Development of Soil Moisture Monitoring by using IoT and UAV-SC for Smart Farming Application

Volume 5, Issue 4, Page No 381-387, 2020

Author’s Name: Sarun Duangsuwan1,a), Chakree Teekapakvisit1, Myo Myint Maw2

View Affiliations

1Information Engineering, Prince of Chumphon Campus, King Mongkut’s Institute of Technology Ladkrabang, Bangkok, 86160, Thailand

2Department of Computer Engineering and Information Technology (CEIT), Mandalay Technological University (MTU), Mandalay, 05011, Myanmar

a)Author to whom correspondence should be addressed. E-mail: sarun.du@kmitl.ac.th

Adv. Sci. Technol. Eng. Syst. J. 5(4), 381-387 (2020); ![]() DOI: 10.25046/aj050444

DOI: 10.25046/aj050444

Keywords: UAV-SC, IoT, Soil moisture monitoring, Mobile application, Smart farming

Export Citations

Soil moisture is a fundamental factor for smart farming that is used to control the water management system. In this paper, the unmanned aerial vehicle (UAV) small cell (UAV-SC) can provide Internet of things (IoT) as the hotspot mobility network, due to the minimum limitation energy of connected IoT. The development of ground sensor (GS) communicates to the UAV-SC called GS-UAV-SC model for soil moisture monitoring is proposed to smart farming. UAV-SC aims to fulfill the data collection task with a limitation of GSs power. In the experiment, the two case scenarios: Napier grass farm and Ruzi grass farm are implemented. The result of soil moisture status is demonstrated as an example of data in real time on a mobile application monitoring system. The proposed system is useful for users/farmers to know the soil moisture data quickly for smart farming applications.

Received: 19 June 2020, Accepted: 17 July 2020, Published Online: 28 July 2020

1. Introduction

Recently, agricultural UAV or drones become one of the most useful agricultural instruments utilized in smart farming, especially in the ground sensing applications. The UAV is employed as a mobility hotspot in the area lacking of the communication network to collect the data of soil and corps in order to monitor and control the water management system for precision agriculture. The agricultural UAV with a combination of IoT sensors are preferred. At present, the IoT sensors detect temperature and moisture of the soil and send them to farmers by using the UAV. Therefore, the identification of locations that suffer from droughts, water scarcity, and dryness of soil profile is easily observed. It helps the farmers to take precautionary methods such as contouring, damming, draining the surface water, and curtailing for further irrigation. Small UAV, either copters or flat-winged models with a combination of IoT sensors are essential.

In [1], the authors firstly introduced UAV which plays a great role in the aerial imagery of soils, particularly soil characteristics. Drones are attractive because they can fly at a low attitude over the fields, as many times as requires in the short intervals to study the same location. The result in [1] showed that the UAV or drones are one of the common methods for obtaining high-resolution maps showing spatial and temporal changes in soil moisture. However, the UAV imagery with low resolution is not used consistently to evaluate a field experiment. In [2], the authors have shown that the precision of soil moisture measurement with the frequency domain reflection (FDR) method was highly accurate. However, the soil moisture FDR sensor type is still expensive. Therefore, the low-cost capacitive sensor and very low-cost resistive sensors have been investigated in [3]. The authors have presented that low-cost capacitive sensors with soil-specific calibration matched the performance of the secondary standard and could possibly be used for water management with limited effects on irrigation efficiency. Nowadays, most of soil moisture application is based on IoT networking [4] or wireless sensor networking (WSN) [5]. The objective is to automatically obtain the agricultural parameters without requiring human-to-human or human-to-computer.

