Acoustic Signal Processing and Noise Characterization Theory via Energy Conversion in a PV Solar Wall Device with Ventilation through a Room

Volume 3, Issue 4, Page No 130-172, 2018

Author’s Name: Himanshu Dehraa)

View Affiliations

Egis India Consulting Engineers Pvt. Ltd., Egis Tower, Plot # 66, Sector 32, Gurugram (Haryana), 122001, India

a)Author to whom correspondence should be addressed. E-mail: anshu_dehra@hotmail.com

Adv. Sci. Technol. Eng. Syst. J. 3(4), 130-172 (2018); ![]() DOI: 10.25046/aj030414

DOI: 10.25046/aj030414

Keywords: Acoustics, Signal Processing, Noise Characterization, Energy Conversion, Ventilation, Loudspeaker, PV Solar Wall Device

Export Citations

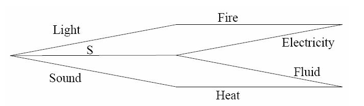

Noise defined as ‘a sensation of unwanted intensity of a wave’, is perception of a pollutant and a type of environmental stressor. The unwanted intensity of a wave is a propagation of noise due to transmission of waves (viz. physical agents) such as light, sound, heat, electricity, fluid and fire. The characterization of noise interference, due to power difference of two intensities in a wave is presented. Noise interference characterization in a wave is obtained depending on type of wave. Standard definitions of noise sources, their measurement equations, their units and their origins under limiting reference conditions are derived. All types of wave form one positive power cycle and one negative power cycle. The positive and negative noise scales and their units are devised depending on speed of noise interference in a wave. A numerical and experimental study was conducted for supporting the noise characterization theory via ascertainment of energy conversion characteristics of a pair of photovoltaic (PV) modules integrated with solar wall of an outdoor test-room. A pre-fabricated outdoor room was setup for conducting outdoor experiments on a PV solar wall with ventilation through the outdoor room. Acoustic signal processing is supported with some experimental and numerical results of a parallel plate PV solar wall device installed in an outdoor test-room to authenticate the noise interference equations. Detailed discussions on noise characterization theory along with some examples of noise filter systems as per noise sources are also presented. The noise characterization theory is also exemplified with some noise unit calculations using presented noise measurement equations.

Received: 04 June 2018, Accepted: 24 July 2018, Published Online: 29 July 2018

1. Introduction

The aim of this paper is to present acoustic signal processing and noise characterization theory with support of energy conversion models and experiments on a photovoltaic (PV) solar wall with ventilation through a room. This paper is an extension of work originally presented in conference [1, 2].

Noise, defined as ‘a sensation of unwanted intensity of a wave’, is perception of a pollutant and a type of environmental stressor. An environmental stressor such as noise may have detrimental effects on various aspects of health. The unwanted intensity of a wave is a propagation of noise due to transmission of waves (viz. physical agents) such as light, sound, heat, electricity, fluid and fire [1]. A unified theory for stresses and oscillations is applicable so as to take into effect of all the physical agents as an environmental stressor on a human body [3]. As per the theory, the stresses acted on a particle due to interaction of many forces are distinguished as fundamental, internal and external stresses. The existence of fundamental stresses is due to presence of electromagnetic and gravitational forces. The internal stresses are acted under the influence of fundamental stresses and are constituted by composition and properties of a particle. The external stresses are acted under the existence of an external source of energy.

Solar energy conversion occurs at solar cells and solar intensity of incident solar energy is converted into electric power and waste heat. The photovoltaic devices with ventilation provide means for converting waste heat lost to surrounding environment into useful thermal power [2-7]. The composite waves are transmitted in photovoltaic (PV) devices due to stresses and oscillations of incident solar and ventilation energy. In this way solar power intensity is converted into heat, fluid, electricity, light, sound and fire depending on intensities of its transmitted composite waves in a PV solar wall device.

1.1. Methodology

This paper has summarized the concept of acoustic signal processing and noise characterization theory with aid of energy conversion in a PV solar wall device. Basic definitions on noise characterization are presented in Appendix. Sources of noise are characterized as per physiological responses from human senses. Definitions of various types of noise as per type and speed of wave are presented. Noise measurement equations are deduced from the wave theory. Acoustic or noise filters as per source of various power systems are defined and illustrated with examples. Experimental results on energy conversion are presented on a PV solar wall device. Sensible heat storage capacity and thermal storage capacities are explained for their energy conversion phenomenon.

Some numerical results are also presented to support the noise characterization. In order to further authenticate the noise wave characterization, signal processing is achieved from a PV device composed of RC analogue signal. Acoustic signal processing is supported with some experimental and numerical results of a parallel plate PV solar wall device installed in an outdoor test-room for verification of the noise interference equations. Some noise unit calculations deduced from the numerical model based on newly devised noise measurement equations are also presented in tables. Detailed discussions are also presented on significance of noise characterization theory for: i) cities; ii) acoustics; iii) electrical engineering, instrumentation & control; iv) energy conversion in engines; v) noise pollution and control; vi) fire alarm systems; vii) operation of power systems; viii) friction & oscillations; ix) noise instrumentation; x) automatic control & management in noise systems; xi) potential research themes and graduate teaching subjects.

The following sections define and describe ‘noise’, its sources, its measurement equations with support of experimental and numerical results of a PV solar wall device with ventilation through a room. Discussions of noise characterization theory on solar energy acoustics, energy conversion model and experiments, acoustic signal processing, noise filters & their examples with description of sensors & transducers for a human brain along with human comfort & health are presented in later sections.

2. Noise Characterization

2.1. Source & Sink of Noise

The strength of a source is defined as total energy flow per unit time and unit length of line. A line which is drawn hypothetically perpendicular to the plane, from which energy is assumed to flow uniformly in all directions at normal angles to it, is defined as a source. It acts as a point in the usual two-dimensional energy flow diagram. The flow is in imaginary radial lines from the source, the current of energy flow is at a distance r from the source. The current is determined by the strength divided by the energy flow area [8-10].

2.2. Psychoacoustics in New Dimensions

The standard sources of noise along with their definitions, their measurement equations and measurement units are presented. A contemporary theory of psychoacoustics was presented for characterization of interference of noise waves due to difference of power of two intensities [11]. The difference of two intensities of power is due to transmission of heat, fluid, light, electricity, fire and sound into a particle body. The sources of noise are classified according to the type of wave of interference. The various types of noise are defined with factors of speed of wave, areas of energy stored in a wave, due to interference and difference of power between two intensities of wave. Noise filters as per source of noise signals from noise power systems are differentiated for filtering unwanted frequencies from solar power, electric power, light power, sound power, heat power, fluid power and fire power.

The interference of noise arises due to difference of power of two intensities [1-13]. The intensity of power for any particle body is a function of development of various stresses. The phenomenon of acoustic resonance arises due to matching of critical stress level with the natural stress level necessary for oscillation of a particle body. The criteria for generation of acoustic resonance include waves propagated with transmission of light, sound, noise, heat, electricity, fluid and fire from a particle body. The psychological feeling of sensation and perception of noise from light, sound, heat, electricity, fluid and fire is a physiological response from the sensory organs of a standard (average) human body.

3. Sources of Noise

The sources of noise are classified according to the type of wave of interference:

Light: In the electromagnetic radiation wavelength band from approximately between 380-765 nm, the visual sensation of light is tested by the eye of an observer with seeing of a radiant energy. The physiological response from an average eye defines units of light. The sensitivity of human eye is not same in all wavelengths or colors. The contribution of adding daylight is visual sensation in the visible region of the solar energy spectrum.

Sound: In the range of frequencies between 20 Hz and 20,000 Hz, the sound is evaluated due to presence of fluid pressure energy as a hearing sensation by the ear. The sound units are based on the functional feedback of an average ear. The sensitivity of sound to the whole frequency band is not same for human ear.

Heat: In the electromagnetic radiation between 0.1 μm to 100 μm, the heat as a temperature sensation is examined by the human body. The sensation function of temperature defines units of heat. The temperature sensation function is a measure of coldness and hotness. The comfort zone of temperature is evaluated from functional feedback of a human body which also defines thermal comfort. The contribution to discomfort of human body is in the ultra violet region of solar energy spectrum.

Electricity: With passing of direct current or an alternating current, the electricity as a shock sensation is evaluated by skin of an observer due to electromagnetic energy stored in a conductor which is short-circuited by a human body.

Fluid: The fluid as combined ventilation and breathing sensation is evaluated by amount of fluid passed either externally or internally through a standard (average) human body.

Fire: The exposure of radiant energy and fluid acting on skin surface of an average human body, defines the fire as a sensation of burning.

4. Noise Measurement Equations

The following standard measurement equations are derived and adopted from the standard definitions for sources of noise interference as mentioned in Appendix.

Noise of Sol: For a pack of solar energy wave, the multiplication of solar power storage and the velocity of light gives solar power intensity I. On taking logarithm of two intensities of solar power, I1 and I2, provides intensity difference. It is mathematically expressed as:

![]() Whereas logarithmic unit ratio for noise of sol is expressed as Sol. The oncisol (oS) is more convenient for solar power systems. The mathematical expression by the following equality gives an oncisol (oS), which is 1/11th unit of a Sol:

Whereas logarithmic unit ratio for noise of sol is expressed as Sol. The oncisol (oS) is more convenient for solar power systems. The mathematical expression by the following equality gives an oncisol (oS), which is 1/11th unit of a Sol:

![]() Noise of Therm: For a pack of heat energy wave, the multiplication of total power storage and the velocity of light gives heat power intensity I. The pack of solar energy wave and heat energy wave (for same intensity I), have same energy areas, therefore their units of noise are same as Sol.

