Development and Validation of a Heat Pump System Model Using Artificial Neural Network

Development and Validation of a Heat Pump System Model Using Artificial Neural Network

Volume 2, Issue 3, Page No 182-185, 2017

Author’s Name: Nabil Nassif1, a), Jordan Gooden2

View Affiliations

1Associate Professor, Department of Civil and Architectural Engineering, North Carolina A&T State University, 27411, USA

2Graduate Student, Department of Civil and Architectural Engineering, North Carolina A&T State University, 27411, USA

a)Author to whom correspondence should be addressed. E-mail: nnassif@ncat.edu

Adv. Sci. Technol. Eng. Syst. J. 2(3), 182-185 (2017); ![]() DOI: 10.25046/aj020323

DOI: 10.25046/aj020323

Keywords: Heat Pump, Artificial Neural Network, Air Conditioning

Export Citations

Modeling of direct expansion (DX) air conditioning and heat pump systems can be necessary in developing energy saving methods required to reduce energy consumption in buildings. The artificial neural networks (ANN) can be simple and reliable as compared to traditional methods. A properly trained artificial neural network can provide accurate results, while being relatively straightforward and easy in development. This paper discusses the implementation and validation of an artificial neural network modeling technique to predict the performance of a DX air conditioning and heat pump. The model predicts the compressor power as a function of airflow rate, humidity ratio, ambient and mixed air temperatures. Three different leaning algorithms were compared and validated versus the actual data using statistical indexes to determine the most accurate model structures. Experiments were conducted on a 3-ton DX split-system heat pump fully implemented. The heat pump ran over the course of several months to obtain a wide range of measurements. The results showed that artificial neural network can provide very accurate predictions and this ANN model technique can effectively be used for many energy-efficiency heat pump applications.

Received: 11 March 2017, Accepted: 09 April 2017, Published Online: 24 April 2017

1. Introduction

As energy concerns continue to grow, the need for developing more efficient building energy systems has increased. The global contribution from buildings toward energy consumption, both residential and commercial, has steadily increased over the years, with estimates between 20% and 40% in developed countries [1]. Unitary air conditioning and air-source heat pump systems are one of the most common energy systems for both commercial and residential HVAC applications in USA. Those systems can provide the desired thermal comfort for various building types and sizes. Significant advancements have been made in the design of air conditioning and heat pump systems, including advanced cycle components with support for new refrigerants, improved cycle designs, and expanding their range of applications. One study found the potential to reduce energy consumption by up to 80% through the development of better compressor technology [2]. Many of these systems in use today are designed improperly, and with newer systems becoming increasingly complex; more effective modeling methods are required [3].

Modeling of DX air conditioning system that can be integrated into many energy solution tools is necessary to reduce energy operation cost of those systems [4].

This paper proposes the use of data-based model using artificial neural networks to accurately predict the performance of heat pump systems. The artificial neural network capabilities were extended from linear to nonlinear domains in 1974, for developing a method as general as linear regression with nonlinear capability [5]. Artificial neural network modeling has become increasingly popular for a variety of disciplines, including signal processing and character recognition, stock market prediction, logistics, among others. The main advantages of ANN modeling compared to other methods such as expert systems are its simplicity, speed, and ability to handle a multivariable problem to solve complex relationships between variables. Over the last two decades, the use of ANN systems in HVAC system field has been steadily increasing to solve these complicated problems [6-8]. Bachtler and others used a generalized radial basis function neural network for predicting the steady-state performance of a vapor-compression liquid heat pump [8]. Nassif predicted and optimized various HVAC systems using artificial neural networks and genetic algorithm [4,9].

The proposed modelling technique was tested by performing experiments on a 3-ton DX split-system heat pump. The experiment was prepared utilizing a specially integrated unit in a controlled setting. The heat pump ran under various outside conditions and in heating and cooling modes under. Various ANN model structures and training algorithms were tested and evaluated.

2. Artificial Neural Network

Artificial Neural Networks (ANNs) are non-linear mapping structures that are based on the principle functions of the human brain. They are extremely powerful tools for modeling, especially when the mathematical relationship of a given data is unknown, or not easily discerned. Over the years, they have become the focus of attention, largely due to their wide range of applicability and the ease in which they can work with complicated problems. ANNs are capable of identifying and learning correlated patterns between the input data sets and corresponding target values. After training, ANNs can be used to predict the outcome of new independent input data. They have been used for a large number of applications where statistical methods are traditionally used. Neural Network models are now being employed to solve problems, where in the past was normally solved through logistic regression, multiple regressions, Bayes Analysis and other classical methods. They consist of simple computational units called perceptrons, which are also known as neurons, which are highly interconnected.