2. Related Work

2.1. UAV-SC

Most of the wireless IoT nodes utilized in the agricultural environment limit power energy which leads to the propagation problem in the surrounding area. Interestingly, B. Liu et al. [6] have proposed to solve the resource allocation problem in their UAV and IoT. The UAV works as power distribution by using a dynamic gamin-based model for wireless power transfer applications. The authors in [6] have illustrated that the power energy transfer of UAV depends on the amount of the density of IoT wireless nodes and they can be controlled by the power by using the dynamic game method. On the other hand, the proposed measurement aided dynamic planning algorithm in [7] can solve the problem-based of multiple IoT connectivity network. This algorithm can help to control the drone small cell (DSC) base station as a self-configuration on the fly regarding the cell being located and channel being used, based on the real-time measurement of network throughput. In addition, more increasingly, an optional mobile backhaul link might use the drone or UAV aided emergency network [8]. However, the problem-based such as the inter-cell interference should be considered. In [9], the multiple DSCs used for the several based stations were optimized by using the equivalent uniform density plane entity (EUDPE) method. The results indicated that the increase of the transmission power of drone did not necessarily improve coverage performance for the IoT connectivity. Similar to the drone base stations (DBSs) in [10], the authors proposed a realistic mathematical model for the joint optimization problem of DBS placement and IoT users. Path loss measurement for an air-to-ground channel was investigated in [10]. For the data monitoring system based on WSN with the large-scale area such as a coast or river [11], the authors considered to maximize data collection with given energy budgets for the drone and sensors. DroneTank [11], the UAV can determine the flight path and speed to conduct data collection. As mentioned in the works of literature, the UAV-SC for ground sensing is very important in the smart farming applications.

2.2. Smart Farming

Recently, the proposed AgriLogger has been implemented in Italy [12]. The aim is to build precision agriculture in the areas lacking data communication networks that can collect data and store the long periods and transmitted agrometeorological data, such as temperature and relative humidity. The drone is equipped with a payload, such as a wireless transceiver, radio transmitter, and GNSS receiver. Additionally, a communication link provides the narrowband IoT (NB-IoT) network to collect the data via cloud management. AgriLogger was able to collect and store for long periods estimated for more than ten years, and consistently, agrometeorological parameters data in a successful way would be great profit for agriculture. As well-known that the WSN technology is useful for precision agriculture as well as the IoT solution. There are several works focused on using WSN [13,14]. In [15], the authors have presented the technique and practice of precision agriculture. They implied that precision agriculture is to provide decision support systems based on multiple parameters impacted to the crops plantation such as soil moisture, water management, wind speed, and so on, by using WSN-based or IoT-based cloud computing. In [16], a secure IoT-based WSN framework for smart agriculture was described. The simulation results show that the proposed was more efficient compared to the IoT communication reliabilities. The network throughput was increased to 13.5 % and 38.5 % for the packets drop ratio, 13.5 % for the network latency, 16 % for the energy consumption, and 26 % for the routing overheard of smart agriculture.

SmartFarmNet [17] platform is an example application for smart agriculture in Australia by using IoT platform. It provides a scalable sensor data acquisition, analysis, and visualization platform for smart farming applications, based on IoT. Interestingly, this platform measures soil moisture at particular multiple depths and steams data from the physical sensors to monitor a phenomenon. By using the SmartFarmNet gateway to process soil moisture data which is close to the source, the cloud computing performs real-time analysis on incoming sensor data streams. For a platform of precision agriculture, SmartFarmNet is an existing model of smart agriculture based on IoT-based platform. Considering the IoT for smart farming, the IoT platform can help the farmer to predict the disease of the strawberry farm in [18]. However, the problem is the false detection probability of IoT sensors to the gateway. Then, the authors in [19] have presented a solution called SensorTalk to automatically detect the potential sensor failures and semi-automatically calibrate the aging sensors. The solution showed that the false detection probability of IoT sensors to the gateway was reduced to less than 0.7 %.

In related work of smart irrigation, IoT framework for smart irrigation such as data monitoring, preprocessing, fusion, synchronization, storage, and irrigation management enriched by the prediction of soil moisture was presented in [20]. Smart&Green was used to preprocess soil moisture data with outlier removal criteria and techniques of Zscore, MZscore, GESD, and Chauvenet to provide a more precise irrigation water needed in irrigation management. While the propose of IoT for the water management interestingly was presented in [21], WSN, LoRa, and ESP32 modules were used. The system retrieved real-time data and used them to determine the correct amount of water to be used in a garden. With this solution [21], it was possible to save up to 34 % of water with sensor data from temperature, humidity, and soil moisture, or up to 26 % with only temperature inputs. At present, the application of IoT in smart farming is rapidly emerging. A Long-range wide area network (LoRaWAN) based on IoT platform has introduced and called LoRaFarM [22]. The LoRaFarM platform has evaluated on a real farm in Italy. This system can collect data such as air, soil, temperature, and humidity. The advantage of the LoRa network is the long-range communication network and life-long battery of sensors, but it is still needed more gateways in the field. In [22], the design for the soil moisture sensor kit was proposed. The LoRaFarM hardware was designed by using the 1W solar-cell, solar charger, soil sensor, LoRa module at 868 MHz, and LiPo battery.