Noise of Therm: For a pack of heat energy wave, the multiplication of total power storage and the velocity of light gives heat power intensity I. The pack of solar energy wave and heat energy wave (for same intensity I), have same energy areas, therefore their units of noise are same as Sol.

Noise of Photons: For a pack of light energy beam, the multiplication of total power storage and the velocity of light gives light power intensity I. The pack of solar energy wave and light energy beam (for same intensity I), have same energy areas, therefore their units of noise are same as Sol.

Noise of Electrons: For a pack of electricity wave, the multiplication of total electrical storage and the velocity of light gives electrical power intensity I. The pack of solar energy wave and electricity wave (for same intensity I), have same energy areas, therefore their units of noise are same as Sol.

Noise of Scattering: For a pack of fluid energy wave, the multiplication of total power storage and the velocity of fluid gives fluid power intensity I. On taking logarithm of two intensities of fluid power, I1 and I2, provides intensity difference. It is mathematically expressed as:

![]() Whereas, logarithmic unit ratio for noise of scattering is Sip. The oncisip (oS) is more convenient for fluid power systems.

Whereas, logarithmic unit ratio for noise of scattering is Sip. The oncisip (oS) is more convenient for fluid power systems.

The mathematical expression by the following equality gives an oncisip (oS), which is 1/11th unit of a Sip:

![]() For energy area determination of a fluid wave, the water with a specific gravity of 1.0 is the standard fluid considered with power of ±1 Wm-2 for reference intensity I2.

For energy area determination of a fluid wave, the water with a specific gravity of 1.0 is the standard fluid considered with power of ±1 Wm-2 for reference intensity I2.

Noise of Scattering and Lightning: For a pack of fire wave, the intensity I, of fire flash with power of light, is the multiplication of total power storage and the velocity of light. Whereas for a pack of fire wave, the intensity, I, of fire flash with power of fluid, is the multiplication of total power storage capacity and velocity of fluid.

- For a noise due to fire flash, the collective effect of scattering and lightning is to be obtained by superimposition principle.

- For same intensity I, the pack of solar energy wave and a fire flash with light power have same energy areas, therefore their units of noise are same as Sol. The therm power may also be included in fire flash with power of light.

- For same intensity I, the pack of fluid energy wave and a fire flash with fluid power have same energy areas, therefore their units of noise are same as Sip. In determining the areas of energy for the case of fluids other than water, a multiplication factor in specific gravity of fluid is to be considered.

Noise of Elasticity: For a pack of sound energy wave, the product of total power storage and the velocity of sound gives sound power intensity I. On taking logarithm of two intensities of sound power, I1 and I2, provides intensity difference. It is mathematically expressed as:

![]() Whereas, logarithmic unit ratio for noise of elasticity is Bel. The oncibel (oB) is more convenient for sound power systems. The mathematical expression by the following equality gives an oncibel (oB), which is 1/11th unit of a Bel:

Whereas, logarithmic unit ratio for noise of elasticity is Bel. The oncibel (oB) is more convenient for sound power systems. The mathematical expression by the following equality gives an oncibel (oB), which is 1/11th unit of a Bel:

4.1. Limiting Conditions

4.1. Limiting Conditions

The Table 1 summarises units of noise and their limiting conditions.

Table 1: Noise under Limiting Conditions

|

Referencea (I2 = ±1 Wm-2) |

Noise Scales and limiting Conditions | ||

| Noise of Sol | Noise of Scattering | Noise of Elasticity | |

| Units | Sol | Sip | Bel |

| I1 = 1 Wm-2 | No Positive Solar Energy | No Positive Fluid Energy | No Positive Sound Energy |

| I1 = 1+→0 Wm-2 | Decreasing Solar Energy | Decreasing Fluid Energy | Decreasing Sound Energy |

| I1= + ve | Increasing Solar Energy | Increasing Fluid Energy | Increasing Sound Energy |

| I1 = -1 Wm-2 | Negative Solar Energy | Negative Fluid Energy | Negative Sound Energy |

| Darkness | Low Pressure | Inaudible range | |

| I1 = -ve | Darkness increasing, distance from point source of light increasing | Low pressure increasing, vacuum approaching | Inaudible range increasing, vacuum approaching |

| I1 = -1+→0 Wm-2 | Negative Solar Energy | Negative Fluid Energy | Negative Sound Energy |

| Decreasing Darkness | Decreasing Low Pressure | Decreasing inaudible range | |

| * Reference value of I2 = ±1 Wm-2 signifies the limiting condition with areas of noise interference approaching to zero. | |||

There are following elaborative points on choosing an onci as 1/11th unit of noise [1]:

- Reference value used for I2 is -1 W m-2 on positive scale of noise and 1 W m-2 on negative scale of noise. In a power cycle, all types of wave form one positive power cycle and one negative power cycle (see Figure 10). Positive scale of noise has 10 positive units and one negative unit. Whereas, negative scale of noise has 1 positive unit and 10 negative units;

- Each unit of sol, sip and bel is divided into 11 parts, 1 part is 1/11th unit of noise;

- The base of logarithm used in noise measurement equations is 11;

- Reference value of I2 is -1 W m-2 with I1 on positive scale of noise, should be taken with negative noise measurement expression (see Eqs 2, 4 and 6), therefore it gives positive values of noise;

- Reference value of I2 is 1 W m-2 with I1 on negative scale of noise, should be taken with positive noise measurement expression (see Eqs 2, 4 and 6), therefore it gives negative values of noise.

5. Noise Filters

The noise filters are classified as per source signal of unwanted frequencies from solar power, electric power, light power, sound power, heat power, fluid power and fire power. An acoustic filter is an electrical analog circuit of various combinations of RC feedback circuit with an operational amplifier and is used to filter unwanted frequencies of oscillations from a power system [14]. It is a network with selective transmission for currents from a power system of varying frequency. The unwanted frequencies generated from a power system are removed by using an operational amplifier with different combination of filter arrangements. An operational amplifier is an integrated circuit that consists of several bipolar transistors, resistors, diodes, and capacitors, interconnected so that amplification can be achieved over a wide range of frequencies [15].

The action of filtering the frequency from a power system is based on the variation in the reactance of an inductance or a capacitance with change in frequency. The band of frequencies that can be removed from a power system can be at the low frequency end of frequency spectrum, at the high frequency end, at both ends, or in the middle of the spectrum. The filters to perform each of these operations are known respectively as low-pass filters, high-pass filters, band-pass filters and band-stop filters. There are many configurations of design of filters. The filters are divided into passive and active configurations. The passive filters are less effective simple circuits constructed with resistors, capacitors, and inductors. The active filters are useful in providing an effective filtering action than passive filters. The active filters require a source of operating power.

5.1. Noise Filter Systems

The criteria for definitions of filters for noise filtering is based on areas of energy stored in a wave due to noise interference, speed of wave and difference of power between two intensities of wave. The filtered noise signals are considered from systems of solar power, electric power, light power, sound power, heat power, fluid power and fire power. The noise filters as per sources of noise are defined as follows:

Filter for noise of sol: This filter is used to filter noise due to difference of power intensities between two solar power systems. Example: window curtain, window blind, wall and glass.

Filter for noise of therm: This filter is used to filter noise due to difference of power intensities between two heat power systems. Example: house, insulation, clothing and furnace.

Filter for noise of photons: This filter is used to filter noise due to difference of power intensities between two light power systems. Example: 3-D vision of any object, electric bulb, television, computer and LCD screen laptop.

Filter for noise of electrons: This filter is used to filter noise due to difference of power intensities between two electrical power systems. Example: AM/FM radio clock with ear phones, telephone instrument with ear phones and CD audio player with ear phones.

Filter for noise of scattering: This filter is used to filter noise due to difference of power intensities between two fluid power systems. Example: electric fan, pump, motor vehicle, river stream and tap water.

Filter for noise of scattering and lightning: This filter is used to filter noise due to difference of power intensities between two fire power systems. Example: lighter, matchstick, gas stove, locomotive engine and thunder-bolt.

Filter for noise of elasticity: This filter is used to filter noise due to difference of power intensities between two sound power systems. Example: your vocal apparatus, organ pipe, thunder-bolt and drum beats.

6. Some Examples of Noise Filters

Some examples of noise filters are enumerated as under.

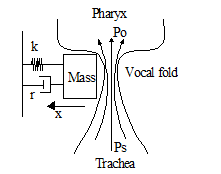

6.1. Human Voice Production

The example of phonetics of filtering sound of a human speech is illustrated. The human speech is synthesized due to development of stresses at vocal folds [16-17]. The smoothening of the sound is function of its amplitude and its shape of oscillations at vocal tract of a human being. The vocal tract is a resonant cavity wall with sound energy stored in oscillations of its vocal folds. The vocal chords showing mechanism of synthesis of human speech is illustrated in Figure 1.