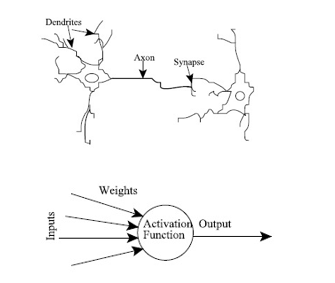

While in actual neurons the dendrite receives electrical signals from the axons of other neurons, with artificial neurons these electrical signals are represented as numerical values. At the synapses between the dendrite and axons, electrical signals are modulated by various quantities. This is also modeled in artificial neurons by multiplying each input by a value called the weight. The higher a weight of an artificial neuron is, the stronger the input which is multiplied by it will be. The calculated weighted sum of the inputs represents the total strength of the input signals. This is then applied to a step function (also known as a Sigmoidal Function) to the sum to determine its output. The weights in most neural networks can be either positive or negative, which have activation or inhibitory influence to each input. Fig. 1 shows an artist conception of a natural neuron (top) and an artificial neuron (bottom). Artificial neural networks need appropriate learning algorithms to be trained. Three learning algorithms were tested: (1) Levenberg Marquardt, (2) Bayesian Regulation, and (3) Conjugate Gradient algorithm. The MATLAB ANN toolbox was used in this study.

3. Experimental Setup

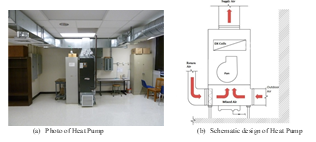

The experimental tests were conducted on a typical heat pump fully instrumented and installed in the HVAC laboratory located at North Carolina A&T State University. This laboratory is equipped with a fully integrated 3-ton DX split-system air conditioning AC as shown in Fig. 2 and controlled by Building Automation and Control network (BACnet) building automation system (BAS). The BAS collects measurement data of nearly all components, including the required measurements such as the outdoor air conditions, temperature and humidity ratio entering and leaving the DX coil, airflow rates, damper positions, and compressor power. Airflow can be changed by varying the position of the return and outside dampers. The airflow through the variable air volume (VAV) box is controlled by two DDC PID cascade control loops; the first control loop determines the set point of airflow rate, and the second controls the VAV damper position. The data collected from BAS can be accessed online, or from a device connected directly to the server’s network. The heat pump ran at various intervals covering a wide range of operation conditions. The data collected were the airflow rate, outside, supply, and mixed dry-bulb temperatures, humidity ratio, and compressor power. The ANN developed uses the airflow rate, outside mixed air temperatures and humidity ratio as model inputs. The ANN model outputs were the supply air temperature and compressor power, which were consequently designated as the target variables. In the heating mode, the same input variables applied, except the humidity ratio, as it was not a factor in effecting compressor power or supply air temperature. The artificial neural networks ran multiple times using three different training algorithms, and by varying the number of neurons. These results were then compared against the actual data to determine the most accurate neural networks and model parameters.

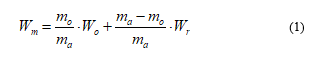

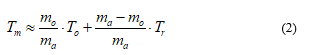

The heat pump was first tested to check if its components are all working appropriately. It was found that the mixed air temperature sensor gave readings higher than expected one on the system monitor. This is a common mixed air temperature reading problem in many DX systems. A study conducted by Avery [10] found that mixed air temperature sensors are often unreliable, due to air stratification and the accompanying design documents which rarely detail proper sensor installation. To resolve this problem, the mixed air temperature Tm and humidity ratio Wm are calculated by applying energy conservation equation as function of outdoor air humidity W0 and temperature T0 and return air temperature Tr and humidity ratio Wr:

Where the ma is mass flow rate of the supply air and mo is mass flow rate of outdoor air. The equations 1 and 2 are applied only when the difference between the return air temperature Tr and outdoor air temperature To is relatively large (higher than 5 oF).

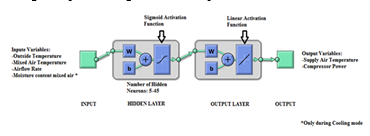

To test neural network model, a wide range of operating performance data is needed. Therefore, the system was run at different outside conditions and various times of the year to have more extreme outdoor conditions. At different conditions, the heat pump ran for a few hours, this repeats throughout the months of April through September. The building automation system was set to record the measurements every five-minute interval, and more than 891 performance data points were collected. Approximately 618 data points are used to train the ANN. Roughly 70% of each dataset were designated specifically for training, and the remaining 30% used solely for testing. While there are several different model parameters within an artificial neural network which affects its performance, the most significant factors are number of hidden layer neurons and how the training is performed (training algorithm). In this paper, the neural networks as shown in Fig 3 were configured to run under every permutation between the three different training algorithms and different number of neurons, ranging from 5 to 45. Furthermore, these networks were tested using multiple and single variable outputs.