3. Proposed Model and Implementation

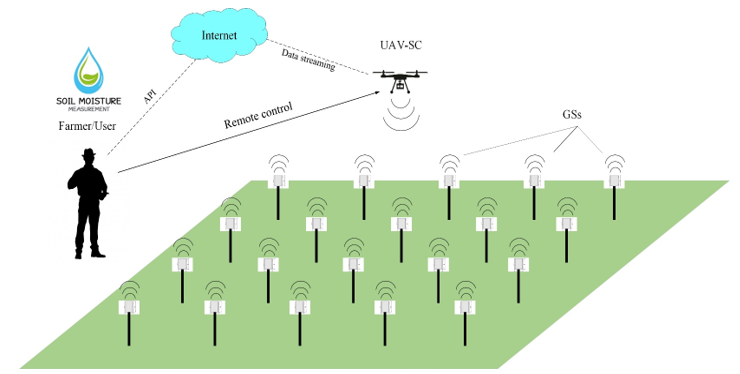

The GS-UAV-SC model for smart farming applications is shown in Figure 1. It can be noted that the IoT soil moisture GS kits were installed in the field, then, were connected to the UAV-SC to transfer data streaming to the internet. After that, the data are stored and computed on the cloud platform. Additionally, the farmer/user can control the UAV around the field in order to collect all data from every sensor. User can monitor the data via the application program interface (API) on the mobile application. This proposed model aims to compensate for the low energy from the multiple GSs connectivity.

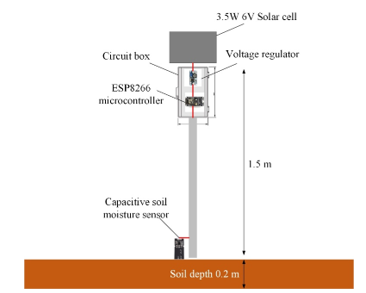

The structure model of the soil moisture GS prototype is shown in Figure 2. It can be noted that this platform would be used in case of sunlight. Herein, the capacitive soil moisture was used in this study. By using the capacitive soil moisture GS, the capacitance is varied based on the water content present in the soil. The capacitance converted into voltage level basic from 1.2 V to 3.0 V maximum. The advantage of capacitive soil moisture GS which is made of corrosion-resistant material is that it gives long service life. The structure model of the soil moisture GS prototype consists of five parts:

Figure 1: The GS-UAV-SC model in smart farming application.

Figure 1: The GS-UAV-SC model in smart farming application.

Figure 2: The structure model of soil moisture GS prototype.

Figure 2: The structure model of soil moisture GS prototype.

- Polycrystalline solar cell panel size is 165 mm wide and 135 mm length. The maximum voltage is 6 V, the maximum current is 583 mA, and the maximum output power is 3.5 W.

- Voltage regulator is DC to DC up/down LM2596 module, the maximum output current is 3 A, and the size is 50 mm wide and 37 mm

- Microcontroller ESP8266 NodeMCU is used for controlling data from the soil moisture and transmitting to WiFi internet. The voltage is driven at 3.3 V and current consumption ranges from 70 mA to 240 mA. The transmitting power of microcontroller is 20 dBm, and it supports 11 b/g/n.

- Capacitive soil moisture sensor SKU: SEN0193, this module includes an on-board voltage regulator which gives an operating voltage range of 1.2 V to 3.0 V. The operating current is 5 mA. This module is an analog sensor which has 3-pins: A0 signal pin, positive pin +, and negative pin -. The depth of soil moisture sensor in the soil is 0.2 m according to the standard as shown Figure 2.

- The material structure is made from aluminum pipe, and shield is inserted in the circuit box.