Figure 1: A human vocal mechanism

Figure 1: A human vocal mechanism

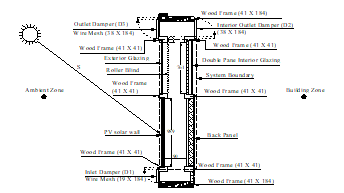

6.2. An Airflow Window with a Photovoltaic Solar Wall

The filtering of solar energy is illustrated through an example of an airflow window attached with a shading device. An airflow window is fixed with a movable roller blind to control the transmission of daylight as well as amount of solar heat. The bottom portion of photovoltaic solar wall is used for controlling the amount of air ventilation along with generation of solar electric power. The example is illustrated in Figure 2.

Figure 2: An Airflow window with a Photovoltaic Solar Wall (Dimensions shown are in mm).

Figure 2: An Airflow window with a Photovoltaic Solar Wall (Dimensions shown are in mm).

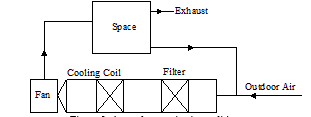

6.3. Psychrometric Air Conditioner

An elementary air conditioner for summer comfort conditioning consists of a cooling coil, a cooling fluid with a filter [18]. The schematic of operation of a psychrometric air conditioner is illustrated in Figure 3.

Figure 3. A psychrometric air conditioner

Figure 3. A psychrometric air conditioner

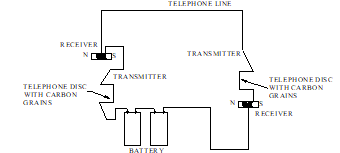

6.4. Telephone Line

The impedance of a telephone line is composed of distributed resistance, capacitance, and inductance [19]. The impedance of telephone line is proportional to the insulation, loop length and whether the wire is buried, aerial or bare parallel wires strung on telephone pole. A telephone line is usually supplied with a 48 VDC from the telephone exchange. The schematic of operation of a telephone line with telephone instrument is illustrated in Figure 4.

Figure 4: Operation of a Telephone Line.

Figure 4: Operation of a Telephone Line.

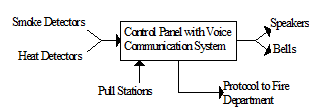

6.5. Fire and Smoke Detection System

A fire detection system consists of a control system with interconnected alarms, smoke and heat detectors. A fire detector is a device which is used for presetting an alarm at a particular temperature. A smoke detector is a device which is used for presetting an alarm when a certain percentage of smoke accumulates. The photovoltaic cell activates the smoke alarm only if it senses requisite obscuration of light over a unit area with control from BMS [20]. The schematic of various components for fire detection system is illustrated in Figure 5. The detail description of a fire alarm systems is provided later in discussions.

Figure 5: A fire detection system

Figure 5: A fire detection system

7. Experiments

Many studies on facade integrated PV system are focused on the model simulation of radiation and convection [21-36]. Kim and Kim [28] compared three different types of integrated PV-thermal system configurations. The study analyzed the system performance as well as the building performance. Various researchers [29-30] have also conducted research on the energy performance and efficiency of actively air cooled PV modules integrated into facades.

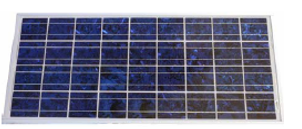

In the present study, the salient feature of a pair of PV modules used in solar wall was the glass coating surrounding the semiconductor material of solar cells [24-25]. The manufacturing of glass coated PV modules was based on multi-crystalline solar cell technology. The operating conditions were selected for conducting various experiments on a PV solar wall. The indoor solar simulator tests were conducted for PV modules under standard operating conditions. The outdoor tests were conducted under available climatic conditions for obtaining temperatures, air velocities, thermal time constants, heat capacity, and thermal storage capacity of a PV solar wall. The PV modules used for experiments were having a glass coating of 3 mm attached on its exterior and interior sides. The glass coating was attached to exterior and interior sides of PV modules in the form of glass sheets by a double-glass (PWX) manufacturing technology. Each PV module was having 36 multi-crystalline solar cell units, with thin transparent gaps in between them. The glass coating on PV modules has improved the overall performance of PV modules in many ways; it has: i) protected semi-conductor material from weather deterioration; ii) absorbed ultra violet rays of solar energy and trap solar heat in glass coating, thus increasing the temperature of the surrounding environment; iii) reduced the reflection losses of sunlight rays reflected from PV module; iv) improved the aesthetic appearance of PV module; v) increased the thermal mass of PV module; and vi) enhanced the structural strength of PV module. The pictorial view of glass coated PV module used in experiments is illustrated in Figure 6. The typical characteristics of glass coated PV module without frame were: dimensions of 993 mm by 453 mm and a thickness of 6.2 mm with glass coating, typical current of 2.8 A, typical voltage of 17 V, temperature coefficients of current and voltage were + 0.034 %/°C and -2.17 mV/°C/solar cell at standard test conditions [2, 24].

Figure 6: Glass coated PV module used in experiments

Figure 6: Glass coated PV module used in experiments

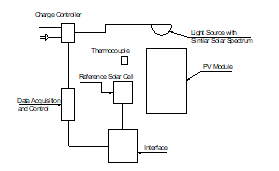

The indoor measurement tests were carried out in an indoor simulation test facility of CANMET Energy Technology Centre of Natural Resources, Varennes, Québec, Canada [2]. The schematic of indoor solar simulator used for establishing characteristics of glass coated PV modules is illustrated in Figure 7.

Figure 7 Block diagram of an indoor solar simulator

Figure 7 Block diagram of an indoor solar simulator

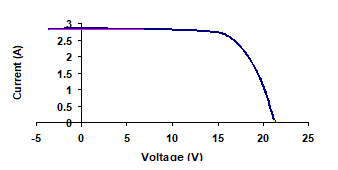

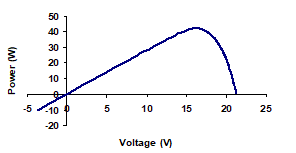

The current-voltage and power-voltage characteristics of one of the PV modules are shown in Figs. 8 and 9 [2]. Table 2 has presented characteristics of a pair of PV modules established with an indoor solar simulator [2]. As presented in Table 2, electrical conversion efficiency to the order of 8.9% was reported from indoor simulator tests. The current-voltage and power-voltage characteristics of tested PV module are illustrated in Figs. 8 and 9.

Table 2: Characteristics of glass coated pv modules established with an indoor solar simulator

|

PV Module |

Solar Intensity (Wm-2) |

Spectrum |

Isc (A) |

Voc (V) |

| PW30 | 1009.11 |

1.5 A.M. Class B |

2.833 | 21.296 |

| PW31 | 1007.58 |

1.5 A.M. Class B |

2.829 | 21.352 |

|

PV Module |

Vmax (V) |

Pmax (Watts) |

Fill factor |

Efficiency (%) |

| PW30 | 16.198 | 42.157 | 0.6985 | 8.703 |

| PW31 | 16.503 | 43.435 | 0.7188 | 8.981 |

Figure 8: Current-voltage characteristics of PW30

Figure 8: Current-voltage characteristics of PW30

After determining current-voltage and power-voltage characteristics from an indoor solar simulator, the pair of glass coated PV modules was installed in the test section of an outdoor test-room. The outdoor experiments were conducted on PV modules in order to determine energy conversion characteristics and further improving the overall performance of PV modules by using thermal mass of an outdoor room.

Figure 9: Power-voltage characteristics of PW30

Figure 9: Power-voltage characteristics of PW30

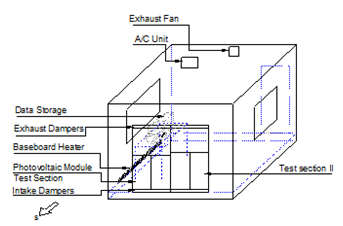

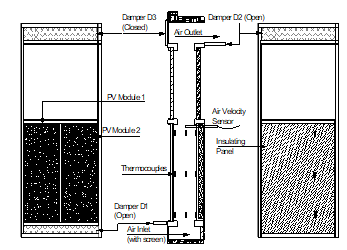

The outdoor room was a pre-fabricated structure that was delivered into the premises of Concordia University in Montréal, Québec, Canada for conducting experiments on glass coated PV modules [2]. The test section with vertical PV modules, was aligned 10° East of South for receiving maximum solar radiation between 8.00 and 14.00 hrs solar time and also avoiding shading from adjacent buildings. The schematic of an outdoor room used for conducting outdoor experiments is illustrated in Figure 10. The outdoor experiments were conducted on a solar wall section built with two commercially available glass coated PV modules, an air passage with gap width of 90 mm, an insulating panel, side walls made up of Plexiglas and connected wooden frames. The insulation panel was assembled with 7 mm thick plywood board enclosure filled with 26 mm polystyrene. The steady state average resistance of the composite plywood board-polystyrene section of insulation panel obtained from the heat flow meter test was 1.0 m2 °C W-1 [2]. The side wall of wooden frame was fixed with Plexiglas of thickness 12 mm (k = 0.1316 W m-1 K-1) placed perpendicularly facing air-gap for view of the air passage from inside the test room.

