Complex Order PIα+jβ Dγ+jθ Design for Surface Roughness Control in Machining CNT Al-Mg Hybrid Composites

Complex Order PI D

D Design for Surface Roughness Control in Machining CNT Al-Mg Hybrid Composites

Design for Surface Roughness Control in Machining CNT Al-Mg Hybrid Composites

Volume 5, Issue 6, Page No 299-306, 2020

Author’s Name: Ravi Sekhar1,a), Tejinder Paul Singh2, Pritesh Shah1

View Affiliations

1Symbiosis Institute of Technology (SIT), Symbiosis International (Deemed University) (SIU), Pune, 147001, India

2Department of Mechanical Engineering, Thapar Institute of Engineering & Technology, Patiala, 111045, India

a)Author to whom correspondence should be addressed. E-mail: ravi.sekhar@sitpune.edu.in

Adv. Sci. Technol. Eng. Syst. J. 5(6), 299-306 (2020); ![]() DOI: 10.25046/aj050636

DOI: 10.25046/aj050636

Keywords: Complex order controller, Fractional calculus, Fractional order controller, Nano composites, Carbon nanotubes, Fractional modeling, Bode diagram

Export Citations

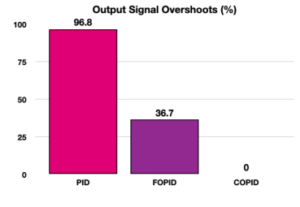

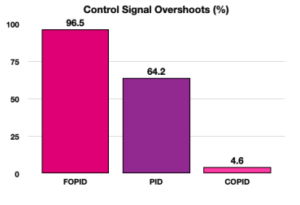

Accurate machining control is indispensable for the smart factories of tomorrow. Variations in controller responses may cause unacceptable process deviations during machining leading to productivity losses and possible damage. In the present work, a complex order PIα+jβDγ+jθ(COPID) controller was designed to effectively control surface roughness generation while machining CNT Al-Mg hybrid composites. Performance of the designed complex order controller was compared against the conventional PID and fractional order PID (FOPID) controllers for the machined surface roughness system. Output signal responses indicate that the complex order controller attains the desired surface roughness set point with zero percent overshoot in almost same settling time (46 sec) as PID (41 sec) and FOPID (46 sec) controllers. The PID and FOPID output signals registered overshoots of 96.8 % and 36.7 % respectively. Similarly, in case of control signals (feed rate) the COPID controller successfully minimised peak overshoot to 4.6 %; as compared to 64.2 % and 96.5 % in case of the PID and FOPID controllers respectively. The COPID controller was also effective in reducing its peak time response metric (2.001 % for control signal and no peak time for output signal due to zero overshoot). In comparison, the PID and FOPID controllers recorded higher response peak times (7 sec / 26 sec for the PID ouput/control and 5 sec / 7.84 sec for FOPID output/control signal responses). Overshoot elimination in output signal (surface roughness) is crucial for consistency of the machined surface quality. Similarly, overshoot minimisation in control signal (feed rate) is critical because excessive feed rate can damage the cutting tool, work piece, machinery and is a potential safety hazard for the machine operator as well. Hence, the COPID controller can be safely and extensively applied in smart industrial control systems of the future.

Received: 28 August 2020, Accepted: 01 November 2020, Published Online: 10 November 2020

1. Introduction

This paper is an extension of the work originally reported in the 2019 IEEE International Conference on Mechatronics, Robotics and Systems Engineering (MoRSE) [1]. In that work, firstly the multi input single output system of surface roughness generation during machining of the CNT Al-Mg composites was identified using the ARX and ARMAX model structures. Thereafter, the fractional order PID (FOPID) controller was designed to control the identified system at the desired set point (surface roughness). The authors reported that the ARMAX model based FOPID control exhibited better time domain characteristics as compared to the ARX model based FOPID controller design. The current work extends this work further to include complex order controller design to improve the time domain specifications corresponding to the machining variables not discussed in the previous work have also been included in the present study.

Metal matrix composites are new age materials finding new and varied applications due to their superior mechanical properties over conventional alloys [2]. Carbon nanotubes (CNT) in particular have attracted attention of researchers worldwide owing to the superior strengthening characteristics imparted by these nano sized particles to the base metal alloys [3]. Aluminum based alloy systems have almost a universal presence across industry sectors and products [4]. Combination of carbon nantubes and aluminum-magnesium alloys results in composites with superior mechanical characteristics.