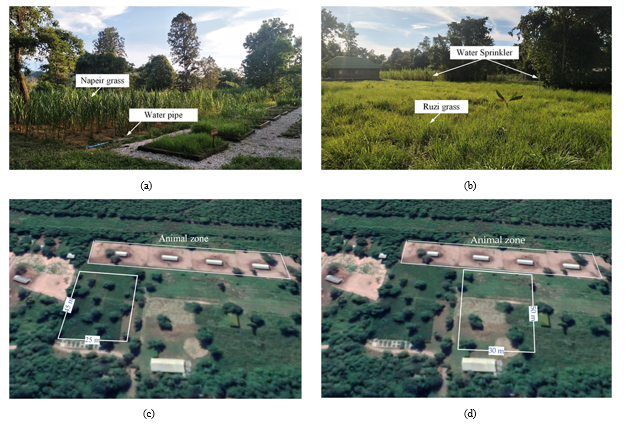

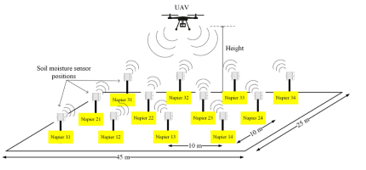

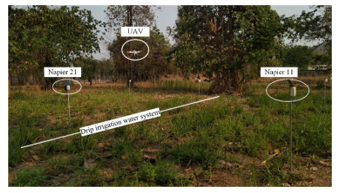

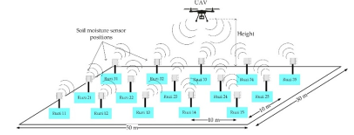

The implementation was conducted at the Tropical Animal Research Institute, Ramkhamhaeng University, Thailand. Figure 3(a) shows an example location of Napier grass farm and Ruzi grass farm in Figure 3(b) where the dimension of Napier grass farm is 25 m wide and 45 m length as shown in Figure 3(c) and Ruzi farm is 30 m wide and 50 m length in Figure 3(d). It is noted that these Napier and Ruzi grass are the main food of animals in the smart farm and 50 m of length in Figure 3(d). To note that, these Napier and Ruzi grass are mainly food of the animals within the smart farm.

3.1. Data Processing

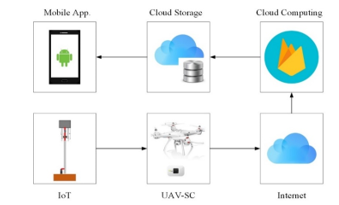

The block diagram of data processing is shown in Figure 4. The quadcopter UAV is used for mobility and mounted with the WiFi transceiver. The WiFi transceiver radiates power to the GSs and is connected with the microcontroller ESP8266 NodeMCU module. After receiving the data from the capacitive soil moisture sensor, the ESP8266 NodeMCU transmits data to the internet, cloud computing, and cloud storage based on the Google firebase solution. Eventually, the soil moisture data is alerted to the mobile application.

Figure 3: Smart farming of the Tropical Animal Research Institute, Ramkhamhaeng University: (a) Side view of Napier grass farm; (b) Side view of Ruzi grass farm; (c) Top view of Napier grass dimension; (d) Top view of Ruzi grass dimension.

Figure 3: Smart farming of the Tropical Animal Research Institute, Ramkhamhaeng University: (a) Side view of Napier grass farm; (b) Side view of Ruzi grass farm; (c) Top view of Napier grass dimension; (d) Top view of Ruzi grass dimension.

Figure 4: Block diagram of data processing.

Figure 4: Block diagram of data processing.

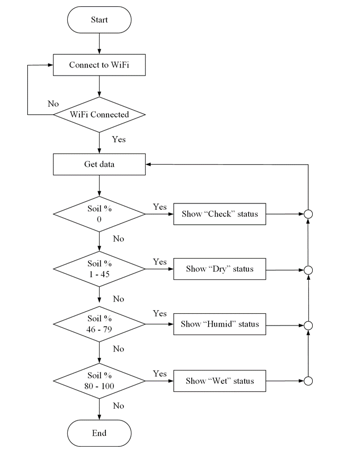

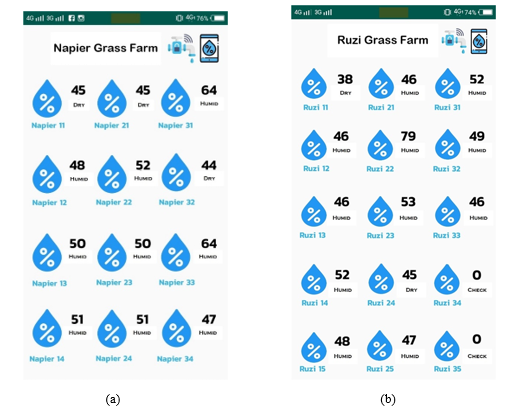

The flowchart of the soil moisture monitoring process is shown in Figure 5. Under the condition of soil moisture, the level of the moisture is set to be alerted on the mobile application as follows:

- With the show “check” status, all sensors send the data as 0 %. It means that the capacitive soil moisture sensor is disconnected..

