Investigation of Dielectric Properties of Indigenous Blended Ester oil for Electric System Applications

Volume 5, Issue 5, Page No 669-673, 2020

Author’s Name: D.M. Srinivasa1,a), Usha Surendra2, V.V. Pattanshetti3

View Affiliations

1Department of E&E Engineering, PES College of Engineering, Mandya, 571401, India

2Department of E&E Engineering, School of Engineering & Technology, Christ (Deemed to be University), Bangalore – 560074, India

3Central Power Research Institute, Bangalore, 560074, India

a)Author to whom correspondence should be addressed. E-mail: srinivasa.dm@res.christuniversity.in, dmsrinivasa.pesce@gmail.com

Adv. Sci. Technol. Eng. Syst. J. 5(5), 669-673 (2020); ![]() DOI: 10.25046/aj050582

DOI: 10.25046/aj050582

Keywords: Antioxidants, Degasification, Indigenous oil

Export Citations

The insulation condition of a transformer decides the longevity of the equipment. The unpredicted failure of power transformer will lead to major disaster in the distribution network and it affects both environment and public safety. Nowadays synthetic oil and natural esters are alternatives to transformer oil because of the biodegradable nature. In this paper, investigations were carried out to study the performance of the blended ester. The different properties investigated were viscosity, breakdown voltage, flash point, dielectric dissipation factor and moisture content. Comparisons of the properties were made between mineral oil, vegetable oil without additives and with additives. Further Investigation was carried out to study the impact of antioxidants and degasification. The results indicated that the addition of antioxidants and degasification of the vegetable oil improve significantly its voltage withstanding capacity. The Indigenous oil is code named as DM; Indigenous oil with DBPC is codenamed as DM1, Indigenous oil with BHA is codenamed as DM2. The results have been tabulated and found to be satisfactory.

Received: 12 August 2020, Accepted: 19 September 2020, Published Online: 05 October 2020

1. Introduction

The life of insulating medium is investigated by comparing the Breakdown strength and Viscosity of different oil in its pure form with that of the contaminated oil and to find the alternative for mineral oil. The presence of moisture content in the mineral oil compared to vegetable oil would be the main cause for failure of insulation. Vegetable oils which are reliable, cost-effective and environmentally friendly [1]. The evaluation of dielectric properties of Nomex-910 and thermally upgraded Kraft (TUK) paper is being investigated in soya-based natural ester oil by performing accelerated thermal ageing (at 1200C, 1500C and 1800C as per modified ASTM D1934) [2].

The waste cooking oil (WCO) acts as a potential alternative to the existing transformer insulating oil. The use of WCO promotes the optimal consumption of plant-based resources and more efficient waste management. Trans esterification method is performed to eliminate the free fatty acids in the WCO and to reduce viscosity. The trans esterification process is based on the chemical modification reaction between WCO, methyl alcohol (methanol) and sodium hydroxide (NaOH) catalyst lye that produces waste cooking oil methyl ester (WCOME). Chemical and electrical properties of the developed WCOME are compared with the existing WCO [3]. The analysis has been carried out to investigate the critical parameters in different vegetable oil before and after the inclusion of an aging derivative of 2–furfuraldehyde (2-FAL) [4]. The survey has been made to present recent research progress and also for future research. The research scenarios related to the performance of ester fluids versus mineral oils, miscibility, and retro filling of insulating fluids are discussed along with challenges and future aspects on the investigation to enhance the knowledge of ester fluids [5].