Modeling and designing effective controllers is an important step towards automating the machining of these modern materials.

Generally, PID controllers find extensive applications due to their ease of implementation and maintenance in industrial systems. However, specialized machinery may require more sophisticated controllers having better design characteristics. Fractional order controllers offer a better design alternative because they have two more parameters to tune as compared to the traditional PID controllers [5, 6]. These controllers are based on fractional calculus, a branch of integral calculus that enables fractional orders of the model structure parameters. Fractional order PID controllers (FOPID) have been demonstrated to exhibit better performance characteristics in various application areas such as control systems, signal processing, medical research, material science and many more [7]–[10]. FOPID controllers prove to be more robust against system variations against their PID counterparts. Therefore, FOPID controllers are being increasingly preferred in more dynamic systems across industries [11]–[14]. Machining of complex materials like the metal matrix composites is one such example of a dynamic system; wherein the material composition is anisotropic and calls for a more robust controller architecture [6].

Complex order PID (COPID) controllers are the next step in the controller evolution [15]. They are an extension of the FOPID controllers just as the FOPID are extended versions of the PID controllers. The COPID have further two parameters to tune over the FOPID controllers. In the recent years, COPID controllers have been gradually attracting increasing investigations into their design and application aspects [16]–[18]. Khandani et al [19] designed a complex order controller for DC motors. Pinto and Carvalho [20] derived a complex order model for HIV infection drug resistance. Machado [18] optimized complex order controller for linear and non linear systems using genetic algorithm. Ayadi and Amairi [21] applied numerical optimization to tune complex order controller for a second order time delay resonant system. Hanif et al [22] implemented genetic algorithm for tuning of complex order controller design. Silva et al [23] applied complex order structure to model hexapod robot locomotion based on foot-ground transfer function. Jacob et al [15] reviewed frequency domain, time domain and stability aspects in complex order modeling of linear systems. Tare et al [24] compared integral, fractional and complex order controller performances for fractional order systems. Adams et al [25] determined the transfer function solution to the complex order differential equation. Shahiri et al [26] investigated robust control of a non linear fuel cell system using complex order architecture. From the literature review, it appears that the application of COPID controller in machining systems needs attention. The current work aims to bridge this gap.

The CNT Al-Mg composite experimental details may be referred to in the previous part [1] of the current work. It involved variation of the input machining parameters (cutting speed, feed and depth of cut) and data collection of the corresponding values of the machined surface roughness. Machining experiments were performed on a CNC turning center (Simple Turn 5057 Haas Automation) using chemical vapour deposition (CVD) coated tool inserts (Seco CNMG120408). Surface roughness was measured by a Handy Surf E-DTS570 tester. The best performing model structure (ARMAX) describing this machined surface roughness system in the previous work was adopted in the current study for the COPID and PID controller design. The FOPID controller time domain characteristics from the previous work [1] were referred to in the current work for comparisons with the COPID and PID controller responses. In the previous work, high peak overshoots were detected in output / control signal responses of the FOPID controller. The current study aimed to minimise / eliminate peak overshoots by employing COPID controller design. The following section details upon the design methodologies followed for the implementation of the PID, FOPID and COPID controllers in composite material machined surface roughness system.

Controller Design Methodology

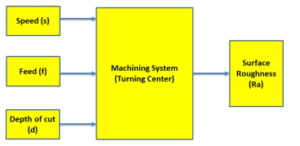

This section describes the design methodologies of the PID, FOPID and COPID controllers for the machined surface roughness system. All controllers were designed to attain output set point of 1 micron surface roughness. In machining, cutting speed is inversely related to surface roughness whereas depth of cut directly increases machined surface roughness levels. However, feed rate has the most significant effect on surface roughness generation [2]. Therefore, feed rate parameter was selected as the manipulated variable in the current study whereas cutting speed and depth of cut were maintained at their mid levels as per the experimental design [1]. Thus, all controllers were designed to control this multi input (cutting speed, feed, depth of cut) and single output (surface roughness) system as shwon in Figure 1.

Figure 1: Multi input single output system schematic for the nano composite machined surface roughness system

1.1. PID controller

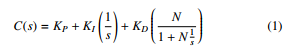

The PID controller has been widely implemented in industries since many years because of its simple structure and compatibility with the industrial automation software [27]. In the current work, Simulink block was utilised to implement PID controller for the machined surface roughness plant. The PID controller structure is given as follows:

where, KP is the proportional gain, KI is the integral gain, KD is derivative gain and N is the filter coefficient of derivative. The PID block was auto tuned in Simulink using the time domain approach.