- With the show “Dry” status, all sensors send the data as the range between 1 % to 45 %. It means that the soil is dry.

- With the show “Humid” status, all sensors send the data as the range from 46 % to 79 %. It means that the soil is humid.

- With the show “Wet” status, all sensors send the data as the range between 80 % and 100 % . It means that the soil is wet.

Figure 5: Flowchart of decision.

Figure 5: Flowchart of decision.

4. Experimental Setup

This section demonstrates the experimental setup in both Napier farm and Ruzi farm.

Figure 6: Experimental setup in Napier farm with 12 GSs.

Figure 6: Experimental setup in Napier farm with 12 GSs.

Figure 7: Real-time test in Napier farm.

Figure 7: Real-time test in Napier farm.

Figure 8: Experimental setup in Ruzi farm with 15 GSs.

Figure 8: Experimental setup in Ruzi farm with 15 GSs.

The experimental setup in Napier farm is demonstrated in Figure 6. The GSs are installed along the line of drip irrigation water systems in the field. The separation distance of each sensor is 10 m, and the position names are Napier11 to Napier34. Real-time test in Napier farm is shown in Figure 7. The flight time of the UAV is approximately 20 minutes, and the altitude is varied from 1 m to 10 m. For the sensor depth, it is a pin into the soil with about 0.2 m depth. The tested soil moisture GS kits are performed by the power supply from the solar cell panel in the day time. Therefore, the farmer/user can monitor the data in real time..

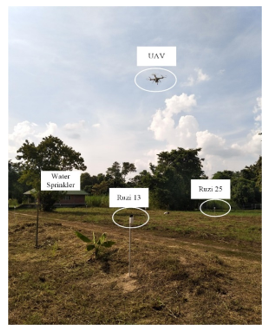

Additionally, the experimental setup in Ruzi farm is shown in Figure 8 and real-time test in Figure 9. It demonstrates the position of sensors in the field in which the number of GS is 15 positions. The GS sets as Ruzi11 to Ruzi35. The sensors installed along the line of the water sprinkler in the field. At the experiment, the UAV altitude was also varied from 1 m to 10 m. Note that the average temperature of all days of these locations was 40 degrees. As a result, both the Napier and Ruzi farms need more water spraying every day. Therefore, the GS-UAV-SC model is useful for the farmer/user to automatically control the on-off of the water management system in these agricultural farms.

Figure 9: Real-time test in Ruzi farm.

Figure 9: Real-time test in Ruzi farm.

5. Results and Discussion

The experimental data tests were performed in the daytime on April 2, 2020, and during 2 PM to 5:15 PM. Table 1 and Table 2 show the real-time soil moisture values before and after the opening of the drip irrigation water system in Napier farm, monitoring it as a percentage. Meanwhile, the real-time soil moisture monitoring in Ruzi farm is presented in Table 3 and Table 4, respectively. Herein, the WiFi network is connected by the UAV-SC in every fifteen minutes.

Table 1: In case: Before opening the water system in Napier farm.

| Positions | Soil moisture monitoring (%) | |||||

| Time | 2.00PM | 2.15PM | 2.30PM | 2.45PM | 3.00PM | 3.15PM |

| Napier 11 | 23 | 23 | 24 | 25 | 25 | 25 |

| Napier 12 | 32 | 32 | 34 | 33 | 34 | 34 |

| Napier 13 | 37 | 37 | 38 | 38 | 38 | 39 |

| Napier 14 | 43 | 43 | 44 | 45 | 45 | 43 |

| Napier 21 | 40 | 41 | 42 | 41 | 41 | 42 |

| Napier 22 | 22 | 23 | 25 | 24 | 23 | 25 |

| Napier 23 | 28 | 30 | 29 | 30 | 28 | 28 |

| Napier 24 | 42 | 41 | 41 | 40 | 42 | 42 |

| Napier 31 | 32 | 31 | 31 | 31 | 32 | 32 |

| Napier 32 | 32 | 33 | 34 | 33 | 33 | 34 |

| Napier 33 | 30 | 30 | 32 | 32 | 31 | 30 |

| Napier 34 | 26 | 26 | 28 | 28 | 27 | 28 |

Table 2: In case: After opening the water system in Napier farm.