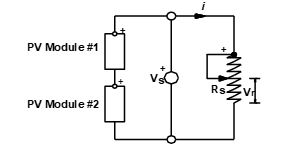

A series electrical circuit connection was established for a pair of vertical PV modules installed on a solar wall for determining the current-voltage measurements and electric power output. The electrical circuit for two PV modules connected in series for generation of electric power with a rheostat of maximum varying resistance up to 50 Ω is illustrated in Figure 11. A circular variable resistor of 50 Ω was a wire-wound coil with a sliding contact that was used to vary electrical resistance without interrupting the current. The Joule heating at a rate of 73 cal/s (305 W) was predictable at a typical current rating of 2.8 A for a PV module. The null resistance of rheostat was calculated to be 39 Ω at a current of 2.8 A, which was not having any potential difference across it. In Figure 6, the sliding contact of rheostat has a resistance of Rs, with a current (i= Vr/Rs) flowing across the circuit; Vr is potential difference across the resistance, Rs.

The passive air ventilation was created in the PV module test section by natural wind or through buoyancy effect in the absence of wind. The active fan pressure was used to achieve higher air velocities by operation of the exhaust fan fixed on opposite façade with respect to the PV test section. The slight negative pressure was induced for drawing low air velocities in absence of wind-induced pressure from the inlet damper into the PV test section through the outdoor room. The exhaust ventilation fan was rated at 270 CFM (ft3/min) (0.127 m3 s-1) at standard atmospheric pressure so as to create between 10-25 Pa of negative pressure depending on the air leakage from the outdoor room.

Figure 10: Schematic of a pre-fabricated outdoor room with PV solar wall test section

Figure 10: Schematic of a pre-fabricated outdoor room with PV solar wall test section

Figure 11: Electric circuit for PV modules

Figure 11: Electric circuit for PV modules

The air velocities near the exit of PV modules were obtained both as a measure of buoyancy and fan induced hybrid ventilation. The fan pressure was created with an exhaust fan fixed on wall of an outdoor room opposite to wall with a wooden frame installed with glass coated PV modules. The air velocity sensor was placed perpendicular to the walls of the PV solar wall section for measuring axial air velocities near its outlet.

In order to minimize boundary layer effect in air velocity measurement, air velocity sensor was placed at middle air-gap width at a distance of 45 mm from either of the walls of the PV solar wall. To minimize turbulence effects in air velocity measurement, air velocity sensor was placed near the outlet (at 1100 mm from the bottom) of the PV test section with total air passage length of 2100 mm in the test section. To minimize three-dimensional effect in air velocities, fan-induced active ventilation was achieved by developing air velocities by the induced draft fan fixed on the opposite wall so that it was placed at a distance from the walls of PV module test section. It was validated by one of the experiments that measured surface temperatures of the two adjacent glass coated PV modules were within ±0.5 °C under similar operating conditions.

7.1. Outdoor Measurements

Three thermocouple sensors were placed at the top, middle, and bottom locations in the PV module, air-passage, and insulating panel. They were used to measure their local temperatures at their defined fixed positions. Two thermocouples were used to measure the inside test room air temperature and ambient air temperature. One differential thermocouple was used to check the air temperature difference between top and bottom sections of the PV module test section. The thermocouple outputs, current, voltage, solar irradiation, and air velocity signals were connected to a data logger and a computer for data storage. The copper-constantan junction (T-type) thermocouples were used for measurements for generating voltage signals to the data logger. As mentioned earlier, the air velocity sensor (make-Dwyer instruments, model no. 640-0) was used to collect air velocity measurements. The solar intensity measurements were collected with a photometer sensor fixed on the south wall of an outdoor room. The schematic of outdoor experimental apparatus for a PV solar wall device is illustrated in Figure 12.

7.2. Temperature Plots

The measurements collected from the sensors were recorded in a data logger as a function of air velocities through a PV solar wall for the cases of passive ventilation and active ventilation with use of fan pressure. Similarly, temperature measurements were obtained from the PV solar wall section as a function of air velocities. The temperatures for PV module, air passage, and insulating panel in the PV solar wall were obtained. The sample measurements obtained from outdoor experimental setup are presented in Table 3.

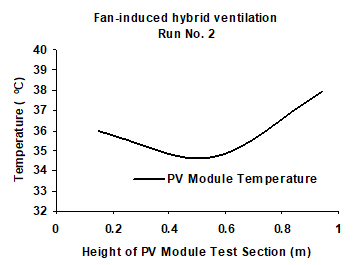

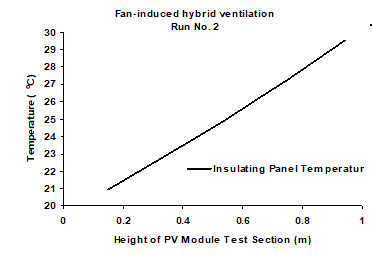

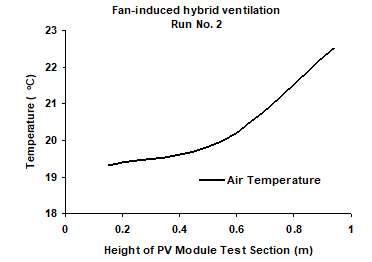

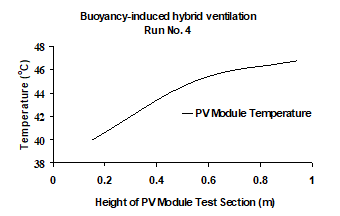

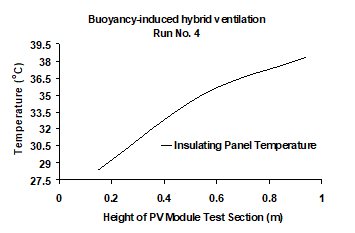

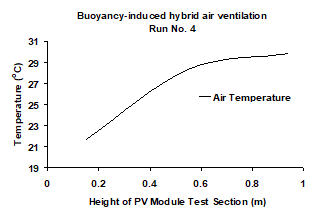

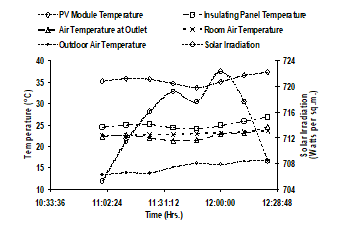

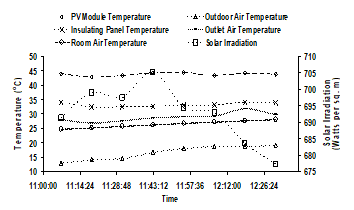

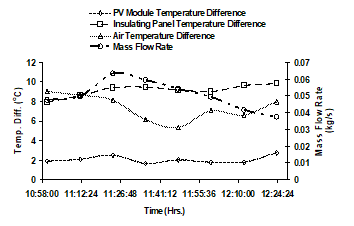

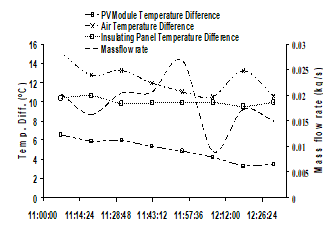

The temperature plots for PV module, insulating panel, and air for different conditions of ventilation are illustrated in Figs. 13 and 14. The temperature plots with respect to height of a PV solar wall for the data provided in Tables 3 to 5 are obtained. The variation of mean temperatures of PV module, insulating panel, and air in a PV solar wall with approximately steady solar noon irradiation with varying air velocities for the case of active ventilation and passive ventilation are illustrated in Figs. 15 to 16. Temperature differences for various cases of ventilation are provided in Figure 17(a) and 17 (b).

Figure 12: Schematic of outdoor experimental apparatus for a PV solar wall installed on a wooden frame

Figure 12: Schematic of outdoor experimental apparatus for a PV solar wall installed on a wooden frame

7.3. Sensible Heat Storage Capacity

The PV solar wall test section with wooden frame was composed of non-homogeneous materials having different densities, specific heats, and thicknesses. The pair of PV modules was fixed with three layers of material, viz. a flat sheet of solar cells, glass sheets on its exterior and interior sides. It was assumed that surface temperature of PV module was uniformly distributed in the three layers. It was also assumed that the heat capacity of the wooden frame and sealing material was having little effect on the temperature of PV module, air or insulation panel. This was because of the fact that wood was used as a construction material, and moreover, the magnitude of the heat capacity of wood framing material was not proportional to the face area of glass coated PV modules. The sensible heat capacities of glass faces, solar cells, air and polystyrene filled plywood board are presented in Table 4. It was observed that the difference of temperatures recorded by the top and bottom sensors for PV module, air and insulating panel were 6.9 °C, 8.1 °C, and 9.9 °C, respectively, for the critical case of passive ventilation of Run no. 4 in Table 3. Furthermore, the temperature differences were used for obtaining sensible heat storage capacities of various components in y-ordinate. The heat storage capacities obtained were 59.6 kJ, 0.755 kJ, and 510.7 kJ for PV module, air and insulation panel respectively. The heat capacities obtained were negligible in comparison with the total daily solar irradiation on PV modules on the day of conducting the outdoor experiments. It was also assumed that there were constant surface properties and ideal still air at the instance of collection of the measurements. Heat storage capacity in x-ordinate was also obtained from the similar procedure by assuming same proportionate temperature difference along thicknesses in x-ordinate. It was found that heat capacity in x-ordinate was nil in comparison with the value of heat capacity obtained for y-ordinate.