The impact of electrical and physicochemical properties of different vegetable oils with different ageing has been studied [6]. Due to lack of oxidative stability, the vegetable oils are less exposed as dielectric in transformer application [7]. The dielectric properties and partial discharge of mineral oil, natural ester and FR3 have been investigated. The suitability in practical use of oils is verified with impregnation of pressboard insulation [8]. The dielectric property of pongamia pinnata oil (PPO) under thermally aged condition has been investigated. [9]. Comparative study of five different types of natural ester liquid under a variation of temperature has been made with respect to different properties. [10]. A study has been carried out to explore the performance of coconut oil as an insulator [11]. Investigation of different properties of Palm Oil (PO) and Coconut Oil (CO) has been carried out under open thermal ageing condition [12]. The analysis of breakdown strength and physical characteristics of extra virgin olive oil and castor oil under unaged and thermally aged conditions is performed and compared the results with mineral oil with respect to same aging process [13]. The natural ester-based oils are investigated to analyse the suitability of it as better insulating medium with respect to their properties. Further analysis is carried out to on the fatty acid content and cost of vegetable oil [14]. Different vegetable oils and their blends are considered to investigate their dielectric properties with thermal ageing for about120 hours [15]. Neem oil, sunflower oil and mahua oil are blended with antioxidants plus nano powders to measure various properties. To minimize the oxidation stability, Synthetic antioxidants such as Beta Carotene and TBHQ (Tert-Butyl Hydro Quinone) and selenium are preferred as natural antioxidants [16].

Many a times vegetable oils develop bad odour due to oxidation and also rendered unfit for edible applications. These oils can be used effectively reconditioned for applications such as dielectrics by removal of the undesirable products.

In this research paper experiments have been carried out to determine the physical and electrical properties of Indigenous oil which is initially rancid in nature. This oil has chemically treated to bring to status of edible oil and then investigated for different properties. In this paper, section I explained the introduction and its related works. Section II, indicated the methodology and experimental procedure. Results and discussions have been given in section III and Section IV reserved for conclusion.

Experimental Procedure

The different physical and electrical characteristics of vegetable oil require special considerations. Due to the presence of oxygen, the degradation of the fluid takes place. So, the dielectric properties are investigated for the smooth operation of transformers.

2.1. Experimental Procedure

The process of refinement adopted in the present work has been given below.

- The vegetable oil was mixed with hot water (70˚C), shaken for 10 minutes and allowed to cool for 30 minutes. The separated supernatant was again mixed with hot water (60-70˚C) and stirred for 30 minutes. This process helped to remove the gums, waxes and other water soluble components from the oil.

- Removal of free acids: Oil has been mixed with equal volume of 5% Sodium Hydroxide solution and stirred for 20 minutes by treating with dilute caustic soda (5% solution). Free fatty acids reacted with caustic soda result in sodium soap. These acids can be coagulated by heating. Allow the soaps to settle and separate them from filtration.

- Removal of bad odour: Vegetable oil has bubbled with steam in the oil for 1 hour to remove the low volatile oxidised products. Supernatant oil layer has been taken out, leaving behind the condensed water.

- Removal of Pigments and Polar contaminants: Oil has been subsequently passed through an adsorbent column of korvi earth wherein pigments and other polar contaminants will be adsorbed leaving the clean oil ready for use as dielectric fluid.

- Removal of dissolved oxygen and removal of trace moisture and other polar components: Oil has been bubbled with hot nitrogen gas in a controlled manner to strip any dissolved oxygen, carbon dioxide, traces of moisture for almost 24 hours. The process has been used to reduce the moisture.

- Sample preparation: Mineral oil (Electrol-IS335), Indigenous oil and a quantity of 1108 ml of Indigenous oil mixed with 9 grams of DBPC (2,6-di-tert-butyl-p-cresol) and also 9 grams of BHA(Butylated hydroxyl Anisole) is mixed with 1108ml of Indigenous oil is magnetically stirred to ensure complete dissolution are the samples considered for investigation of physical and electrical properties. Samples prepared with indigenous oil without antioxidant has been named as DM, the indigenous oil with DBPC has named as DM-1and the indigenous oil with BHA has named as DM-2.

The following test has been conducted to investigate both electrical and physical properties.

2.2. Breakdown Voltage Conduction Test (BDV)

As per IEC standard, electrodes of spherical in shape has been placed at a distance of 2.5 mm and the liquid specimen filled test cup were used to carry out the test as per Figure 1. Repeatedly conducted the test for 6 times and noted the values for analysis purpose. AC high voltage supply varied gradually till its breakdown at a step of 2kV/sec. BDV test has been conducted as per IEC 60156 standards.

Figure 1: (a). Circuit diagram for breakdown voltage measurement (b) Breakdown voltage test.

