M. Ginting, M. Kristiani and Y. Siagian, “The effect of chitosan, sorbitol, and heating temperature bioplastic solution on mechanical properties of bioplastic from durian seed starch (Durio zibehinus),” Princ. author al. International Journal of Engineering Research and Application, 1(6), 33-38, 2016.

- X. Zhu, B. Chen, L. Zhu and B. Xing, “Effects and mechanisms of biochar-microbe interactions in soil improvement and pollution remediation: a review.,” Environmental Pollution, 227, 98-115, 2017. doi: https://doi.org/10.1016/j.envpol.2017.04.032

- R. Lalande, V. Furlan, D. Angers and G. Lemieux, “Soil improvement following addition of chipped wood from twigs.,” American journal of alternative agriculture, 13(3), 132-137., 1998. https://www.jstor.org/stable/44503064

- H. Karan, C. Funk, M. Grabert, M. Oey and B. Hankamer, “Green bioplastics as part of a circular bioeconomy.,” Trends in plant science,, 24(3), 237-249, 2019. doi: https://doi.org/10.1016/j.tplants.2018.11.010

Citations by Dimensions

Citations by PlumX

Google Scholar

Scopus

Crossref Citations

- Fahimeh Alsadat Seyedbokaei, Manuel Felix, Carlos Bengoechea, "Effect of Blending and Conjugation of Carboxymethyl Cellulose and Zein in Bioplastic Materials." Journal of Polymers and the Environment, vol. 33, no. 3, pp. 1308, 2025.

- Jiao Zhang, Ariane Perez-Gavilan, Adriana Cunha Neves, "Fortification of dairy-free yoghurt with bioactive protein from solid-state fermented brewers’ spent grain." Applied Food Research, vol. 5, no. 1, pp. 100833, 2025.

- Marta Mroczkowska, David Culliton, Kieran J. Germaine, Manasa Hegde, Edmond F. Tobin, Adriana Cunha Neves, "Valorisation of Tomato Waste as a Source of Cutin for Hydrophobic Surface Coatings to Protect Starch- and Gelatine-Blend Bioplastics." Biomass, vol. 4, no. 3, pp. 990, 2024.

- Subhankar Das, Manjula Ishwara Kalyani, "From trash to treasure: review on upcycling of fruit and vegetable wastes into starch based bioplastics." Preparative Biochemistry & Biotechnology, vol. 53, no. 7, pp. 713, 2023.

- Marta Mroczkowska, David Culliton, Kieran Germaine, Adriana Neves, "Comparison of Mechanical and Physicochemical Characteristics of Potato Starch and Gelatine Blend Bioplastics Made with Gelatines from Different Sources." Clean Technologies, vol. 3, no. 2, pp. 424, 2021.

- Robert Waraczewski, Siemowit Muszyński, Bartosz G. Sołowiej, "An Analysis of the Plant- and Animal-Based Hydrocolloids as Byproducts of the Food Industry." Molecules, vol. 27, no. 24, pp. 8686, 2022.

- Heni Radiani Arifin, Zain Adisti Mauliani, Putri Widyanti Harlina, Edy Subroto, Rossy Choerun Nissa, Asad Nawaz, " Characteristics of nanocomposite film based on elephant foot-yam starch ( Amorphophallus paeoniifolius ) with different nanocrystalline cellulose concentration ." International Journal of Food Properties, vol. 26, no. 2, pp. 3512, 2023.

No. of Downloads Per Month

No. of Downloads Per Country