Table 3: Outdoor Measurement

| Run No. |

S (W m-2) |

Ep (W) |

To (°C) |

Ts (°C) |

V (m s-1) |

||||||||

| Active ventilation (Fan-assisted) | |||||||||||||

| 1 | 716.1 | 30.7 | 15.2 | 22.4 | 0.68 | ||||||||

| 2 | 716.1 | 30.7 | 13.4 | 22.4 | 0.53 | ||||||||

| Passive ventilation (Buoyancy-induced) | |||||||||||||

| 3 | 697.5 | 28.9 | 13.2 | 25.1 | 0.13 | ||||||||

| 4 | 697.5 | 28.8 | 13.3 | 24.9 | 0.17 | ||||||||

| Run No. |

Tp(b) (°C) |

Tp(m) (°C) |

Tp(t) (°C) |

Tb(b) (° C) |

Tb(m) (°C) |

Tb(t) (°C) |

Ta(b) (°C) |

Ta(m) (°C) |

Ta(t) (°C) |

||||

| Active ventilation (Fan-assisted) | |||||||||||||

| 1 | 35.4 | 33.8 | 36.8 | 20.6 | 24.7 | 29.1 | 18.8 | 21.7 | 19.4 | ||||

| 2 | 35.9 | 34.6 | 37.9 | 20.9 | 25.0 | 29.5 | 19.3 | 22.5 | 19.9 | ||||

| Passive ventilation (Buoyancy-induced) | |||||||||||||

| 3 | 40.8 | 44.9 | 46.8 | 27.9 | 34.8 | 38.0 | 21.3 | 29.5 | 29.8 | ||||

| 4 | 39.9 | 45.0 | 46.8 | 28.4 | 35.0 | 38.3 | 21.7 | 28.3 | 29.8 | ||||

| Distance as per locations shown in Figure 7 |

Tp(b) (°C) |

Tp(m) (°C) |

Tp(t) (°C) |

Tb(b) (°C) |

Tb(m) (°C) |

||||||||

| y (cm) | 15 | 55 | 94 | 15 | 55 | ||||||||

| z (cm) | 60 | 60 | 60 | 60 | 60 | ||||||||

| x (mm) | 6.2 | 6.2 | 6.2 | 96.2 | 96.2 | ||||||||

| Distance as per locations shown in Figure 7 |

Tb(t) (°C) |

Ta(b) (°C) |

Ta(m) (°C) |

Ta(t) (°C) |

Air velocity sensor | ||||||||

| y (cm) | 94 | 15 | 55 | 94 | 99 | ||||||||

| z (cm) | 60 | 60 | 60 | 60 | 60 | ||||||||

| x (mm) | 96.2 | 51.2 | 51.2 | 51.2 | 51.2 | ||||||||

| Note: x is horizontal; y is vertical; z is adjacent 3rd axis of x-y plane | |||||||||||||

Figure 13: (a) Temperature plot of PV module for fan-assisted ventilation with height of PV solar wall section

Figure 13: (a) Temperature plot of PV module for fan-assisted ventilation with height of PV solar wall section

Figure 13: (b) Temperature plot of insulating panel for fan-assisted ventilation with height of PV solar wall section

Figure 13: (b) Temperature plot of insulating panel for fan-assisted ventilation with height of PV solar wall section

Figure 13: (c) Temperature plot of air for fan-induced hybrid ventilation with height of PV solar wall section

Figure 13: (c) Temperature plot of air for fan-induced hybrid ventilation with height of PV solar wall section

Table 4: Sensible heat storage capacities

| Component |

ρn (kg m-3) |

Cn (J kg-1 K -1) |

dn (m) X 10-3 |

dnρnCn (J m-2K-1) |

Hpv-T (J K-1) |

| Glass coating | 3000 | 500 | 3 | 4500 | 4171.5 |

| PV module | 2330 | 677 | 0.2 | 315.48 | 292.45 |

| Glass coating | 3000 | 500 | 3 | 4500 | 4171.5 |

| Sub-total | – | – | – | – | 8635.5 |

| Air | 1.1174 | 1000 | 90 | 100.56 | 93.22 |

| Plywood | 550 | 1750 | 7 | 6737.5 | 6245.66 |

| Polystyrene | 1050 | 1200 | 26 | 32760 | 30368.5 |

| Plywood | 550 | 1750 | 7 | 6737.5 | 6245.66 |

| Sub-total | – | – | – | – | 42953.0 |

| Total | – | – | – | – | 51588.5 |

Note: Heat capacities were calculated for face area of PV module test section of 0.927 m2.

Figure 14: (a) Temperature plot of PV module for buoyancy-induced hybrid ventilation with height of PV solar wall section

Figure 14: (a) Temperature plot of PV module for buoyancy-induced hybrid ventilation with height of PV solar wall section

Figure 14: (b) Temperature plot of insulating panel for buoyancy-induced hybrid ventilation with height of PV solar wall section

Figure 14: (b) Temperature plot of insulating panel for buoyancy-induced hybrid ventilation with height of PV solar wall section

Figure 14: (c) Temperature plot of air for buoyancy-induced hybrid ventilation with height of PV solar wall section

Figure 14: (c) Temperature plot of air for buoyancy-induced hybrid ventilation with height of PV solar wall section

Figure 15: Variation of mean temperatures of PV module, air and insulating panel with solar irradiation under fan-induced hybrid ventilation

Figure 15: Variation of mean temperatures of PV module, air and insulating panel with solar irradiation under fan-induced hybrid ventilation

Figure 16: Variation of mean temperatures of PV module, air and insulating panel with solar irradiation under buoyancy-induced hybrid ventilation

Figure 16: Variation of mean temperatures of PV module, air and insulating panel with solar irradiation under buoyancy-induced hybrid ventilation

Figure 17(a): Temperature difference for PV module, insulating panel and air with height of PV solar wall under fan-induced hybrid ventilation

Figure 17(a): Temperature difference for PV module, insulating panel and air with height of PV solar wall under fan-induced hybrid ventilation

Table 5: Thermal storage capacities

| Component |

kd (W m-1 K-1) |

dnρnCn (J m-2K-1) |

Hd (Wm-2K-1) |

T (sec) |

ΔTV (K) |

ΔTH (K) |

QV (kJ) |

QH (J) |

| PV module | 0.91 | 9315.48 | 10 | 932 | 6.9 | 0.04 | 5.8 | 0.2 |

| Air | 0.02624 | 100.56 | 10.0 | 10 | 8.1 | 0.75 | 0.0 | 0.0 |

| Plywood | 0.0835 | 6737.5 | 10.0 | 674 | 9.9 | 0.40 | 0.55 | 0.16 |

| Polystyrene | 0.02821 | 32760 | 1.0 | 32760 | 9.9 | 0.40 | 9.0 | 9.6 |

| Plywood | 0.0835 | 6737.5 | 10.0 | 674 | 9.9 | 0.40 | 0.55 | 0.16 |

| Total | – | – | – | – | – | – | 15.9 | 10.12 |

Notes:

- Equivalent thermal conductivity of glass coated PV module was calculated to be 0.91 W m-1 K-1

- Temperature differences along y-direction i.e. along height of PV module test section (0.993 m) were obtained from Table III for Run No. 4 in the case of buoyancy-induced hybrid ventilation.

- Temperature differences along x-direction i.e. along thicknesses of each component of PV module test section were obtained proportionate to temperature differences along y-direction.

Table 6: Temperature difference and noise of sol with solar irradiation (air velocity: 0.75 m·s-1)

|

Solar irradiation (W·m-2) |

Air Temperature Difference (ΔT) °C |

Noise of Sol oS (oncisol) |

| 450 | 15.50 | 28 |

| 550 | 18.90 | 28.93 |

| 650 | 22.40 | 29.7 |

| 750 | 25.90 | 30.36 |

| 850 | 29.40 | 30.91 |

Table 7: Temperature difference and noise of scattering with air velocity (S = 650 W·m-2)

| Air velocity (m·s-1) | Fluid Power (W·m-2) | Air Temperature Difference (ΔT) °C |