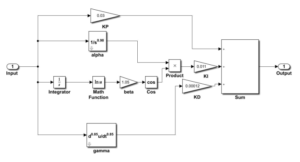

Figure 2: Complex PIα+jβDγ+jθ Controller Structure in Simulink

1.2. FOPID controller

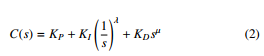

Fractional PID (FOPID) controller is an extension of the classical PID controller and is designed based on fractional calculus [28]. In this controller, the orders of integration and derivation are real numbers [29, 14]. The FOPID controller has the following controller structure:

where µ is the order of derivative and λ is the order of integration. There are five parameters in the fractional PID controller. This controller has the property of isodamping making it more robust against variations in the system parameters. The values of λ and µ were taken between 0 to 2 for the closed loop system to be stable.

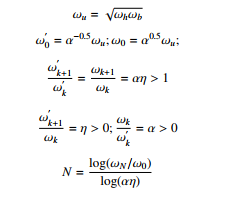

Following equations were employed to synthesise the fractional calculus for the fractional PID controller application:

where, N is the order of approximation, ωh and ωb are the

frequency bounds for approximation.

In the present work, FOMCON toolbox was used for implementation of FOPID and COPID controllers [12]. In this toolbox, Simulink blocks are available for various applications of fractional calculus. It can be used for designing controllers in continuous/discrete time scales, fractional order state space and many more. In FOPID design, the derivative action was considered zero (KD = 0 and µ = 0). The other gain parameters are taken from PID controller settings. Value of λ was selected based on the approach given by Shah and Agashe [29].

1.3. COPID controller

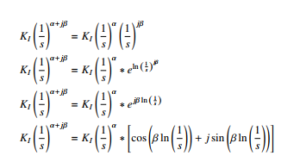

Complex order PID (COPID) controller idea originated from the 3rd generation of CRONE controller [30, 11]. COPID controller is similar to FOPID controller except that the orders of integration and derivation are complex instead of real numbers. The COPID controller has the following structure [16, 26].

![]()

The imaginary part of the above equation cannot be synthesised for time domain implementation of the system. Hence, for implementing the COPID controller in Simulink, imaginary part of the above equation was omitted [16].

The imaginary part of the above equation cannot be synthesised for time domain implementation of the system. Hence, for implementing the COPID controller in Simulink, imaginary part of the above equation was omitted [16].

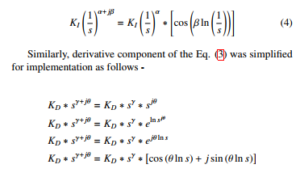

![]()

Combining Eq. (4) and (5), the COPID controller structure may be rewritten as

![]()

The COPID controller given in Eq. (6) was initially tuned by incorporating the reference values of FOPID controller and was further fine tuned based on the principles given in literature [31, 29]. The fine tuned COPID controller was implemented in Simulink

(Matlab) as shown in figure 2. The initial value of integer order integrator was assumed to be a small number during the controller implementation.

2. Results and Discussions

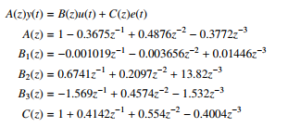

This section describes the different controller structures, output / control signal responses, time domain characteristics and Bode plot for the COPID controller. The discrete-time ARMAX model (order 3331) with 1 sec sample time from the previous work [1] was obtained as follows:

This model depicts the CNT Al-Mg composite machined surface roughness system considered in the current study. The PID controller applied on this model structure has the following structure:

![]()

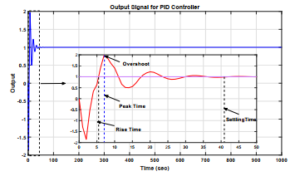

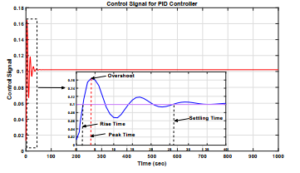

The output and control signal responses of this PID controller for a set point of 1 micron surface roughness are shown in Fig. 3 and Fig. 4 respectively.