| Positions | Soil moisture monitoring (%) | |||||

| Time | 4.00PM | 4.15PM | 4.30PM | 4.45PM | 5.00PM | 5.15PM |

| Napier 11 | 45 | 47 | 52 | 56 | 61 | 59 |

| Napier 12 | 48 | 49 | 55 | 60 | 62 | 61 |

| Napier 13 | 50 | 53 | 57 | 61 | 64 | 63 |

| Napier 14 | 51 | 55 | 61 | 64 | 66 | 65 |

| Napier 21 | 45 | 47 | 54 | 55 | 64 | 64 |

| Napier 22 | 52 | 53 | 56 | 60 | 63 | 63 |

| Napier 23 | 50 | 52 | 55 | 61 | 62 | 61 |

| Napier 24 | 51 | 53 | 58 | 64 | 65 | 62 |

| Napier 31 | 64 | 66 | 67 | 67 | 68 | 65 |

| Napier 32 | 44 | 45 | 55 | 58 | 59 | 56 |

| Napier 33 | 64 | 65 | 67 | 69 | 69 | 67 |

| Napier 34 | 47 | 47 | 48 | 50 | 51 | 49 |

Table 3: In case: Before opening the water system in Ruzi farm.

| Positions | Soil moisture monitoring (%) | |||||

| Time | 2.00PM | 2.15PM | 2.30PM | 2.45PM | 3.00PM | 3.15PM |

| Ruzi 11 | 21 | 20 | 20 | 18 | 19 | 20 |

| Ruzi 12 | 21 | 20 | 19 | 20 | 19 | 21 |

| Ruzi 13 | 25 | 25 | 26 | 27 | 26 | 25 |

| Ruzi 14 | 31 | 30 | 30 | 31 | 30 | 31 |

| Ruzi 15 | 32 | 32 | 33 | 34 | 33 | 34 |

| Ruzi 21 | 16 | 16 | 15 | 16 | 16 | 18 |

| Ruzi 22 | 13 | 14 | 15 | 16 | 17 | 17 |

| Ruzi 23 | 25 | 26 | 26 | 27 | 28 | 28 |

| Ruzi 24 | 31 | 30 | 31 | 30 | 30 | 31 |

| Ruzi 25 | 33 | 34 | 33 | 34 | 34 | 33 |

| Ruzi 31 | 12 | 13 | 14 | 14 | 15 | 16 |

| Ruzi 32 | 15 | 14 | 15 | 18 | 17 | 18 |

| Ruzi 33 | 22 | 23 | 22 | 23 | 23 | 25 |

| Ruzi 34 | 0 | 0 | 0 | 0 | 0 | 0 |

| Ruzi 35 | 0 | 0 | 0 | 0 | 0 | 0 |

Table 4: In case: After opening the water system in Ruzi farm.

| Positions | Soil moisture monitoring (%) | |||||

| Time | 4.00PM | 4.15PM | 4.30PM | 4.45PM | 5.00PM | 5.15PM |

| Ruzi 11 | 38 | 46 | 47 | 48 | 48 | 47 |

| Ruzi 12 | 46 | 48 | 51 | 53 | 52 | 51 |

| Ruzi 13 | 46 | 48 | 53 | 56 | 54 | 54 |

| Ruzi 14 | 52 | 53 | 55 | 57 | 56 | 55 |

| Ruzi 15 | 48 | 49 | 54 | 57 | 58 | 56 |

| Ruzi 21 | 46 | 48 | 51 | 52 | 53 | 54 |

| Ruzi 22 | 79 | 80 | 81 | 79 | 74 | 71 |

| Ruzi 23 | 53 | 54 | 59 | 60 | 62 | 59 |

| Ruzi 24 | 45 | 46 | 52 | 54 | 55 | 53 |

| Ruzi 25 | 47 | 49 | 54 | 54 | 54 | 53 |

| Ruzi 31 | 52 | 54 | 60 | 61 | 59 | 57 |

| Ruzi 32 | 49 | 51 | 55 | 55 | 56 | 54 |

| Ruzi 33 | 46 | 48 | 51 | 52 | 53 | 51 |

| Ruzi 34 | 0 | 0 | 0 | 0 | 0 | 0 |

| Ruzi 35 | 0 | 0 | 0 | 0 | 0 | 0 |

Before the opening of the drip irrigation water system in Napier grass farm, soil moisture sensors were tested from 2 PM to 3:15 PM. The results of soil moisture sensors show that the data is in the range from 22 % to 42 % of the real-time monitoring. Therefore, the status was Dry status. After the opening of the drip irrigation water system for about forty-five minutes, it is observed that the soil moisture values were rapidly increased in the range of 45 % to 69 % as shown in Table 2. Thus, the “Humid” status was shown on the mobile application.