Noise of Scattering oS (oncisip) |

| 1.35 | 47.62 | 15.28 | 17.72 |

| 1.05 | 37.0 | 18.22 | 16.50 |

| 0.75 | 26.45 | 22.40 | 15.02 |

| 0.45 | 15.87 | 28.15 | 12.65 |

| 0.15 | 05.29 | 29.80 | 07.64 |

Table 8: Mass flow rate and noise of therm with (ΔT) °C

| (ΔT) °C |

Mass flow rate (Kg·s-1) |

Thermal Power (W·m-2) |

Noise of Therm oS (oncisol) |

(ΔT) °C | Mass flow rate (Kg·s-1) |

Thermal Power (W·m-2) |

Noise of therm oS (oncisol) |

| 15.50 | 0.01376 | 71.09 | 19.5602 | 15.28 | 0.0231 | 117.65 | 21.868 |

| 18.90 | 0.01275 | 80.325 | 20.119 | 18.22 | 0.0171 | 103.85 | 21.296 |

| 22.40 | 0.0120 | 89.6 | 20.614 | 22.40 | 0.0120 | 89.6 | 20.614 |

| 25.90 | 0.0115 | 99.2833 | 21.043 | 28.15 | 8.1 X 10-3 | 76.0 | 19.866 |

| 29.40 | 0.0111 | 108.78 | 21.505 | 29.80 | 6.2 X 10-3 | 61.59 | 18.898 |

Table 9: Noise of elasticity with air particle velocity (Impedance Z0 = 413 N·s·m-3 at 20°C)

|

Air velocity (m·s-1) |

Fluid Power (W·m-2) |

Noise of Scattering oS (oncisip) |

Sound Pressure (N·m-2) |

Sound Power Intensity (W·m-2) |

Noise of Elasticity oB (oncibel) |

| 1.35 | 47.62 | 17.72 | 557.5 | 752.7 | 30.36 |

| 1.05 | 37.0 | 16.50 | 433.65 | 455.33 | 28.05 |

| 0.75 | 26.45 | 15.02 | 309.75 | 232.31 | 24.97 |

| 0.45 | 15.87 | 12.65 | 185.85 | 83.63 | 20.24 |

| 0.15 | 05.29 | 07.64 | 61.94 | 09.29 | 10.12 |

Figure 17(b): Temperature difference for PV module, insulating panel and air with height of PV solar wall under buoyancy-induced hybrid ventilation

Figure 17(b): Temperature difference for PV module, insulating panel and air with height of PV solar wall under buoyancy-induced hybrid ventilation

8. Numerical Model

The initial boundary values in the model are based on the measured values of quasi steady-state solar irradiation, ambient air temperature, and room air temperature and air velocities. The measured boundary values were then used to obtain solutions for heat equations of the photovoltaic solar wall section. The actual observed temperatures from the experimental apparatus were then compared with the simulated temperatures obtained from the model.

The results of noise unit calculations using Equations 2, 4 and 6 for an outdoor duct exposed to solar radiation are tabulated in Tables 6 to 9. The results of the 2-D numerical model are presented in Table 10 and are obtained by assuming constant fluid and surface properties.

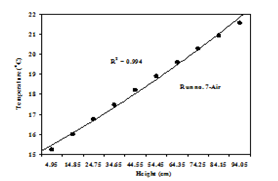

The variation of temperature of air with height of the photovoltaic solar wall test section is illustrated in Figure 18. Figure 18 also illustrates the deviation caused in the proposed model solution in comparison with the ideal exponential or logarithmic temperature variation.

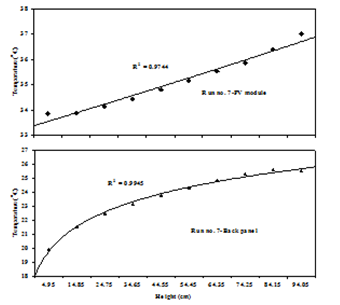

The profiles of surface temperatures of PV module and back panel along the height of the solar wall section are illustrated in Fig, 19. The deviation from the ideal exponential and logarithmic temperature profiles of PV module and back panel is also presented in Figure 19. It was observed that significant cooling of surface of PV module was achieved by radiation heat exchange with the back panel. The surface temperatures of PV module and back panel for four different runs representing variation in solar intensities are presented in Table 10.

8.1. Thermal Time Constant

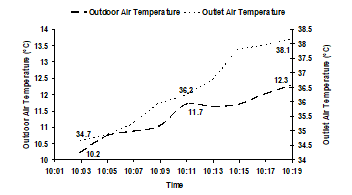

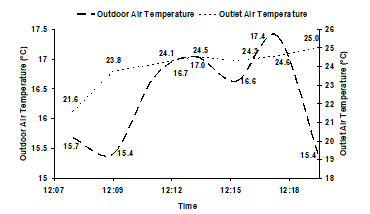

The thermal time constant is defined as the time required for the outlet air temperature to attain 63.2% of the total difference in value attained in air temperature following a step change in temperature of outdoor air crossing the inlet opening of the PV solar wall. Data for a step change were selected for observing the ambient air temperature. The data selected were in a steady state before and after the time-interval during the unsteady state response of the outlet air temperature with the step change in ambient air temperature. From the graphs, it was observed that thermal time constant under passive air ventilation was between 8-10 minutes in comparison to 2 minutes under active air ventilation. Therefore, it was decided that duration of time.

Figure 18: Temperature profile for Air for S=725.4 W m-2 (Run no. 7)

Figure 18: Temperature profile for Air for S=725.4 W m-2 (Run no. 7)

interval was selected for a minimum of two minutes to record any subtle temperature changes for obtaining measurements from the data logger [34]. The graphs of ambient and outlet air temperatures were plotted against the time-interval of measured data for the two cases of passive and active ventilation are presented in Figure 20(a) and 20 (b). Thermal time constants of the PV solar wall section were function of ambient air temperatures and air velocities and were therefore approximately calculated under conditions of passive and active air ventilation.

Figure 19: Temperature profile for PV module and Back Panel for S=725.4 Wm-2 (Run no. 7)

Figure 19: Temperature profile for PV module and Back Panel for S=725.4 Wm-2 (Run no. 7)

Figure 20 (a): Changes in outlet air temperature from a PV solar wall with a step change in outdoor air temperature under passive (buoyancy-induced) ventilation

Figure 20 (a): Changes in outlet air temperature from a PV solar wall with a step change in outdoor air temperature under passive (buoyancy-induced) ventilation

Figure 20 (b): Changes in outlet air temperature from a PV solar wall with a step change in outdoor air temperature under active (fan-induced) ventilation

Figure 20 (b): Changes in outlet air temperature from a PV solar wall with a step change in outdoor air temperature under active (fan-induced) ventilation

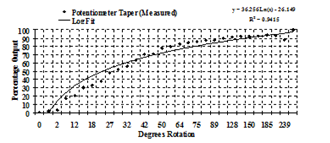

Figure 21: Potentiometer Taper (Measured) with percentage voltage output

Figure 21: Potentiometer Taper (Measured) with percentage voltage output

8.2. Photovoltaic Amplification

In a parallel plate PV device, the temperatures were measured as a function of its volume. The measurements of temperatures for PV modules, insulating panel and ventilated air column in the wooden frame were non-linear. In the ventilated PV solar wall device for transportation of heat, the air velocities were developed both as a measure of buoyancy-induced and fan-assisted ventilation. The measurements of PV solar wall device, ambient air and room air temperatures, air velocities and solar intensities are presented in Table 10. The location and nomenclature of sensors is presented in Table 3. The power output results from a potentiometer with rotation of its circular knob are illustrated in Figure 21. From the graphs of Figs. 13, 14, 18, 19 and 20, phenomenon of photovoltaic amplification is observed. For a PV solar wall device, the gain is a function of its resistance or volume of steady state thermal and electrical functions. A loudspeaker has similar operational characteristics.

9. Signal Processing Parameters for a PV Device

The sinusoidal steady-state response was applied in performing the analysis of the parallel plate PV device circuit, because of the advantage of representing a periodic function in terms of a sinusoidal exponential function. Electrical analog RC circuit parameters of a parallel plate PV device are enumerated as under [4, 22]:

Capacitance: The capacitance of a parallel plate PV device with air as a dielectric medium was calculated to be 91.2 picofarads.

Resistance: The electrical resistances of various components were calculated as: glass coated PV modules were approximated as 5.3 kΩ, air was approximated as 1200 MΩ, and plywood board was approximated as 26.5 Tera Ω. The total equivalent electrical resistance of a parallel plate PV solar wall device was approximated as: 5.3 kΩ.

Time Constant: The time constant, which is product of resistance and capacitance, was calculated to be: 0.5 microseconds. The frequency with this time constant was calculated to be 2 MHz.

Capacitive Reactance: The capacitive reactance was calculated to be: 872.5 Ω.

Impedance: The impedance of the circuit was calculated to be: 5.4 kΩ.

The Phase angle θ: The phase angle between capacitance and reactance was calculated to be 9°.

The Phasor representation:

Z = 5.300 – j 0.8725 = 5.4 kΩ ∟-9°.

Capacitive Heating: The joule law gives instantaneous power absorbed by the capacitive impedance which is converted to heat. The heat capacities under critical operation of buoyancy-induced ventilation were calculated to be 59.6 kJ, 0.755 kJ and 510.7 kJ for PV module, air and plywood board respectively. The total average value of joule heating for the parallel plate PV device was calculated to be 571 kJ.

Induction Losses: The induction losses due to thermal storage effect in the parallel plate PV device were calculated to be 15.9 KJ.

Power Factor: The power factor was calculated to be cos θ = 0.911 lag.

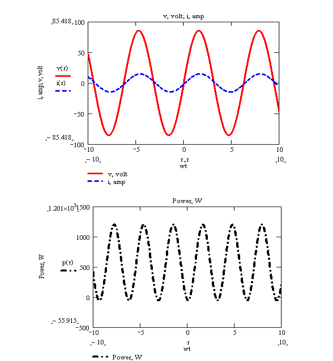

Current function (i2(t)): Using the current function, i2(t) = Im2sin2(ωt + θ), the effective (root mean square) value of current was calculated to be 10.4 amps and maximum value of current was calculated to be 14.71 amps.