4. Results

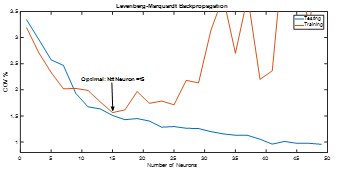

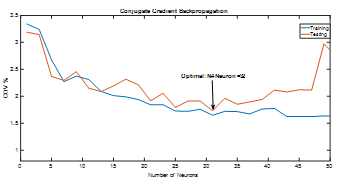

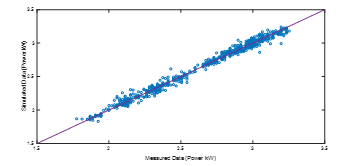

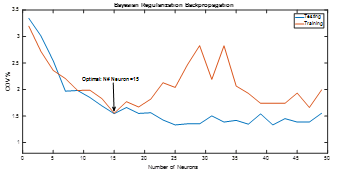

As mentioned before, the 891 performance data points were collected and divided into two sets: (1) training data set (618 data points) and (2) testing data points (273). Three learning algorithms Levenberg Marquardt, Bayesian Regulation, and Conjugate Gradient were used to train the neural network model to predict the DX heat pump power. After completing the ANN training, the model was then tested and evaluated. The evaluations were done by comparing the resulted coefficient of variance (COV) for each model options. The COV is calculated by divided the square mean square error to the mean data. The training and testing are done for various number of neurons to find the best or optimal model. The optimal model is determined based on the lowest COV obtained from the testing data set. Fig.4-6 show the COV results for the training and testing data sets and with various training algorithms.

Fig 5. COV results as a function of number of neurons for Bayesian Regularization training algorithm

By increasing the number of neurons, the COV is decreased for training data set. However, for the testing data set, the COV is decreased and then increased. There is an optimal value of number of neurons with the lowest resulted COV that makes the model predict accurately the power for training data set. The optimal number of neurons are 15, 15, and 32, and the lowest COVs are 1.54%, 1.56%, 1.73% for training algorithms Levenberg-Marquardt, Bayesian Regularization, and Conjugate Gradient. Fig. 7 shows the comparison between the simulated and measured heat pump power. The simulation is done by the ANN model with the optimal number of neurons (#15) and training algorithm Levenberg-Marquardt. These results show that the ANN model can predict accurately heat pump power with COV of 1.54%. The ANN model technique can be used for diffident energy efficiency applications.

5. Conclusion

Various artificial neural network model structure and leaning algorithms were developed and tested. The model predicts the compressor power as a function of airflow rate, humidity ratio, ambient and mixed air temperatures. Experiments were conducted on a 3-ton DX split-system heat pump to collect a wide range of performance measurements. The measurements were divided into training and testing sets. The models were evaluated by comparing the resulted coefficient of variance COV for each model structure and learning algorithm options. The optimal number of neurons are 15, 15, and 32, and the lowest COVs are 1.54%, 1.56%, 1.73% for training algorithms Levenberg-Marquardt, Bayesian Regularization, and Conjugate Gradient. The validation results showed that artificial neural network can provide very accurate predictions and this ANN model technique can effectively be used for many energy-efficiency heat pump applications

Conflict of Interest

The authors declare no conflict of interest.

Acknowledgment

This work was performed under the following financial assistant award 70NANB14D1319 from the U.S. Department of Commerce, National Institute of Standards and Technology.

- Pérez-Lombard, L., J. Ortiz, and C. Pout, “A review on buildings energy consumption information” Energy and buildings 40(3), 394-398, 2008

- Chua, K. J., S. K. Chou, and W. M. Yang, “Advances in heat pump systems: A review” Applied Energy 87(12), 3611-3624, 2010

- Nassif, N., Rice, K., and Shen, B, “Development of a Matlab-Based Integrated Model for Optimal Design and Operation of Heat Pumps”, CD 2015 ASHRAE Annual Conference, Atlanta, GA

- Nassif, N, “Modeling and Optimization of HVAC systems using Artificial Neural Network and Genetic Algorithm”, International Journal of building Simulation 7(3), 237-245, 2014.

- Werbos PJ, “Beyond regression: new tools for prediction and analysis in the behavioral sciences”, Ph.D. dissertation. Cambridge, (MA): Harvard University, 1974.

- Mohanraj M, Jayaraj S, Muraleedharan C, “Energy assessment of direct expansion solar assisted heat pump working with R22 and R407C/LPG mixture”, International Journal of Green Energy (7): 65–83, 2010

- Dauphin, Yann and Bengio, Yoshua, “Big Neural Networks Waste Capacity” University of Montreal, QC Canada. March 2013.

- Bacthler H, Browne MW, Bansal PK, Kecman V. “Neural networks—A new approach to model vapour compression heat pumps”, International Journal of Energy Research (25), 591–9, 2001.

- Nassif, N., M. Arida, and R. Talib, “Development and Testing of Building Energy Model Using Non-Linear Auto Regression Neural Networks”, 2016 ASHRAE Meeting, St Louis, MO.

- Avery, Gill, “Do Averaging Sensors Average?” ASHRAE Journal (12), 42-43, 2002