In Ruzi farm, the soil moisture values in Ruzi farm were in the range from 12 % to 34 % in Table 3 before opening the water sprinkler system, Therefore, the status showed as Dry. After the opening water sprinkler system about forty-five minutes in Ruzi farm, the results of soil moisture values were in the range from 38 % to 81 %. As a result, the status shown on mobile application was Dry, Humid, Wet, and Check status. And then, the capacitive soil moisture sensors were removed from the soil. Both Ruzi 34 and Ruzi 35 were 0 % with the “Check” status. The experiment data in Ruzi farm were collected on April 3, 2020.

The examples of mobile application on screen as real-time monitoring were shown in Figure 10 (a)-(b). The data collected at 4 PM is shown in Table 2 and Table 4. Figure 10 (a) and 10 (b) show the status of soil moisture values in Napier farm and Ruzi farm. The application is easily used and can be applied to control the water management (on-off) system both in Napier and Ruzi farms. It took just to 15 minutes to collect the data for the proposed model.

Figure 10: Example of real-time monitoring on mobile application at 4 PM:

Figure 10: Example of real-time monitoring on mobile application at 4 PM:

(a) On the screen in Napier farm. (b) On the screen in Ruzi farm.

6. Conclusion

In this paper, the proposed GS-UAV-SC model based on IoT and wireless communication connected network in smart farming has been implemented for soil moisture monitoring. The low-cost multiple GSs were designed as the ground sensing to monitor the soil moisture in the daylight both for Napier grass farm and Ruzi grass farm. The UAV-SC is equipped with the WiFi transceiver similar to the hotspot mobility and connected with the multiple GSs. This proposed smart farming system is called the GS-to-UAV-SC communication system. The implementation and results confirm that the UAV-SC can be applied as mobility transceiver to compensate for the low energy of GSs, including the real-time data that are designed to monitor soil moisture values on the mobile application. In future work, the optimization of path loss model for smart farming (SF) system will be implemented by the machine learning algorithms. .

Conflict of Interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Acknowledgment

This research was financially supported by the Academic Melting Pot, KMITL research fund. The authors would like to thank the Tropical Animal Research Institute, Ramkhamhaeng University, in Thailand, which was cooperative research in this work.

- C. M. Gevaert, J. Suomalainen, J. Tang, L. Kooistra, “Generation of Spectral-Temporal Response Surfaces by Combining Multispectral Satellite and Hyperspectral UAV Imaginary for Precision Agricultural Applications” IEEE J. of Selected Topics in Applied Earth Observations and Remote Sensing, 8(6), 3140–3146, 2015. https://doi.org/10.1109/JSTARS.2015.2406339

- L. Chen, L. Zhangzhong, W. Zheng, J. Yu, Z. Wang, L. Wang, C. Huang “Data-Driven Calibration of Soil Moisture Sensor Considering Impacts of Temperature: A Case Study on FDR Sensors” Sensors, 19(20), 1–11, 2019. https://doi.org/10.3390/s19204381

- S. Adla, N. K. Rai, S. H. Karumanchi, S. Tripathi, M. Disse, S. Pande “Laboratory calibration and performance evaluation of low-cost capacitive and very low-cost resistive soil moisture sensors” Sensors, 20(2), 1–27, 2020. https://doi.org/10.3390/s20020363

- W. L. Chen, Y. B. Lin, Y. W. Lin, R. Chen, J. K. Liao, F. L. Ng, Y. Y. C. Liu, C. C. Wang, C. H. Chiu, T. H. Yen, “AgriTalk: IoT for Precision Soil Farming of Turmeric Cultivation” IEEE Internet of Things J., 6(3), 5209–5223, 2019. https://doi.org/10.1109/JIOT.2019.2899128

- F. Viani, M. Bertolli, A. Polo, “Low-Cost Wireless System for Agrochemical Dosage Reduction in Precision Farming” IEEE Sensors J., 17(1), 5–6, 2017. https://doi.org/10.1109/JSEN.2016.2622244

- B. Liu, H. Xu, X. Zhou, “Resource Allocation in Unmanned Aerial Vehicles (UAV)-Assisted Wireless-Powered Internet of Things” Sensors, 19(8), 1–13, 2019. https://doi.org/10.3390/s19081908