Figure 3: PID controller output (surface roughness, µ) for the machined surface roughness system

Figure 4: PID control signal (feed rate, mm / rev) for the machined surface roughness system

Following is the structure of the FOPID controller applied to the composite machined surface roughness system –

![]()

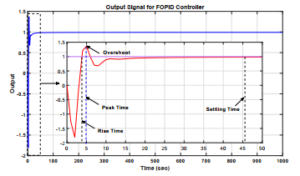

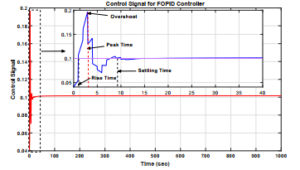

Fig. 5 and Fig. 6 depict the output and control signal plots for the FOPID controller set at 1 micron surface roughness output.

Figure 5: Fractional PID controller output (surface roughness, µ) for the machined surface roughness system

Figure 6: Fractional PID control signal (feed rate, mm / rev) for the machined surface roughness system

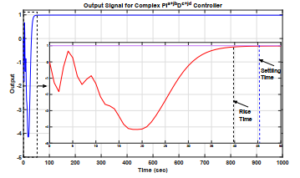

Figure 7: Complex PIα+jβDγ+jθ controller output (surface roughness, µ) for the machined surface roughness system

The complex order controller structure for the same system is shown below –

![]()

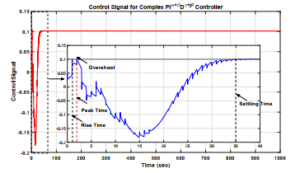

The output and control signal trends for the COPID controller are shown in Fig. 7 and Fig. 8 respectively.

Figure 8: Complex PIα+jβDγ+jθ control signal (feed rate, mm / rev) for the machined surface roughness system

Table 1: Time domain specifications of output signals

| PID | FOPID | COPID | |

| Rise Time (sec) | 5 | 3.8 | 39 |

| Peak Time (sec) | 7 | 5 | NA |

| Settling Time (sec) | 41 | 46 | 46 |

| Overshoot (%) | 96.8 | 36.7 | 0 |

| Table 2: Time d | omain specificat | ions of control sig | nals |

| PID | FOPID | COPID | |

| Rise Time (sec) | 2 | 1 | 1 |

| Peak Time (sec) | 4 | 2.924 | 2.001 |

| Settling Time (sec) | 26 | 7.844 | 34.38 |

| Overshoot (%) | 64.2 | 96.5 | 4.6 |

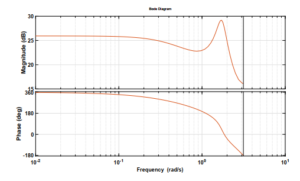

Figure 9: Bode plot for complex order controller

Figure 10: Output Signal Overshoots (%)

Table 1 shows the output signal (surface roughness) time domain specifications of the PID, FOPID and COPID controllers for the machined composite surface roughness system. The PID controller scores slightly better than the FOPID and COPID controllers in case of response settling time. PID also scores significantly better than the COPID controller in terms of the rise time. FOPID controller attains the least rise time. However, the COPID controller positively removes peak overshoot from the output signal. The other two controllers have high overshoots in their respective output signal responses. High overshoot in the surface roughness output is undesirable from quality perspective. Generally, critical industrial components require tight dimensional and surface roughness tolerances. Hence, for such cases of precision manufacturing, complex troller does perform better than the COPID for settling time. In the current study, control signals correspond to feed rate manipulation in the actual machining systems. High overshoots in feed rate settings may lead to cutting tool damage / breakage, machine tool chatter and possible safety hazard for the machinist. Therefore, minimisation of peak overshoots in feed rate manipulation is a critical machining requirement being fulfilled by the complex order PID controller. Fig. 9 and 10 give visual representations of

Figure 11: Control Signal Overshoots (%)

3. Conclusions

The current work is an extension of the preliminary study reported in the 2019 IEEE International Conference on Mechatronics, Robotics and Systems Engineering (MoRSE) [1]. The preliminary study involved system identification and FOPID control of surface roughness evolution in machining of CNT Al-Mg composite materials. The ARMAX model structure controlled by the FOPID controller produced best output signal responses as reported in the maiden paper [1]. The current study expanded that work by including PID and COPID controller designs on the best performing ARMAX model structure determined in the previous work. All three controllers’ responses were compared in terms of time domain specifications of the respective output and control signal responses. The current work also included analysis of the output signal trends for the said controllers (which was not considered in the preliminary study). The COPID controller conclusively demonstrated its ability to minimise and eliminate peak overshoot percentages in the control signal (feed rate) and output signal (surface roughness) responses respectively. The other two controllers (PID and FOPID) proved effective in reducing other time domain metrics viz. rise, peak and settling times. However these controllers were unable to stem the peak overshoots to minuscule levels. It is absolutely important to minimise and possibly eliminate the control/output signal overshoots to avoid the adverse affects of such overshoots on the machining process and product quality. This work establishes that the complex order PID controllers can be safely and widely adopted towards effective control of nano composite manufacturing systems for high productivity.