Voltage function: The voltage function is defined as per the sine wave: v = Vm.sin(ωt). The effective value of the voltage was calculated to be 60.4 volts and maximum value of the voltage was calculated to be 85.42 volts.

Power function: The instantaneous power is given by the expression:

![]() The Plots: The time diagram for current, voltage is plotted in Figure 22 (a). The time diagram for power is plotted in Figure 22 (b).

The Plots: The time diagram for current, voltage is plotted in Figure 22 (a). The time diagram for power is plotted in Figure 22 (b).

Figure 22 – Time diagrams: (a) voltage and current; (b) power in a RC circuit amplifier

Figure 22 – Time diagrams: (a) voltage and current; (b) power in a RC circuit amplifier

Power Transfer: To describe the resonance phenomenon for equivalent mechanical, hydraulic and thermal systems of PV solar wall device, an electrical analog was used.

The Figure 22 shows that the instantaneous power is negative whenever the voltage and current are of opposite sign. However, as is illustrated in the Figure 22 that positive area of p(t) energy exceeds the negative area. Therefore, the average power is finite. Since the angle, θ, is small between current and voltage, the negative area of energy become very small. The induction losses due to thermal storage amount to 1.5% in comparison to the capacitive heating. Thus induction losses cannot be avoided in any electrical circuit, but can be minimized.

10. Solar Energy Acoustics

10.1. Theory

A theory of acoustics in solar energy was proposed by the author [10], which can be arrived and deduced from definitions of Noise of Sol and Equations (1) and (2).

A brief on the theory of a solar energy absorber is presented here in this paper. On the transparent surface of a solar energy absorber, direct rays from the sun are incident. The diffuse rays from the sky, clouds, and surrounding objects are also incident, which is also partly reflected and partly transmitted from a solar energy absorber. In addition to this, the selective coating on the surface of a solar energy absorber absorbs some part of the radiation. The reflected part of the incident flux is called the reflectance p, the absorbed part of radiation is called the absorptance α, and the transmitted part of radiation is called the transmittance τ. The sum of absorptance, transmittance and reflectance is unity, or

α + τ + p = 1 (8)

There are non-constant distributions of radiations over the directions of incidence and over the wavelength (or frequency) scale on a solar energy absorber. A sample of selective material of a solar energy absorber has radiation properties of transmittance, reflectance and absorptance, which are function of a specific thickness. For a solar energy absorber, the emittance ε is defined as the division of the thermal radiant flux emission from a surface to the black body radiant flux emitted at the same temperature.

The evaluation of radiation properties from angular dependence point of view is explained through geometry theory of a solid angle formed by all rays joining a point to a closed curve. The solid angle is defined as the ratio of the projected area A on the sphere to the square of length R and radius R. A sphere is considered to be having a solid angle of 4π steradians. For a solar energy absorber, the solar radiation incident on a point at a surface is presumed to be coming from many directions in a conical solid angle. For a cone of half angle θ, the solid angle defined by the circular top of the cone and point bottom of that cone is given by expression as:

Ω = 2 π (1-cos θ) (9)

In measuring the transmittance or reflectance, a sample is illuminated over a specified solid angle. The flux is then collected for a given solid angle for measurement of reflectance or transmittance. A conical solid angle is bound through a right circular cone. The source of solar radiation is sunlight.

The radiation properties of sunlight essential for performance analysis of daylighting and lighting are defined as follows:

The luminous flux is directed outward from a source, it ultimately strikes on many surfaces, where it is reflected, transmitted and absorbed. The illuminance is the density of the luminous flux incident on that surface.

The luminance is defined as the intensity of the source or the sink in the direction of an observer divided by the area projected on the source or sink as viewed by an observer.

Luminous intensity is defined as the power due to generation of the luminous flux. A source of sunlight is depicted to be having a luminous intensity in a particular direction. The inverse square law demonstrate that the illuminance incident perpendicular to the line from the point source of sunlight to the surface is directly proportional to the intensity of the source and inversely proportional to the square of the distance from the source of sunlight to the incident surface.

The luminous flux is defined as the rate of flow of light. A receiver surface receives watts of sunlight and it emits luminous flux. The measure of the success rate in converting watts of sunlight to lumens is called efficacy.

Quantity of sources is defined as luminous energy and is related to luminous flux, which is luminous power per unit time.

The luminance exitance is defined as the density of luminous flux leaving a surface of a solar energy absorber. The reflectance is defined as the ratio of the luminous flux reflected from a surface to the luminous flux incident on that surface. The transmittance is defined as the ratio of the luminous flux transmitted through a surface to that incident on the same surface.

10.2. Source and Sink of Solar Energy

The planet earth and its surrounding environment is absorber of solar energy. Examples of solar energy absorbers are civil structures such as green houses, buildings, panels, collectors, thermal power plants, roads, ports, bridges and canals. The earth-atmosphere system is an absorber for a portion of the incident solar energy radiated from the sun. The surface of the earth is also heated by a flux from its interior region from the decay of radioactive isotopes of the earth. The tides on earth occur due to the earth-moon system, result in viscous friction, energy input that affects the surface energy balance of the earth. To the extent that the earth is at a steady state and is not changing, the heat radiated by the surface of the earth is equal to the sum of the heat inputs. The solar radiation sources consist of many waves of interference in its radiation spectrum. The absorbed sources of waves of interference of light, sound, heat, electricity, fluid, fire are function of absorptivity for a solar intensity. The sink of solar energy is the earth and its earth-moon system. The temperature of the earth is raised by absorbed solar radiation as incident solar energy is the dominant energy input. The radiation absorbed by the earth is proportional to the earth’s cross-sectional area perpendicular to the sun’s flux. The earth is acting as a black body radiator with actual power radiated by the earth is determined from the radiative temperature of the earth-atmosphere system.

10.3. Radiation Sources and Life on Earth

Life on the earth is completely dependent upon the energy radiated by the sun. By photosynthesis green plants convert solar energy into chemical energy. All biological processes are either directly or indirectly reliant upon photosynthesis. In addition to the primary role of light in a living economy, a constant environment of radiations from various sources produces other effects, reactions and adaptations. These radiations have receptiveness to influence the life activities. The solar radiation, while passing through the atmosphere is reflected, scattered, and absorbed by gas molecules, ozone, water vapour, clouds and dust. The atmospheric length path traveled by sun rays is obtained by the air mass m, which is the ratio of the mass of atmosphere to the mass which would exist if the sun was directly overhead at sea level. In this case of overhead earth-sun path, m is equal to 1.0.

The sunlight on the earth is the major source of radiations. The spectrum of sunlight constitutes ultraviolet radiation, visible light, infrared rays and radio waves. The x-rays are originated by solar flares and their ionization due to absorption happens high in the earth’s atmosphere. From various celestial sources, x-rays also reach the earth’s atmosphere. About 60 per cent of the sunlight energy is in the invisible infrared region’s indefinite limit in radiation spectrum. Before radiations of shorter wavelengths reach the surface of earth, they are absorbed in the earth’s atmosphere. The artificial radioactive elements are produced by bombardment through high energy particles, examples include helium nuclei. The radioactive emanations consist of three components: i) alpha particles, which are positively charged helium nuclei; ii) gamma rays, which are penetrating radiations of very short wavelength but otherwise like x-rays; and iii) beta particles, which are rapidly moving electrons.

10.4. Greenhouse Gases

The most of ultraviolet solar radiation is absorbed by the ozone in the upper atmosphere. The part of the solar radiation in the shortwave region is scattered by the air molecules. The ozone layer is formed high above the atmosphere through absorption of ultraviolet radiation by oxygen. The reversible reaction again turns the ozone into oxygen through absorption of longer ultraviolet rays. The strength of the absorption of solar energy is proportional to the wavelength and absorption bands that are formed at regions of strong absorption. The examples of important atmospheric gases forming part of absorption bands are oxygen (O2), ozone (O3), carbon dioxide (CO2), methane (CH4), water vapour (H2O), nitrogen dioxide (NO2) and chlorofluorocarbons (CFC).

11. Sensors and Transducers for a Human Brain

Your body has feedback systems that regulate the internal environment of your body. The feedback systems make use of storage depots and numerous feedback loops. The monitoring of plasma calcium is a good example of negative feedback. The bones constitute large storage depots for calcium, for the plasma to withdraw these storage supplies in times of need. Our body’s homeostatic regulatory systems are represented by feedback loops. The feedback is considered negative, when it is compensating or negates any change. The negative feedback is essential to stabilize a system.

The gastrointestinal tract, the lungs, the kidneys, and skin of your body make exchange of materials and energy between the internal and the external environments. A steady state is achieved by regulatory mechanisms involving the balance between the inflow and outflow of the internal environment that stabilizes the composition of the internal environment. The tendency to regulate the internal environment so that it is maintained in a steady state is called homeostasis [1, 7].

11.1. Heat Stress

When vulnerable to solar radiation, your body acts as a solar energy absorber. This enables your senses for interpretation of our surrounding environment. The amount of heat you lose is dependent on the difference in temperature between the environment and the surface of your body. The heat loss from your body is directly proportional to this difference in temperature. The heat would be released from your body, if the surface temperature of your body is at a higher level than that of the environment. If due to excessive solar radiation, the environmental temperature rises above your body temperature, you will gain heat from the environment.