2.3. Kinematic Viscosity

Cannon-Fensken viscometer (Figure 2 and Figure 3) is used for the viscosity test. The test specimen has been filled in the tube up to the level indicated in the bulb. Viscosity has been calculated by considering the calibration constant.

Kinematic Viscosity (centistokes-cSt) = (time in seconds) × (viscometer constant)

2.4. Flash Point

The ground level temperature at which flame causes the fire in the form of a flash under specified conditions is called the flash point. Flash point is measured using PENSKY MARTEN’S closed setup as shown in Figure 4. The procedure to identify the flash point has given as follows:

- To heat the oil, the liquid has been filled up to the specified level given in the flash point apparatus.

- External fire has been injected at regular time interval until the flash over occurs. Note the temperature at which flash occurs. Flash point=Recorded temperature at which flash occurs.

Figure 2: Cannon –Fensken viscometer

Figure 3: Viscometer tube.

Figure 4: Pensky martens.

2.5. Dielectric Dissipation factor

Dielectric dissipation factor is measured as per IEC-60247 standards using Eltel model-ADTR-2K Capacitance – Tan δ bridge.

2.6. Degasification Method

Oxidation stability is important to measure the quality and life time of liquid dielectrics. Moisture in oil will degrade the insulation. Transformer failure occurs due to the presence of moisture as well as heat, oxidation, and electrical stresses. Moisture has a significant effect on the dielectric strength. Improvement in the oxidation stability and reduction of moisture content level is achieved by adding antioxidants and also by degasification.

Indigenous oil with DBPC (DM-1) and BHA (DM-2) is considered for degasification with nitrogen gas to remove oxygen and also to reduce moisture content present in the Indigenous oil to investigate improvement in breakdown voltages.

3. Result and Discussion

Experiments have been conducted on DM, DM-1 and DM-2 to identify their breakdown voltage, viscosity, flash points, dielectric dissipation factor and moisture content.

3.1. Standard Values

The ranges of the various characteristics of liquid dielectrics as per IEC62770 standards, has been indicated in the table 1. After experimentation, results of MO, DM, DM-1and DM-2 has been compared with standard values and found out that, the values comes under with in the acceptance limits of IEC62770-2013.

Table 1: IEC62770-2013 standard ranges of liquid dielectrics

| Characteristics | Acceptable limits | Mineral oil (MO) | Indigenous oil without Antioxidants(DM) | Indigenous oil with DBPC(DM-1) | Indigenous oil with BHA (DM-2) |

| Breakdown voltage, kV | 30(min) | 32 | 29 | 37 | 43 |

| Dielectric dissipation factor | 0.05(max) | 0.00064 | 0.038 | 0.034 | 0.0511 |

| Kinematic Viscosity, cSt @40 ˚C | 50(max) | 13.74 | 46 | 44 | 42 |

| Water content, ppm | 200(max) | 11 | 501 | 454 | 340 |

| Flash point, ˚C | 250(min) | 152 | 256 | 251 | 245 |

Figure 5: BDV Values of oils.

From Fig 5. BDV of DM-1 is higher than MO and DM. This indicates breakdown voltage of DM-2 is more than MO and DM and DM-1. As the BDV of Indigenous oil is high, this results in higher breakdown strength of Indigenous oil than MO.

Figure 10 indicated the Dielectric dissipation factor of MO, DM and DM-1 oils and the value has been observed and found out that it has well within the 0.05 of standard limits. But the DDF of DM-2 is slightly more than the standard limits. The desired low dissipation factor of oil has been achieved and also it indicated the low power factor.

Figure 6: Comparative chart of dielectric dissipation factor of oils.

Figure 7: Viscosity of oils

From Figure 7 Viscosity of both DM, DM-1and DM-2 is higher than MO. For better cooling capability, the insulating liquid should have low viscosity. Still the value of viscosity of DM, DM-1and DM-2 will be reduced by reducing the moisture content.

Figure 8: Water content of oils

From Figure 8 Water content is more in DM, DM-1 and DM-2 compared to MO. Reducing the water content in the oil enhances the properties, can be reached by adding antioxidants and also by degasification.