- R. Sekhar, T. Singh, P. Shah, “ARX/ARMAX Modeling and Fractional Or- der Control of Surface Roughness in Turning Nano-Composites,” in 2019 International Conference on Mechatronics, Robotics and Systems Engineering (MoRSE), 97–102, IEEE, 2019, doi:10.1109/MoRSE48060.2019.8998654.

- R. Sekhar, T. Singh, “Mechanisms in turning of metal matrix composites: a review,” Journal of Materials Research and Technology, 4(2), 197–207, 2015, doi:https://doi.org/10.1016/j.jmrt.2014.10.013.

- R. Sekhar, T. Singh, “Determination of Johnson Cook Parameters in Turning of Micro and Nano Reinforced Aluminum Composites using Trust Region Reflec- tive Algorithm,” International Journal of Innovative Technology and Exploring Engineering, 8(12), 1712–1716, doi:10.35940/ijitee.L3183.1081219.

- V. S. Jatti, R. Sekhar, R. Patil, “Study of ball nose end milling of LM6 al alloy: Surface roughness optimisation using genetic algorithm,” Int. J. Eng. Technol, 5, 2859–65, 2013, doi:http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1. 1.411.1573&rep=rep1&type=pdf.

- I. Podlubny, “Fractional-order systems and fractional-order controllers,” In- stitute of Experimental Physics, Slovak Academy of Sciences, Kosice, 12(3), 1–18, 1994, doi:http://people.tuke.sk/igor.podlubny/pspdf/uef0394.pdf.

- R. Sekhar, T. Singh, P. Shah, “Micro and Nano Particle Composite Machining: Fractional Order Control of Surface Roughness,” in Third International Con- ference on Powder, Granule and Bulk Solids: Innovations and Applications PGBSIA 2020 February 26-28, 2020, 35, 2020, doi:https://www.pgbsia.com/ wp-content/uploads/Conference-Proceedings-PGBSIA-2020.pdf#page=40.

- P. Shah, R. Sekhar, S. Agashe, “Application of Fractional PID Controller to Single and Multi-Variable Non-Minimum Phase Systems,” International Journal of Recent Technology and Engineering, 8(2), 2801–2811, 2019, doi: 10.35940/ijrte.b2805.078219.

- P. Shah, R. Sekhar, “Closed Loop System Identification of a DC Motor us- ing Fractional Order Model,” in 2019 International Conference on Mecha- tronics, Robotics and Systems Engineering (MoRSE), 69–74, IEEE, 2019, doi:https://doi.org/10.1109/MoRSE48060.2019.8998744.

- P. Shah, S. Agashe, “Design and optimization of fractional PID con- troller for higher order control system,” in International conference of IEEE ICART, 588–592, 2013, doi:https://www.semanticscholar.org/paper/ Design-and-Optimization-of-Fractional-PID-for-Order-Shah-Agashe/ 6e32b76ffe9609e0423e062b8aedd87361dedd4c.

- R. Bhimte, K. Bhole, P. Shah, “Fractional Order Fuzzy PID Controller for a Rotary Servo System,” in 2018 2nd International Conference on Trends in Electronics and Informatics (ICOEI), 538–542, IEEE, 2018, doi:https: //doi.org/10.1109/ICOEI.2018.8553867.

- S. Das, Functional fractional calculus, Springer Science & Business Media, 2011, doi:https://doi.org/10.1007/978-3-642-20545-3.

- A. Tepljakov, “FOMCON: fractional-order modeling and control toolbox,” in Fractional-order Modeling and Control of Dynamic Systems, 107–129, Springer, 2017, doi:https://doi.org/10.1007/978-3-319-52950-9 6.

- P. Shah, S. Agashe, “Design of controller for a higher order system without using model reduction methods,” Progress in Fractional Differentation and Applications, 3, 289–3004, 2017, doi:http://dx.doi.org/10.18576/pfda/030405.