11.2. Effects of Intense Heat in a Room

Your presence in a room with solar radiation, high room air temperature and conduction do not count in your favour for loss of body heat. In this situation, your body gain heat from the surrounding environment. You have the chance to survive, but only through mechanism of sweating for losing heat. The normal response of your body is resulting in intense heat strains through the body’s circulatory system. This happens because the hypothalamus reacts to the heat through expansion of the blood vessels in your skin. As a consequence, it results in decreased resistance to blood flow and your blood pressure falls. The reflexes happen, which prevent large changes in blood pressure, ultimately begin to operate and the decreased resistance to blood flow is compensated through the heart working much harder. The expanded blood vessels create it potential for large amounts of blood to pool in the vessels of your skin at the price of other organs. You will faint as a result of sufficiently low blood supply to your brain.

11.3. Sweating

Through sweating, a circulatory problem occurs, because of the salt and water loss. A decreased plasma volume occurs because of excessive fluid loss. As a result, the output of blood from the heart is slowed down, which could lead to decreased blood flow to the skin, which ultimately could reduce sweating. If this occurred, your main avenue for heat loss would be shut down. In this case, heat production would continue and your body temperature would rise until your whole body system is collapsed. The body’s ability to control heat loss is very limited. A vicious circle may occur as a result of heat not losing rapidly enough to prevent a rise in body temperature. When heat regulation fails, the positive feedback loop occurs into operation in your body (Heat production – metabolism – temperature control); if unchecked it results in heat stroke and death.

11.4. Evaporation

Sweating is an evident method to lose heat by evaporation. Water continuously evaporates from your skin during the process of sweating. When you breathe, there is also a small loss of water from the surface of the lungs. When you breathe or sweat, the amount of water that evaporates is proportional to the humidity of the air. At high humidity of the surrounding air, water evaporates much slowly and therefore contributes less to the cooling process. One of the important methods of losing heat from the surface of your body is through evaporation. There is evaporation of water from your skin after swimming and you feel cool. There should have minimum amount of energy of the water molecules on your body’s surface for evaporation to happen. The speeding water molecules on the surface of skin beat the forces holding them in the liquid state. This finally results in evaporation into the air as water vapour molecules. The cooler molecules are left behind in the whole process. As a result, heat pours from the warmer surface of your skin to the cooler water molecules. This heat flow transfers energy to the water, increasing the number of evaporating water molecules. Furthermore, the cooling of your skin also cools any underneath blood which tends to flow through that part of your body.

11.5. Protection through Noise Filters

The keeping of face beard (facial hair) and wearing of a knitted head cloth (patka) and a turban (pag) on your body has a logical and a scientific significance. The daily self-making folds of hair knots and making round folds of turban over the head of your body with colourful cotton cloths has following historical, medical benefits: i) it indicate, protects and concentrate the disciplinary physical and mental strength of a person; ii) it gives hair tonic to the growth of hairs on your body due to solar energy; iii) the whole system acts as noise filter and provides immunity to your body; and iv) the folded Patka with style, folded design of hair knots on top of your head is your identity in time domain, the face beard on your body is a measuring ration and a sign of man, the turban with style, colour, design is your identity in space domain.

12. Comfort and Health

The ASHRAE handbook of fundamentals has provided a detailed discussion of the physiological principles of human thermal comfort [37]. The amount of heat generated and dissipated by your body varies considerably with activity and age as well as with size and gender. The complex regulatory system of your body act to maintain the temperature of your body to about 36.9 °C regardless of the environmental conditions.

The environmental factors that affect thermal balance of your body for influencing thermal comfort are [38]: i) the dry bulb temperature of the surrounding air; ii) the humidity of the surrounding air; iii) the relative velocity of the surrounding air; iv) the temperature of any surfaces that are in direct view to any part of your body and thus exchange radiation. In addition the personal variables that affect the thermal comfort of your body are activity and clothing. The physiological mechanisms that your body uses to control your body temperatures are metabolism, blood circulation, near the surface of the skin termed as cutaneous blood circulation, respiration and sweating. The metabolism rate determines the rate at which energy is converted from chemical to thermal form within your body and blood circulation controls the rate at which the thermal energy is carried forward to the surface of your skin. In respiration, air is taken in at ambient conditions but leaves saturated with moisture and very near the temperature of your body. The sweating has a significant effect on the rate at which energy is carried away from the skin of your body by heat and mass transfer.

The energy generated by metabolism rate of your body varies considerably with the activity of your body. A unit to express the metabolic rate per unit of area of your body is termed as met (1 met = 58.2 W m-2), defined as the metabolic rate for your body while seated quite (called sedentary). The variable which affects the comfort of your body is the type and amount of clothing that you are wearing. The insulation of clothing is defined as a single equivalent uniform layer over your whole body. The insulation value for clothing of your body is expressed in terms of clo units (1 clo=0.155 m2CW-1). A heavy business suit with accessories has insulation value of 1 clo, whereas a pair of shorts has 0.05 clo. ASHRAE Standard 55 provides comfort conditions for an acceptable thermal environment [38]. The most comfort studies involve use of the ASHRAE thermal sensation scale. The scale relates words describing thermal sensations to a corresponding number. These are enumerated below:

+3 hot

+2 warm

+1 slightly warm

0 neutral

-1 slightly cool

-2 cool

-3 cold

The operative temperature is the average of the mean radiant and ambient air temperatures, weighted by their respective heat transfer coefficients. Energy balance equations are developed that use a predicted mean vote (PMV) index. The PMV index predicts the mean response of a large group of persons. The coordinates of the comfort zones are:

Winter: Operative temperature of 20 to 23.5 °C at 18 °C wet bulb temperature; operative temperature of 20.5 to 24.5 °C at 2 °C dew point.

Summer: Operative temperature of 22.5 to 26 °C at 20 °C wet-bulb temperature; operative temperature of 23.5 to 27 °C at 2 °C dew point.

The loss of hearing is a serious occupational hazard. Factory workers, truck drivers and other workers are exposed to noise levels that are harmful. The continuous exposure to harmful noise level results in hearing impairment of your ear. The federal Occupational Safety and Health Administration (OSHA) in the Department of Labour has maintained noise exposure limits. The noise exposure is expressed in daily noise for an 8-hour shift.

13. Discussions

13.1. Experiments

The electrical characteristics that were obtained for a pair of glass coated PV modules with indoor experiments under standard operating conditions were performed under ideal conditions. The ideal test conditions gave inconclusive characteristics which certainly are not suitable for consideration during design of PV module system connected to buildings. Additional information under available operating conditions was essential for system design of the PV module system. The results of outdoor experiments revealed that thermal characteristics of PV modules were improved with a glass coating. There was considerable loss in generation of electrical power from a pair of glass coated PV module in comparison to typical rated electrical power for a PV module. The glass coating was responsible for increasing thermal storage along the major dimensions of the PV module system. The conduction heat flow along the height of the glass coated PV module resulted in rise of temperature along its height. This resulted in formation of thermal gradients along the volume of PV module system. The original metallic frame of the glass coated PV module was replaced with a wooden frame to minimize the effect of thermal gradients. The insulating panel in the wooden frame was a plywood board filled with polystyrene which is used in a modern building for insulation. A comparison of experimental results of passive and active ventilation envisaged that active ventilation was necessary to reduce high temperatures of PV modules. The heat storage capacities and thermal storage capacities of various components of PV module system were calculated. The major heat storage in the PV module system was due to heat capacities of the insulating panel. The result was loss of heat along the height of the PV module system. The packed polystyrene with loose fills in the plywood board was responsible for increasing thermal storage capacity of insulating panel. The rise in temperature along the thickness was calculated proportionally from the observed temperature rise along the height of the PV module system. Hence, the temperature measurements were also obtained along the volume, viz. height of a PV solar wall system.

13.2. Numerical Model

The temperature plots of Figure 18 and Figure 19 show that there was steep rise in temperature of insulating panel in comparison to glass coated PV module. The air temperature of air passage in the PV module test section was increased considerably due to increase in thermal mass of the PV module system connected to a building.

A periodic solar heat flux was subjected to heat exchange with ambient and heated air in the PV solar wall. With the assumption of lumped parameter applicability in x-direction imposed a very small percentage of error in the solution of the model. More elaborate solution techniques for heat exchange analysis though improve the accuracy of solution method but certainly were not realistic in environmental conditions involving large deviation due to variation in convection heat exchange coefficients but no deviation with simulated periodic variation of solar intensity.

13.3. Composite Waves due to Stresses and Oscillations

The following composite waves are generated due to development of stresses and oscillations on a PV solar wall device with incident short wavelength electro-magnetic waves: (i) due to connected external electrical load, transmission of electrical energy wave; (ii) due to exchange of viscous dissipation with air, the propagation of heat waves at longer wavelength; (iii) due to thermal stress generation with propagation of heat waves, elastic waves are transmitted in a PV solar wall device; (iv) due to combination of stress development with heat waves, elastic waves and applied external source of energy, the fluid surface waves are propagated; (v) due to climate-particle oscillations of wind and fan induced pressure, applied external waves are propagated; In absence of wind and fan pressure, thermosyphon based oscillations are propagated due to thermal buoyancy.