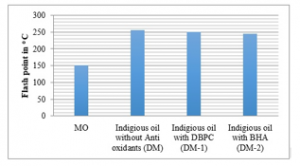

Figure 9: Flash point of oils.

From Figure 9. Flash points of DM, DM-1and DM-2 is very much higher than MO. This indicates higher withstanding capacity of Fire.

3.2. Improvement in BDV Values

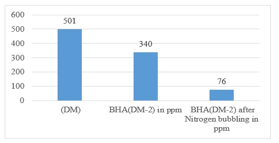

Figure 10 indicates that there is a reduction in the moisture content of DM-2 after nitrogen bubbling.

Figure 10: Reduction of Moisture content in DM-2(ppm)

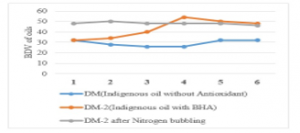

Figure 11: Comparison of breakdown voltage of oils

Figure 11 and 12 indicates that average breakdown voltage is increased in DM-1 after nitrogen bubbling compared with DM (Indigenous oil without Antioxidant) and DM-1(Indigenous oil with DBPC)

Figure 12: Average breakdown voltage of oils

Figure 13: Comparison of breakdown voltage of oils

Figure 14: Average breakdown voltage of oils

Figure 13 &14 indicates that average breakdown voltage is increased in DM-2 after nitrogen bubbling compared with DM (Indigenous oil without Antioxidant) and DM-2(Indigenous oil with BHA).

4. Conclusion

Insulation property will be acted as the prime active portion of the high voltage equipment’s. The cooling of the transformer depends on the viscosity of the insulating oil and governed by convection. Higher the flash point which in turn reduces the risk of transformer explosions and fire catching criteria and protect the environment.

After adding antioxidants, voltage withstanding capacity of Indigenous oil has been enhanced. It was observed that flash point of the DM, DM-1 and DM-2 is higher than that of mineral oil. In the similar manner, break down voltage (BDV), Dielectric Dissipation factor and Viscosity of DM, DM-1and DM-2 has been observed and found out that their values were well within the range of IEC62770-2013 standard values.

Further Breakdown voltage is enhanced due to addition of Anti-oxidants and also due to degasification.

In case of equipment failure or spillage, vegetable oil decomposition is very slow. The above experimental results justified that, the antioxidants blended indigenous oil can be treated as alternate oil for transformer applications in power system and also it is environmental supportive by means of biodegradation. As the flash point of Indigenous oil is better compared to Mineral oil and results in high fire withstanding capacity. Further this work can be extended by considering Indigenous oil with different antioxidants. The other properties can also be investigated by reducing the moisture content by adopting nitrogen bubbling method and also by other method.

- D M Srinivasa and Usha Surendra “Comparative study of Breakdown Phenomena and Viscosity in Liquid Dielectrics” 2019 Innovations in Power and Advanced Computing Technologies (i-PACT), 2019 Vellore, India https://doi.org/: 10.1109/i-PACT44901.2019.8960134.

- Ankit Chouhan, Raj Kumar Jarial, and U. Mohan Rao “Thermal Performance of Nomex-910 and TUK Insulating Papers in Soya based Natural Ester Oil” International Journal on Electrical Engineering and Informatics, 12(1), March 2020. https://doi.org/: 10.15676/ijeei.2020.12.1.5.

- Muhammad Nazori Deraman, Norazhar Abu Bakar, Nur Hakimah Ab Aziz, Imran Sutan Chairul,Sharin Ab Ghani “The Experimental Study on the Potential of Waste Cooking Oil as a New Transformer Insulating Oil” Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 69(1), 74-84, 2020, https://doi.org/10.37934/arfmts.69.1.7484.

- C. Subalaksmi, M. Bakrutheen, M. Willjuice Iruthayarajan “Influence of Aging Derivatives on Properties of Natural Ester Oil” International Journal of Innovative Technology and Exploring Engineering (IJITEE), 9(4), February 2020, https://doi.org/: 10.35940/ijitee.D2031.029420.