- M. F. Silva, J. T. Machado, R. S. Barbosa, “Complex-order dynamics in hexapod locomotion,” Signal processing, 86(10), 2785–2793, 2006, doi: https://doi.org/10.1016/j.sigpro.2006.02.024.

- A. V. Tare, J. A. Jacob, V. A. Vyawahare, V. N. Pande, “Design of novel optimal complex-order controllers for systems with fractional-order dynamics,” International Journal of Dynamics and Control, 7(1), 355–367, 2019, doi:https://doi.org/10.1007/s40435-018-0448-5.

- J. L. Adams, T. T. Hartley, L. I. Adams, “A solution to the fundamental linear complex-order di_erential equation,” Advances in Engineering Software, 41(1), 70–74, 2010, doi: https://doi.org/10.1016/j.advengsoft.2008.12.014.

- M. Shahiri, A. Ranjbar, M. R. Karami, R. Ghaderi, “Robust control of nonlinear PEMFC against uncertainty using fractional complex order control,” Nonlinear Dynamics, 80(4), 1785–1800, 2015, doi:https://doi.org/10.1007/s11071-014-1718-1.

- K. J. Åstr¨om, P. Eykho_, “System identification—a survey,” Automatica, 7(2), 123–162, 1971, doi:https://doi.org/10.1016/0005-1098(71)90059-8.

- P. Shah, S. Agashe, “Review of fractional PID controller,” Mechatronics, 38, 29–41, 2016, doi:https://doi.org/10.1016/j.mechatronics.2016.06.005.

- P. Shah, S. Agashe, “Experimental Analysis of Fractional PID Controller Parameters on Time Domain Specifications,” Progress in Fractional Di_erentiation and Applications, 3, 141–154, 2017, doi:http://dx.doi.org/10.18576/pfda/030205.

- P. Lanusse, A. Oustaloup, B. Mathieu, “Third generation CRONE control,” in Proceedings of IEEE Systems Man and Cybernetics Conference-SMC, volume 2, 149–155, IEEE, 1993, doi:https://doi.org/10.1109/ICSMC.1993.384864.

- K. H. Ang, G. Chong, Y. Li, “PID control system analysis, design, and technology,” IEEE transactions on control systems technology, 13(4), 559–576, 2005, doi: https://doi.org/10.1109/TCST.2005.847331.

- M. F. Silva, J. T. Machado, R. S. Barbosa, “Complex-order dynamics in hexapod locomotion,” Signal processing, 86(10), 2785–2793, 2006, doi: https://doi.org/10.1016/j.sigpro.2006.02.024.

- A. V. Tare, J. A. Jacob, V. A. Vyawahare, V. N. Pande, “Design of novel optimal complex-order controllers for systems with fractional-order dynam- ics,” International Journal of Dynamics and Control, 7(1), 355–367, 2019, doi: 10.1007/s40435-018-0448-5.

- J. L. Adams, T. T. Hartley, L. I. Adams, “A solution to the fundamental linear complex-order differential equation,” Advances in Engineering Software, 41(1), 70–74, 2010, doi: 10.1016/j.advengsoft.2008.12.014.

- M. Shahiri, A. Ranjbar, M. R. Karami, R. Ghaderi, “Robust control of non- linear PEMFC against uncertainty using fractional complex order control,” Nonlinear Dynamics, 80(4), 1785–1800, 2015, doi: 10.1007/ s11071-014-1718-1.

- K. J. Åstro¨m, P. Eykhoff, “System identification—a survey,” Automatica, 7(2), 123–162, 1971, doi:https://doi.org/10.1016/0005-1098(71)90059-8.

- P. Shah, S. Agashe, “Review of fractional PID controller,” Mechatronics, 38, 29–41, 2016, doi: 10.1016/j.mechatronics.2016.06.005.

- P. Shah, S. Agashe, “Experimental Analysis of Fractional PID Controller Parameters on Time Domain Specifications,” Progress in Fractional Differenti- ation and Applications, 3, 141–154, 2017, doi: 10.18576/pfda/ 030205.

- P. Lanusse, A. Oustaloup, B. Mathieu, “Third generation CRONE control,” in Proceedings of IEEE Systems Man and Cybernetics Conference-SMC, volume 2, 149–155, IEEE, 1993, doi: 10.1109/ICSMC.1993. 384864.

- K. H. Ang, G. Chong, Y. Li, “PID control system analysis, design, and technol- ogy,” IEEE transactions on control systems technology, 13(4), 559–576, 2005, doi: 10.1109/TCST.2005.847331.