- N. Lu, Y. Zhon, C. Shi, N. Cheng, B. Li, “Planning While Flying: A Measurement-Aided Dynamic Planning of Drone Small Cells” IEEE Internet of Things J., 6(2), 2693–2705, 2019. https://doi.org/ 10.1109/JIOT.2018.2873772

- G. Castellanos, M. Deruyck, L. Martens, W. Joseph, “Performance Evaluation of Direct-Link Backhaul for UAV-Aided Emergency Networks” Sensors, 19(15), 1–16, 2019. https://doi.org/10.3390/s19153342

- C. Dong, J. Xie, H. Dai, Q. Wu, Z. Qin, Z. Feng “Optimal Deployment Density for Maximum Coverage of Drone Small Cells” China Communications, 15(5), 25–40, 2018. https://doi.org/10.1109/CC.2018.8387984

- A. Ahmed, M. Awais, T. Akram, S. Kulac, M. Alhussein, K. Aurangzeb, “Joint Placement and Device Association of UAV Base Stations in IoT Networks” Sensors, 8(6), 1–16, 2019. https://doi.org/10.3390/s19092157

- R. Xoing, F. Shan, “DroneTank: Planning UAVs Flight and Sensors Data Transmission under Energy Constraints” Sensors, 18(9), 1–19, 2018. https://doi.org/10.3390/s18092913

- M. Idbella, M. Iadaresta, G. Gagliarde, A. Mennella, S. Mazzoleni, G. Bonanomi, “AgriLogger: A New Wireless Sensor for Monitoring Agrometeorological Data in Areas Lacking Communication Networks” Sensors, 20(6), 1–13, 2020. https://doi.org/10.3390/s20061589

- M. Bacco, A. Berton, A. Gotta, L. Caviglione, “IEEE 802.15.4 Air-Ground UAV Communications in Smart Farming Scenarios” IEEE Communication L. 22(9), 1910–1913, 2018. https://doi.org/10.1109/LCOMM.2018.2855211

- F. Viani, M. Bertolli, A. Polo, “Low-Cost Wireless System for Agrochemical Dosage Reduction in Precision Farming” IEEE Sensors J., 17(1), 5–6, 2017. https://doi.org/10.1109/JSEN.2016.2622244

- U. Shafi, R. Mumtaz, J. Garcia-Nieto, S. A. Hassan, S. A. Raza Zaidi, N. Iqbal, “Precision Agriculture Techniques and Practices: From Consideration to Applications” Sensors, 19(17), 1–25, 2019. https://doi.org/10.3390/s19173796

- K. Haseeb, I. U. Din, A. Almogren, N. Islam, “An Energy Efficient and Secure IoT-based WSN Framework: An Application to Smart Agriculture” Sensors, 20(7), 1–14, 2020. https://doi.org/10.3390/s20072081

- P. P. Jayaraman, A. Yavari, D. Geogakopoulos, A. Morshed, A. Zaslavsky, “Internet of Things Platform for Smart Farming: Experiences and Lessons Learnt” Sensors, 16(11), 1–17, 2016. https://doi.org/10.3390/s16111884

- S. Kim, M. Lee, C. Shin, “IoT-based Strawberry Disease Prediction System for Smart Farming” Sensors, 18(11), 1–17, 2018. https://doi.org/ 10.3390/s18114051

- Y. B. Lin, Y. W. Lin, J. Y. Lin, H. N. Hung, “SensorTalk: An IoT Device Failure Detection and Calibration Mechanism for Smart Farming” Sensors, 19(21), 1–19, 2019. https://doi.org/10.3390/s19214788

- N. G. S. Campos, A. R. Rocha, R. Gondim, T. L. Coelho da Sliva, D. G. Gomes, “Smart & Green: An Internet-of-Things Framework for Smart Irrigation” Sensors, 20(1), 1–25, 2020. https://doi.org/10.3390/s20010190

- A. Gloria, C. Dionisio, G. Simoes, J. Cardoso, P. Sebastiao, “Water Management for Sustainable Irrigation Systems using Internet-of-Things” Sensors, 20(5), 1–14, 2020. https://doi.org/10.3390/s20051402

- G. Codelippi, A. Cilfone, L. Davoli, G. Ferrari, “LoRaFarM: a LoRaWAN-based Smart Farming Modular IoT Agriculture” Sensors, 20(7), 1–24, 2020. https://doi.org/10.3390/s20072028