- M. Rao, I. Fofana, T.Jaya, Esperanza Mariela Rodriguez-Celis, Jocelynalbert and Patrick Picher “Alternative Dielectric Fluids for Transformer Insulation System: Progress, Challenges, and Future Prospects” IEEE Access, 7, 2019, 10.1109/ACCESS.2019.2960020.

- S. Senthil Kumar, A. Arul Marcel Moshi, S.R.Sundara Bharathi, K.Karthik Kumar “Optimization of Various Natural Ester Oils Impregnated Nomex Paper Performance in Power Transformer Applications under Different Ageing Conditions”, International Journal of Recent Technology and Engineering (IJRTE), 8(3), September 2019, https://doi.org/: 10.35940/ijrte.C5832.098319.

- K. Sindhuja, M.Srinivasan, N.Niveditha “Natural Esters as an Alternative to Mineral oil in Transformer Applications”, International Journal of Pure and Applied Mathematics, 118(20), 723-732,2018, http://www.ijpam.eu.

- K. Jariyanurat, S. Maneerot, P. Nimsanong, P. Kitcharoen, P. Chaisiri, N. Pattanadech “Dielectric Properties of Mineral oil compared with Natural Ester”, 19th IEEE International Conference on Dielectric Liquids (ICDL), Manchester, United Kingdom, 25 – 29 June, 2017, https://doi.org/: 978-1-5090-4877-9/17.

- T. Mariprasath and V. Kirubakaran “Thermal degradation analysis of pongamia pinnata oil as alternative liquid dielectric for distribution transformer”, Indian Academy of Sciences, 41(9), 933–938 , September 2016, https://doi.org/: 10.1007/s12046-016-0529-0.

- M. H. A. Hamid, M. T. Ishak, M. F. Md. Din, N. S. Suhaimi, N. I. A. Katim, “Dielectric Properties of Natural Ester Oils Used for Transformer Application Under Temperature Variation”, IEEE 6th International Conference on Power and Energy (PECON 2016), 2016, Melaka, Malaysia, https://doi.org/: 10.1109/PECON.2016.7951472.

- N. A. Muhamad and S. H. M. Razali, Electrical and Chemical Properties of New Insulating Oil forTransformer Using PureCoconut Oil”, Journal of Advanced Research in Materials Science, 25(1). 1-9, 2016, ISSN (online): 2289-7992.

- Nur Aqilah Mohamad, Norhafiz Azis, Jasronita Jasni, Mohd Zainal Abidin Ab Kadir, Robiah Yunus, Mohd Taufiq Ishak and Zaini Yaakub, “Investigation on the Dielectric, Physical and Chemical Properties of

Palm Oil and Coconut Oil under Open Thermal Ageing Condition”, J Electr Eng Technol; 11(3): 690-698,2016, https://doi.org/: 10.5370/JEET.2016.11.3.690. - S. Banumathi, S.Chandrasekar “Analysis of Breakdown Strength and Physical Characteristics of Vegetable Oils for High Voltage Insulation Applications” Journal of Advances in Chemistry, 12(16), 4902-4912, 2016.

- S. Senthil Kumar, Dr. M. Willjuice Iruthayarajan, M. Bakrutheen “Analysis of Vegetable Liquid Insulating Medium for Applications in High Voltage Transformers”, In 2014 International Conference on Science Engineering and Management Research (ICSEMR), 1-5. IEEE, 2014.

- M.S. Ahmad Kamal,N. Bashir, N. A. Muhamad “Insulating Properties ofVegetableOilsandTheirBlends”, 2013 IEEE 7th International Power Engineering and Optimization Conference (PEOCO2013), Langkawi, Malaysia, 3-4 June, 2013. https://doi.org/: 978-1-4673-5074-7/13.

- U.D. Sankarasubbu and Senthil Kumar Suburaj Examining the Properties of Neem Oil, Sunflower Oil and Mahua Oil with Antioxidants and Nano Powders for Power Transformer” American Journal of Electrical and Computer Engineering, 3(1), pp. 20-29, 2019. doi: 10.11648/j.ajece.20190301.13